Textile fabric cutting machine

A cloth cutting machine and textile technology, applied in the cutting of textile materials, textile and paper making, and sending objects, etc., can solve the problems of affecting the quality of cloth, large manual labor, and low level of automation, so as to reduce the amount of manual operations, Reduced operating time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

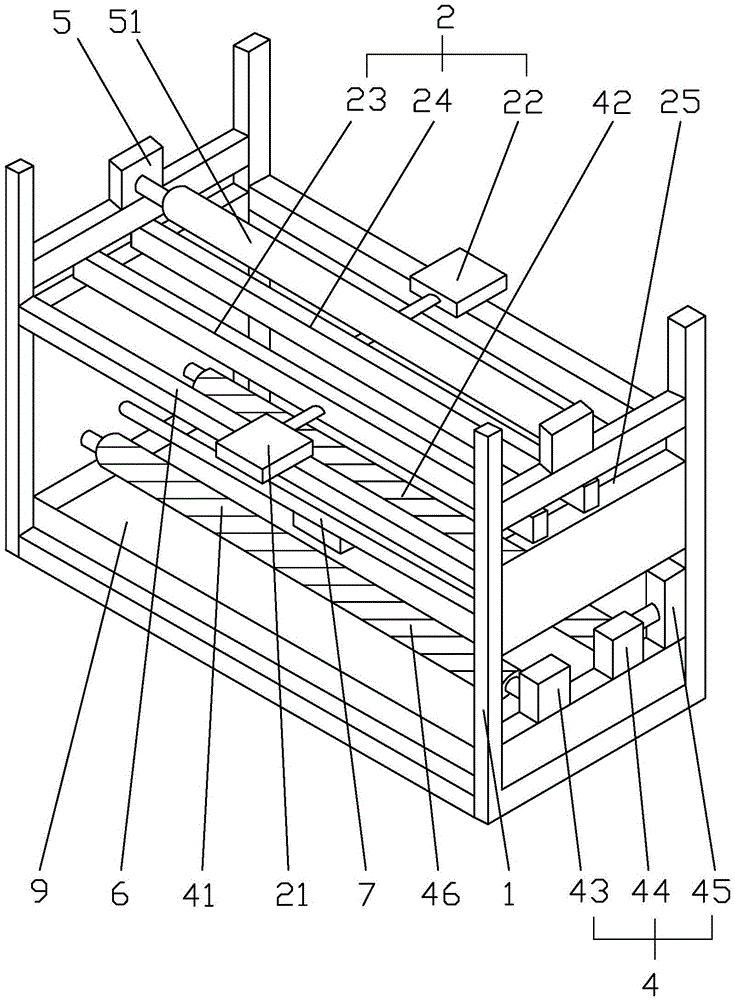

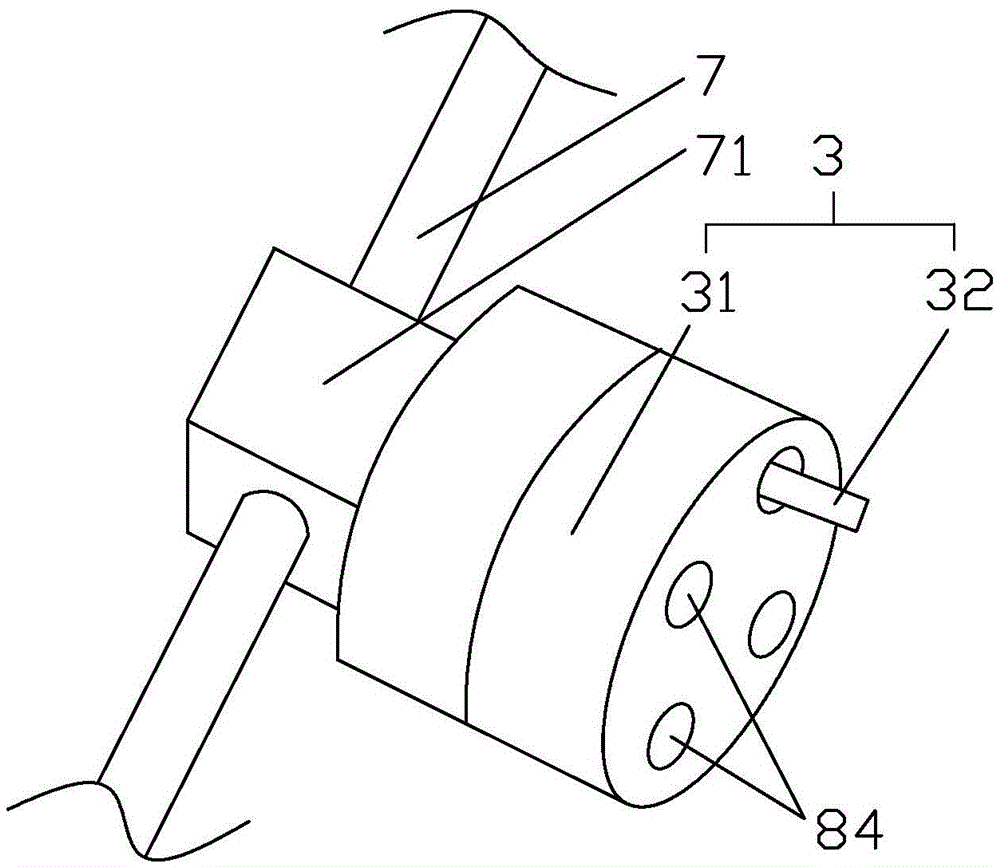

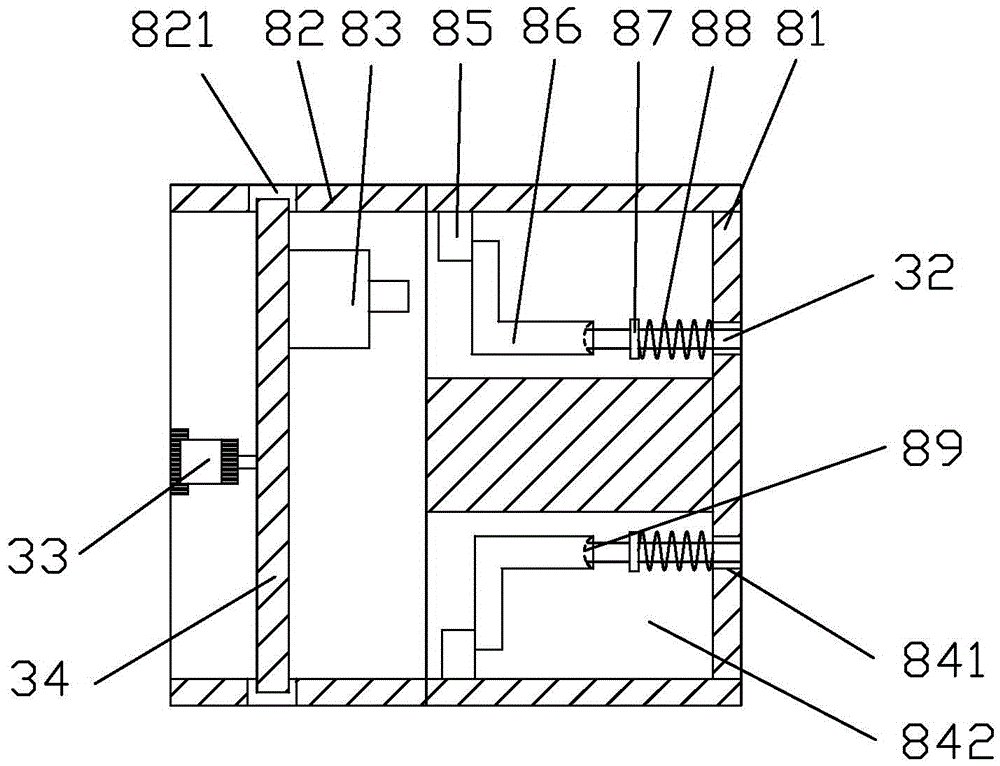

[0017] Such as Figure 1-4 As shown, a textile cloth cutting machine includes a frame 1, a cloth clamping mechanism 2, a cutter 3 and a transmission mechanism 4, and the cloth clamping mechanism 2, the cutter 3 and the transmission mechanism 4 are sequentially arranged on the on rack 1. The upper side of the frame 1 is provided with a support seat 5, and the support seat 5 is provided with a cloth releasing roller 51 for placing the cloth to be cut. Two fixed rods 6 are arranged on the lower side of the cloth releasing roller 51 on the frame 1 , and the cloth clamping mechanism 2 is located on the fixed rods 6 . The cloth clamping mechanism 2 includes a first hydraulic cylinder 21, a second hydraulic cylinder 22, and a first cloth clamping rod 23 and a second cloth clamping rod 24 respectively arranged on the piston rods of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com