Preparation method of organically modified nano-montmorillonite reinforced polyimide fiber

A polyimide fiber and nano-montmorillonite technology, which is applied in the field of functional textile materials, can solve the problems of difficult dyeing of polyimide fibers and limitations of textile applications, and achieve the effect of strong flame retardant function and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

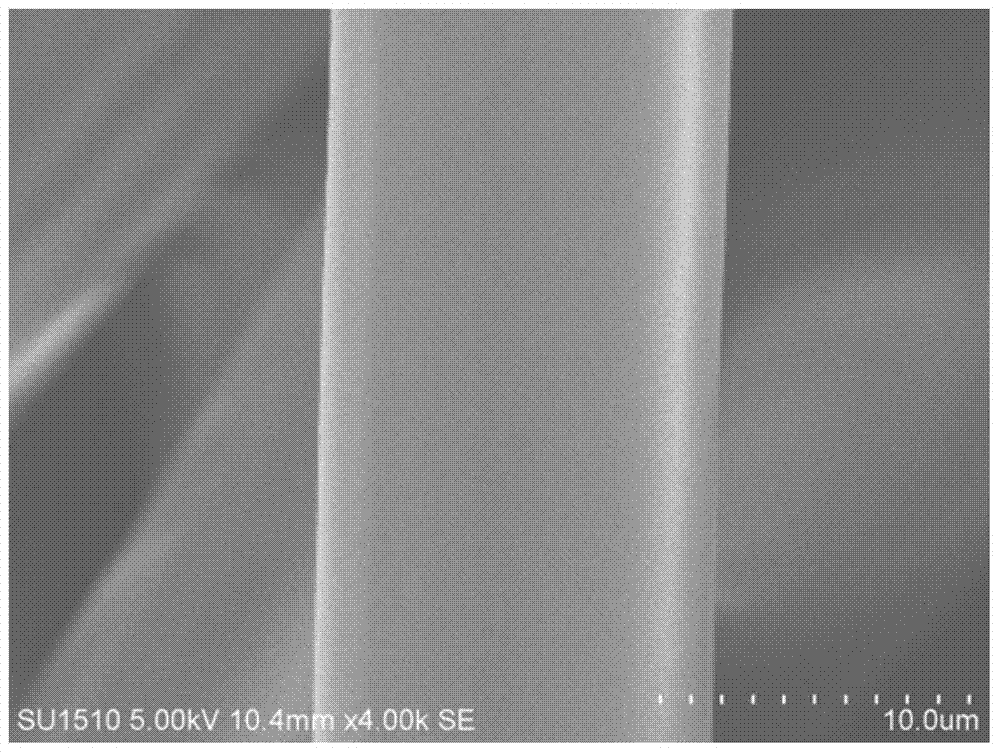

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of organically modified nanometer montmorillonite reinforced polyimide fiber, comprises the following steps:

[0027] (1) Preparation of nano-montmorillonite: commercially available nano-montmorillonite (Zhejiang Fenghong New Material Co., Ltd., product model: BS, JF, HFGEL) is pulverized by jet milling to obtain particles with a particle size less than 100 nanometers. Nano montmorillonite;

[0028] (2) Organic modification of nano-montmorillonite: Add nano-montmorillonite to 3,3′,4,4′-biphenyltetracarboxylic dianhydride solution and p-phenylenediamine solution respectively, and place under magnetic Stir on the stirrer, the speed is 300 rpm, and the stirring time is 12h, respectively prepare 3,3′,4,4′-biphenyltetracarboxylic dianhydride modified nano-montmorillonite and p-phenylenediamine modified nano Montmorillonite; the concentration of the 3,3',4,4'-biphenyltetracarboxylic dianhydride solution and p-phenylenediamine soluti...

