Novel heat insulation composite plate

A thermal insulation composite board, a new type of technology, applied in the direction of thermal insulation, building components, layered products, etc., can solve the problems of high material cost, lack of thermal insulation and sealing performance composite board, complex construction, etc., to achieve good sealing performance, easy to assemble and connect, Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

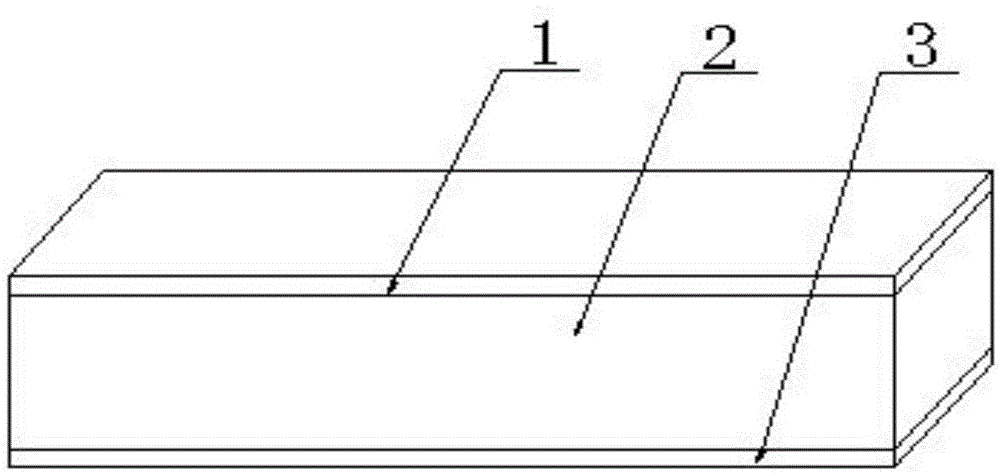

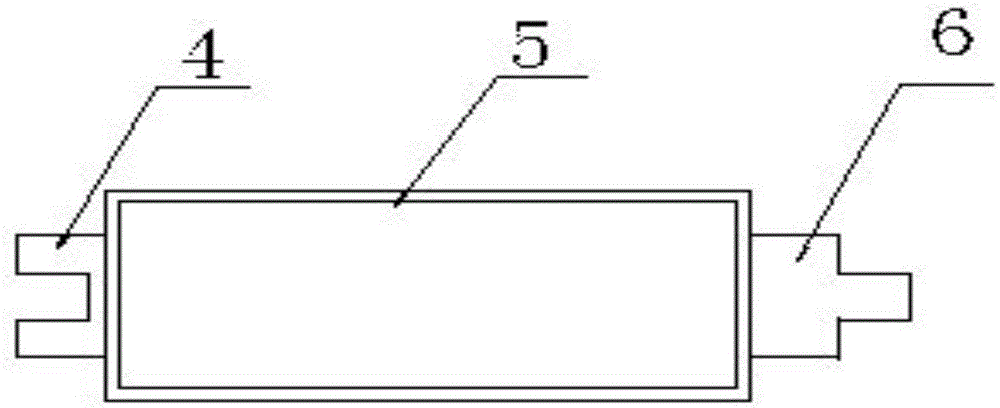

[0020] The main structure of this embodiment, such as figure 1 , figure 2 As shown, a new type of thermal insulation composite board, the thermal insulation composite board includes a polyurethane foam layer 2, and tempered glass 1 and a coated steel plate 3 are respectively provided on the upper and lower surfaces of the polyurethane foam layer 2, and the outer side of the thermal insulation composite board is covered There is a layer 5 of polyurethane foam.

[0021] Among them, the connection between the polyurethane foam layer 2 and the tempered glass 1 and the connection between the polyurethane foam layer 2 and the coated steel plate 3 are mainly connected by glue, and are compositely formed by a laminator.

[0022] The outer side of the thermal insulation composite board is covered with a layer of polyurethane foam material 5, which is combined with the thermal insulation composite board to form an integral structure, which can effectively increase the sealing and ther...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, it is further defined that the polyurethane foam layer 2 and the tempered glass 1, the polyurethane foam layer 2 and the coated steel plate 3 are all connected by adhesion. Here, further optimization is mainly made on the connection mode of the polyurethane foam layer 2 and the tempered glass 1, the polyurethane foam layer 2 and the coated steel plate 3, wherein the upper and lower surfaces of the polyurethane foam layer 2 can be stabilized with the tempered glass 1 and the coated steel plate 3 respectively. The connection method of the connection is all within the protection scope of the present invention, and in this embodiment, the connection is preferably by bonding. The other parts of this embodiment are the same as those in Embodiment 1, and are not repeated here.

Embodiment 3

[0026] This embodiment further defines the thickness of the polyurethane foam layer 2 to be 15cm-20cm on the basis of the above embodiment, wherein the thickness of the polyurethane foam layer 2 may also preferably be 15cm or 20cm, which can be selected as required. The other parts of this embodiment are the same as the above-mentioned embodiments, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com