Peanut dried beancurd and production method thereof

A production method and technology of dried tofu, which is applied in the field of food processing, can solve problems such as no public records of dried tofu, and achieve the effects of considerable market prospects, simple production process, and strong taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

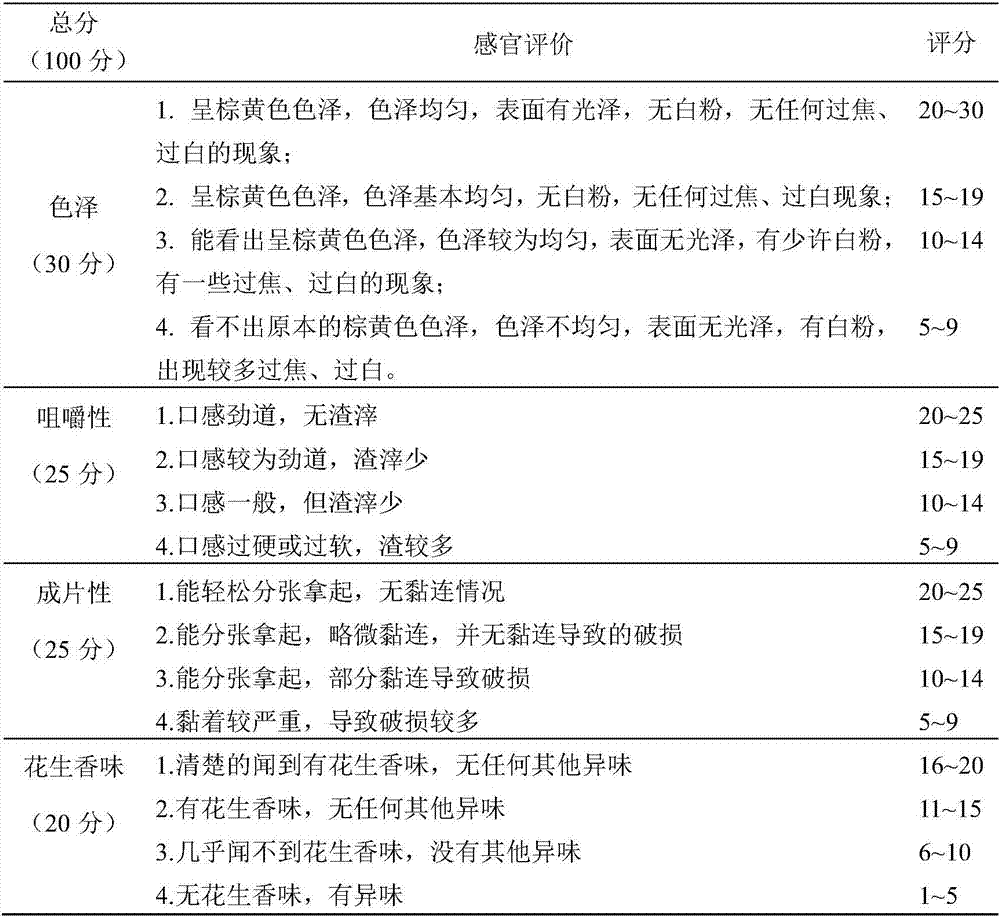

Image

Examples

Embodiment 1

[0023] Embodiment 1 is the best embodiment.

[0024] Soak 100g of soybeans and 25g of raw peanuts in 1000mL of water for 8 hours, and set aside; put 5g of peanuts into an oven, bake at 100°C for 3 minutes, and set aside; put soaked soybeans, raw peanuts, roasted peanuts, and 1100mL of water into a soybean milk machine for grinding and boiling. Pour the boiled soybean milk into the tofu bag and filter to obtain the peanut and soybean slurry; when the temperature of the peanut and soybean slurry is 80°C, add a composite coagulant prepared from 5.535g of brine, 16.605g of calcium carbonate, and 37.86ml of water while stirring, and keep warm Stand still to get the peanut and soybean brain; put the tofu wrapping cloth on the tray, sprinkle the crushed peanut and soybean brain on the tofu wrapping cloth evenly, the thickness of the peanut and soybean brain is 3-4mm, and add another layer of tofu wrapping cloth, just right Cover the top of the peanut and soybean brain that was splash...