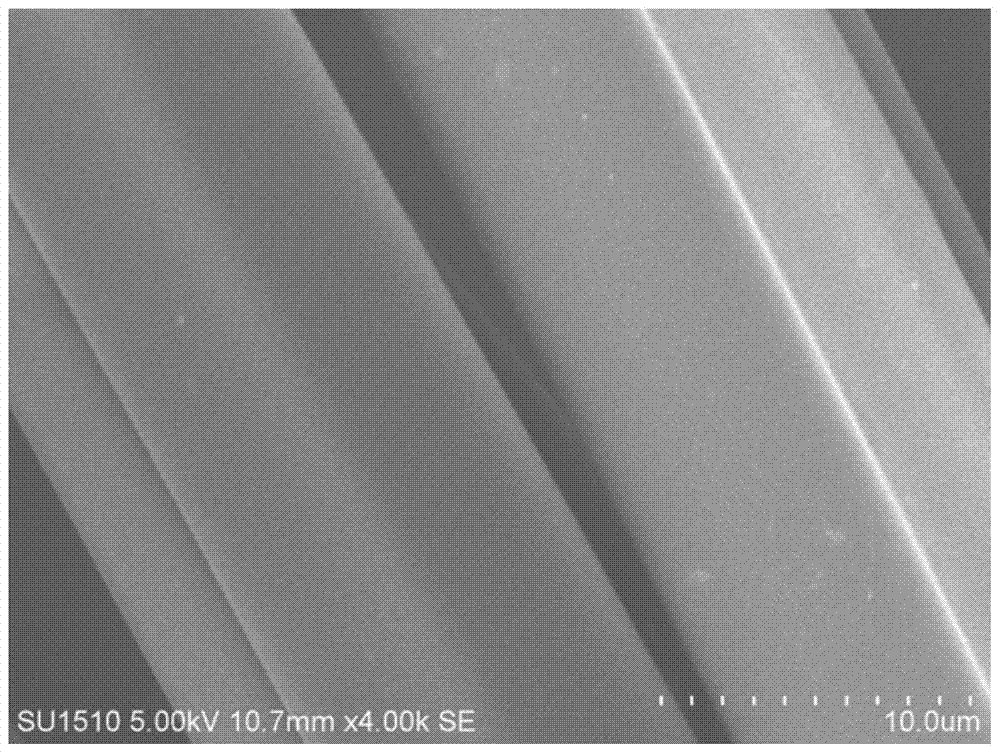

Embodiment 2

[0031] Embodiment 2: a kind of preparation method of organically modified nanometer montmorillonite reinforced polyimide fiber, comprises the following steps:

[0032] (1) Preparation of nano-montmorillonite: commercially available nano-montmorillonite (Zhejiang Fenghong New Material Co., Ltd., product model: BS, JF, HFGEL) is pulverized by jet milling to obtain particles with a particle size less than 100 nanometers. Nano montmorillonite;

[0033] (2) Organic modification of nano-montmorillonite: Add nano-montmorillonite to 3,3′,4,4′-biphenyltetracarboxylic dianhydride solution and p-phenylenediamine solution respectively, and place under magnetic Stir on the stirrer, the rotation speed is 800 rpm, and the stirring time is 4h, respectively to prepare 3,3′,4,4′-biphenyltetracarboxylic dianhydride modified nano-montmorillonite and p-phenylenediamine modified nano Montmorillonite; the concentration of the 3,3',4,4'-biphenyltetracarboxylic dianhydride solution and p-phenylenedia...

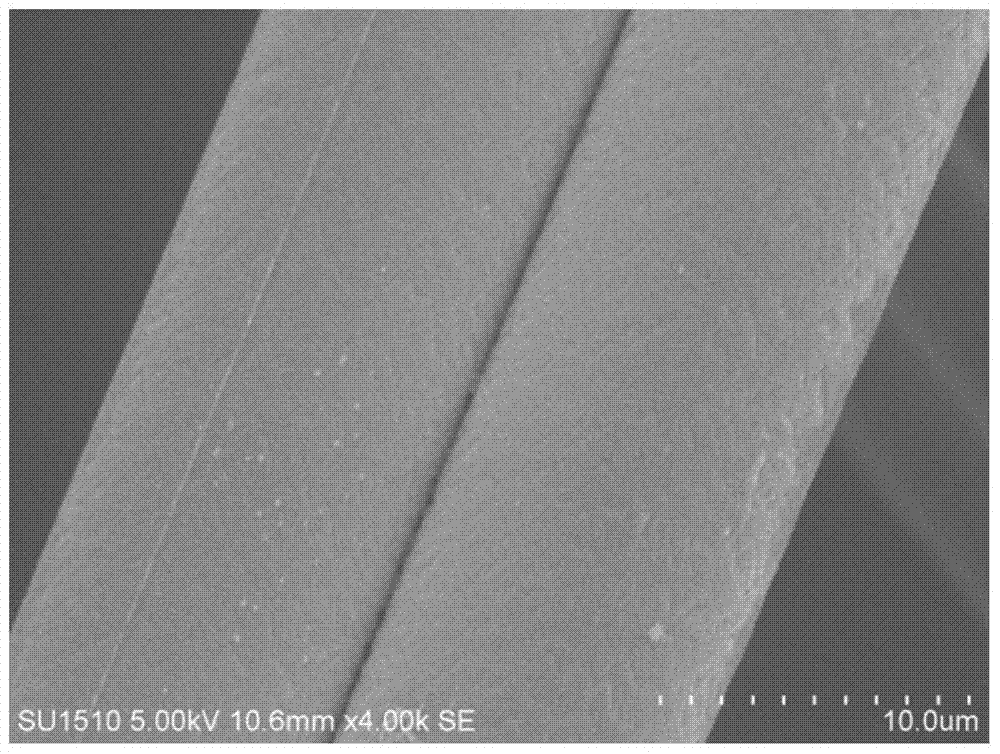

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of organically modified nanometer montmorillonite reinforced polyimide fiber, comprises the following steps:

[0037] (1) Preparation of nano-montmorillonite: commercially available nano-montmorillonite (Zhejiang Fenghong New Material Co., Ltd., product model: BS, JF, HFGEL) is pulverized by jet milling to obtain particles with a particle size less than 100 nanometers. Nano montmorillonite;

[0038] (2) Organic modification of nano-montmorillonite: Add nano-montmorillonite to 3,3′,4,4′-biphenyltetracarboxylic dianhydride solution and p-phenylenediamine solution respectively, and place under magnetic Stir on the stirrer, the speed is 500 rpm, and the stirring time is 8h, respectively prepare 3,3′,4,4′-biphenyltetracarboxylic dianhydride modified nano-montmorillonite and p-phenylenediamine modified nano Montmorillonite; the concentration of the 3,3',4,4'-biphenyltetracarboxylic dianhydride solution and p-phenylenediamine solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com