A kind of brewing process of Jiahu original-flavor liquor

A technology of liquor and craftsmanship, which is applied in the field of Jiahu original-flavor liquor brewing technology, can solve problems affecting health, defects of liquor chemical shape and convenience, liquor color, shape, and smell defects, etc., to achieve long aftertaste, elegant grain aroma, Fragrant natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

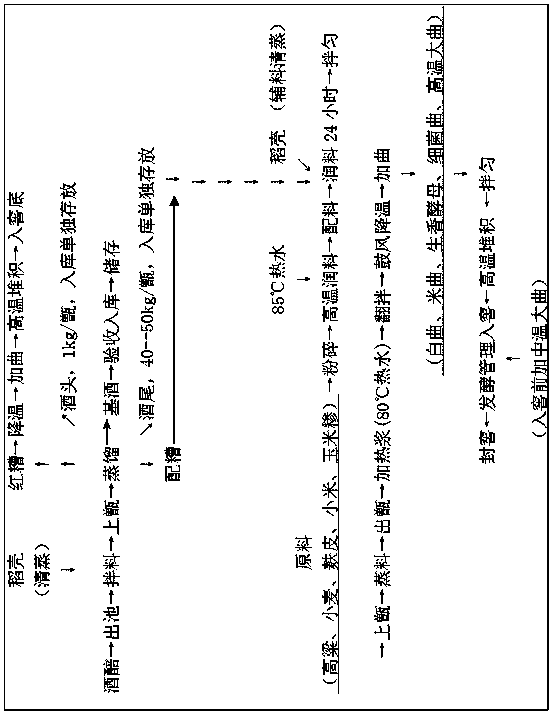

[0019] Such as figure 1 As shown, a Jiahu original-flavor liquor brewing process is characterized in that the process steps are as follows: 1) The wine grains are released from the cellar: remove the insulation material, clean up the sand and soil around the cellar, and put it into the designated In the woven bag for the next use, then remove the plastic cloth, remove the mud on the top of the cellar, and clean it up to prevent the mud from mixing into the wine grains. Conditions for leaving the cellar: moisture 60 to 63%, acidity 4.0 to 4.5 , starch 8 to 10%, alcohol content 4.0 to 5.0%vol; 2) Distillation: take out the fermented grains and transport them to the side of the retort with a small bucket cart, mix in 20kg of cooked rice husks and put them on the retort. When filling the steamer, sprinkle it when it sees the tide, so that it is light, loose, thin, even, gentle and flat. It is required to keep the sides high, medium and low when filling the steamer at the end. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com