Dead zone length automatic detection method in auto-levelling control for drawing frame

An autoleveling and automatic detection technology, which is applied in the direction of textiles and papermaking, can solve the problems of low autoleveling accuracy, achieve the effects of avoiding errors, improving work efficiency, and realizing precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

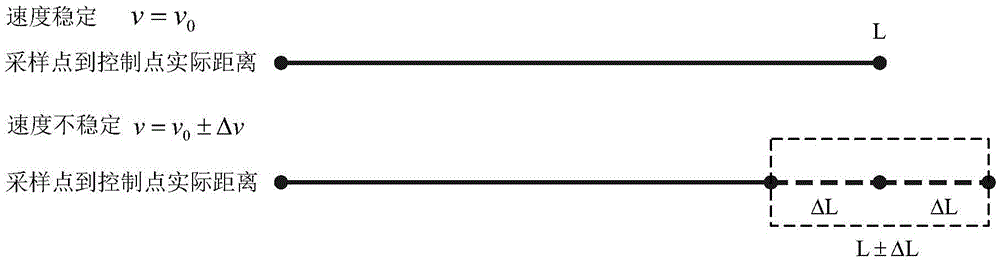

[0013] The automatic detection method of the dead zone length in the autoleveling control of the draw frame. The present invention adopts a fixed length method to determine the length of the dead zone: the control module in the draw frame takes the number of transmission teeth as the unit of measurement, and the control cycle is delayed by N teeth relative to the feeding cycle, and the delayed N teeth are used as the dead zone length.

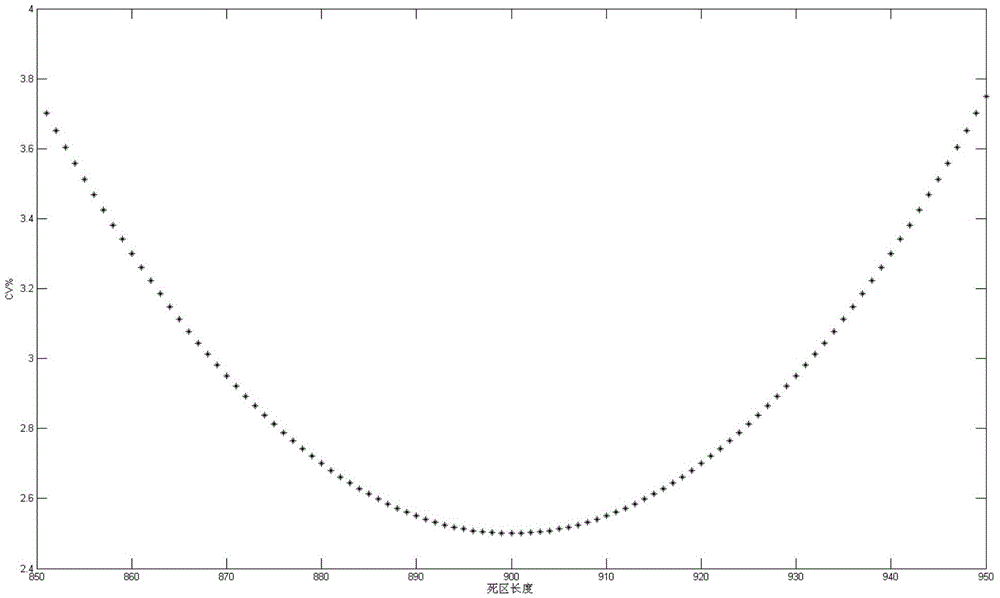

[0014] On the basis of ensuring the stability of the dead zone length, in order to ensure the accuracy of autoleveling, the draw frame can automatically determine the optimal dead zone length. The specific method is as follows:

[0015] Different types of draw frames have their own fixed mechanical distance, which is the recommended dead zone length of the draw frame. Add or subtract a certain length before a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com