Embodiment 2

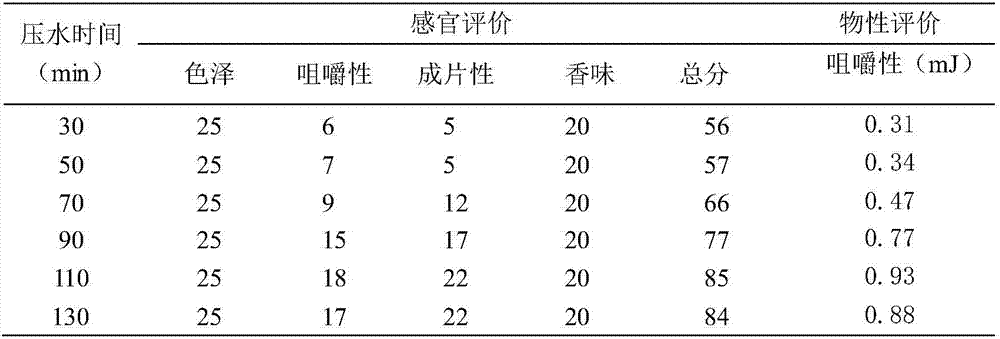

[0027] Embodiment 2 adopts different technological conditions from Embodiment 1——different pressure water time comparison experiments.

[0028] Add 100g of soaked soybeans, 25g of raw peanuts and 5g of peanuts roasted at 100°C for 3 minutes, add 1100ml of water and boil with a soymilk machine, pour the boiled soymilk into a tofu bag and filter to obtain a peanut-soybean slurry, and wait until the temperature of the peanut-soybean slurry is 80 At ℃, while stirring, add a composite coagulant made of 5.535g brine, 16.605g calcium carbonate, and 37.86ml water, and keep it warm to obtain peanut soybean brain (if the temperature of the peanut soybean slurry is too low, you can use microwaves at a power of 900W to , heat the peanut and soybean slurry for 2 minutes to boiling, place it at room temperature and cool it to 80°C before adding the composite coagulant). Sprinkle the crushed peanuts and soybean brains evenly on the tofu wrapping cloth, cover the wrapping cloth, repeat the sp...

Embodiment 3

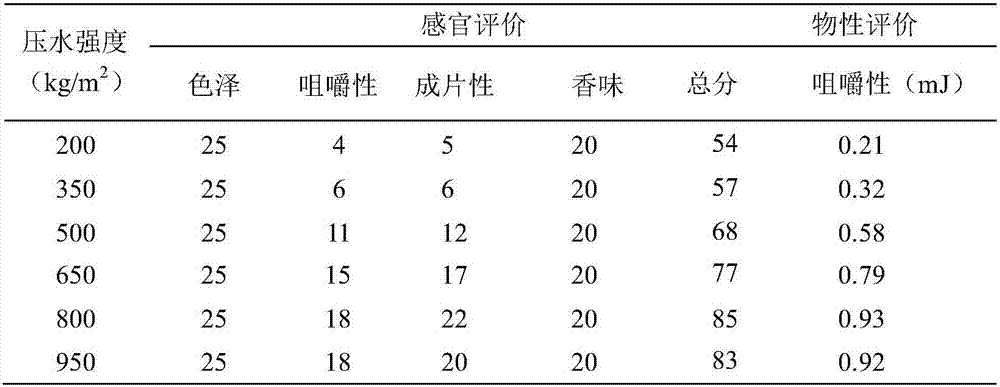

[0032] Embodiment 3 Comparison experiment of different water pressure strengths.

[0033] Add 100g of soaked soybeans, 25g of raw peanuts and 5g of peanuts roasted at 100°C for 3 minutes, add 1100ml of water and boil with a soymilk machine, pour the boiled soymilk into a tofu bag and filter to obtain a peanut-soybean slurry, and wait until the temperature of the peanut-soybean slurry is 80 ℃, while stirring, add a composite coagulant made of 5.535g of brine, 16.605g of calcium carbonate, and 37.86ml of water, and keep it warm to obtain peanut and soybean brain; evenly pour the crushed peanut and soybean brain on the tofu wrapping cloth , cover the bag cloth, repeat the cloth and cloth covering six times, then cover the cover plate, and use heavy objects to adjust the pressure of the peanut and soybean brain to 200kg / m for different components 2 、350kg / m 2 、500kg / m 2 、650kg / m 2 、800kg / m 2 、950kg / m 2 , stand still for 110min, remove the cover plate after the time is up, get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com