Balance weight buffering type height limiting frame

A technology of weights and height-limiting rods, which is applied in the direction of restricting traffic, roads, road safety devices, etc., can solve the problems of not attracting the driver's attention, easily bumping into the height-limiting frame, and increasing maintenance costs, so as to ensure personal safety and Effects of public facility safety, reduction of maintenance and repair costs, and reduction of accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

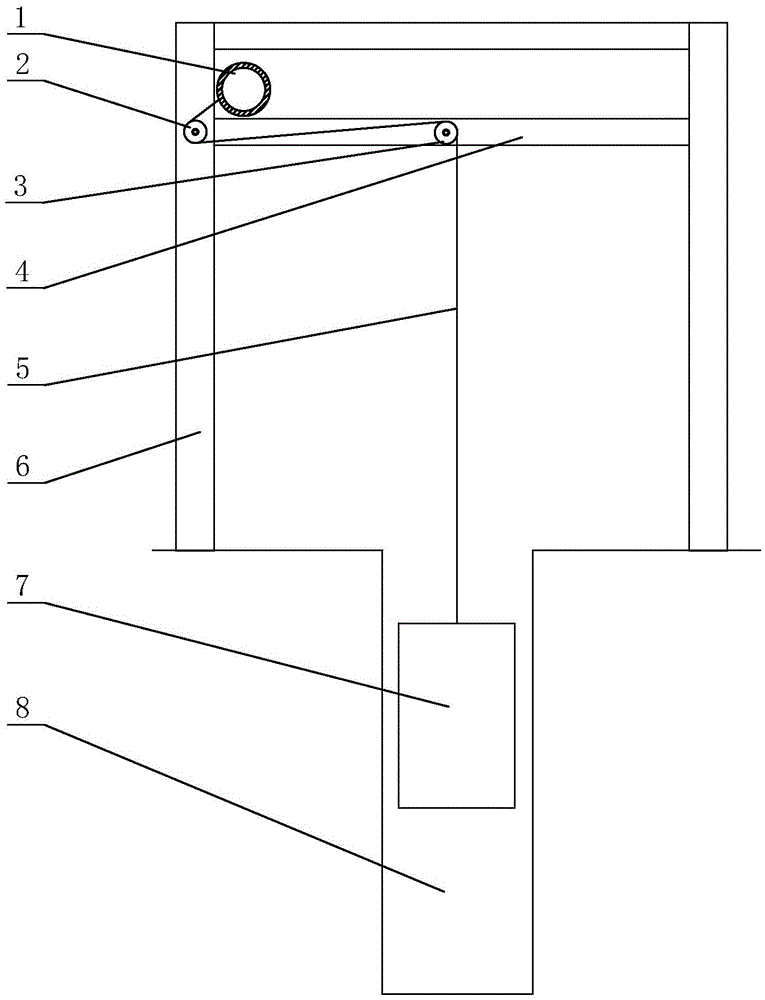

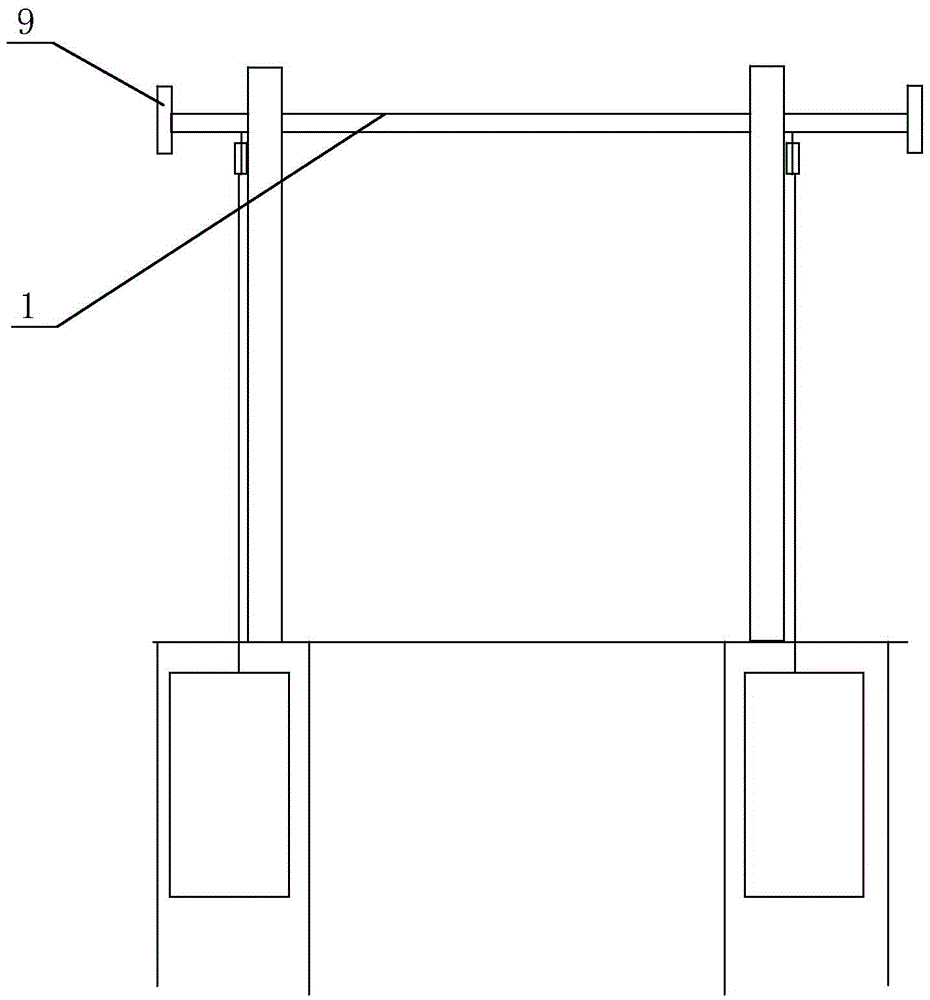

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0020] like figure 1 and figure 2 As shown, the pendant buffer type height-limiting frame of the present invention includes uprights 6 separated on both sides of the road, and guide rails are respectively fixed at the upper ends of the two uprights 6, and the two guide rails are parallel. The No. 1 pulley 2 and the No. 2 pulley 3, wherein the No. 1 pulley 2 is in front of the original position of the height-limiting pole 1, and one end of the steel cable 5 is fixed on the height-limiting pole 1, and the other end goes around the No. 1 pulley 2 and the No. 2 pulley respectively 3 connects the weight 7, and the weight 7 is placed in the deep well 8 below the No. 2 pulley 3.

[0021] Working principle and process:

[0022] Under normal conditions, the gravity of the weight 7 pulls the height limiting rod 1 to the front end (initial position) of the slide rail 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com