Preparation method of hyperbranched compound modified dyeable polyimide fiber

A technology of polyimide fiber and polyimide, which is applied in the field of preparation of dyeable polyimide fiber modified by hyperbranched compounds, can solve the problems of limited application of textiles and difficult dyeing of polyimide fiber, and achieve Improve wearing comfort, improve antistatic performance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

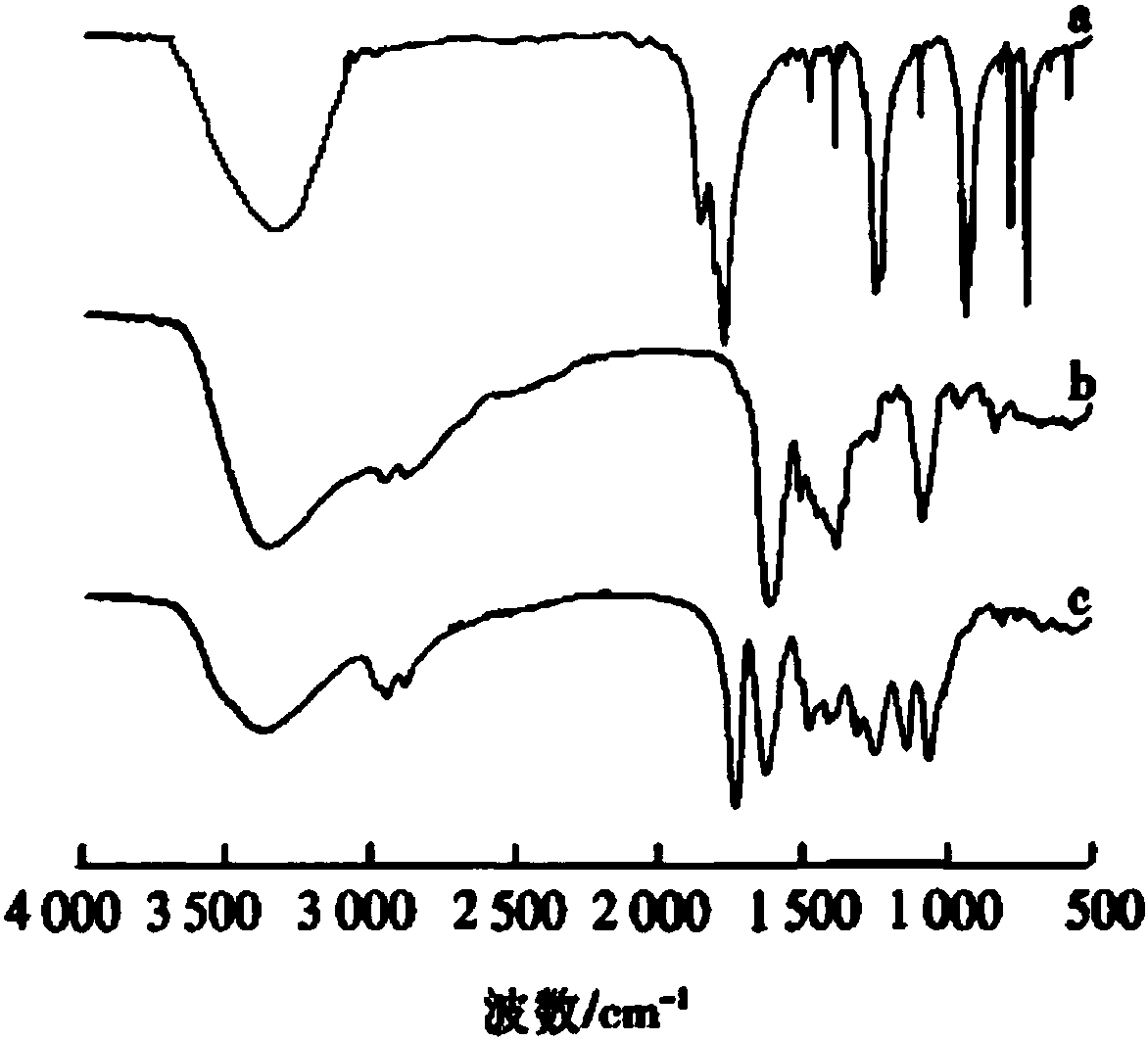

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of hyperbranched compound modification dyeable polyimide fiber, comprises the following steps:

[0028] (1) Mix 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BPDA) and triaminobenzene according to the molar ratio of anhydride and amino group of 1:2, and carry out polymerization reaction in a polymerization kettle at a reaction temperature of 60 ℃, the reaction vacuum is less than 0.1 atmospheric pressure to ensure that the water generated by the reaction is drawn out, which is beneficial to the positive reaction. The reaction time is 9 hours, and the hyperbranched compound is prepared;

[0029] (2) The hyperbranched compound obtained in step (1) is purified by filtration, and added to the polyimide polymerization solution for polymerization reaction, the polymerization reaction is protected by nitrogen, the polymerization temperature is -5 ° C, and the polymerization reaction time is 10 hours; The polyimide polymerization solu...

Embodiment 2

[0033] Embodiment 2: a kind of preparation method of hyperbranched compound modification dyeable polyimide fiber, comprises the following steps:

[0034] (1) Mix 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BPDA) and triethanolamine according to the molar ratio of anhydride and amino group at 2:1, and carry out polymerization reaction in a polymerization kettle at a reaction temperature of 180°C , the reaction vacuum is less than 0.1 atmospheric pressure to ensure that the water generated by the reaction is drawn out, which is beneficial to the positive reaction. The reaction time is 3 hours, and the hyperbranched compound is prepared;

[0035](2) The hyperbranched compound obtained in step (1) is purified by filtration, and added to the polyimide polymerization solution to carry out polymerization reaction, the polymerization reaction adopts nitrogen protection, the polymerization temperature is 5 ° C, and the polymerization reaction time is 2 hours; The polyimide polymeriz...

Embodiment 3

[0039] Embodiment 3: a kind of preparation method of hyperbranched compound modification dyeable polyimide fiber, comprises the following steps:

[0040] (1) Mix 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BPDA) and diethanolamine according to the molar ratio of anhydride and amino group at 1:1, and carry out polymerization reaction in a polymerization kettle at a reaction temperature of 100°C , the reaction vacuum is less than 0.1 atmospheric pressure to ensure that the water generated by the reaction is drawn out, which is beneficial to the positive reaction. The reaction time is 6 hours, and the hyperbranched compound is prepared;

[0041] (2) The hyperbranched compound obtained in step (1) is purified by filtration, and added to the polyimide polymerization solution to carry out polymerization reaction, the polymerization reaction adopts nitrogen protection, the polymerization temperature is 0 ° C, and the polymerization reaction time is 5 hours; The polyimide polymeriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com