Double-acting vacuum pump

A double-acting, vacuum pump technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problem of small maximum vacuum, low pumping rate of vacuum pumps, and failure to meet the brake system requirements of new energy vehicles. Vacuum requirements and other issues, to achieve the effect of reducing noise, large vacuum, and convenient braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

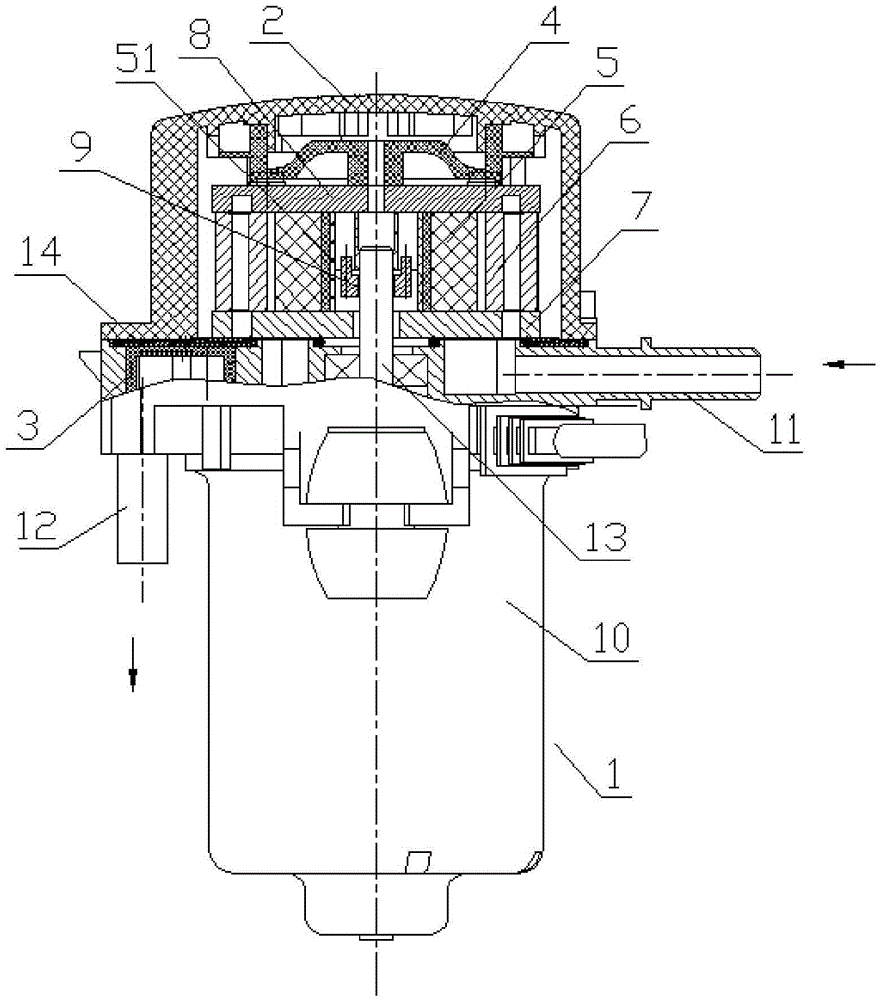

[0032] like figure 1 As shown, a double-acting vacuum pump includes a motor 1 and a double-acting structure driven by the motor 1. The motor 1 includes a motor housing 10, and the head end cover of the motor housing 10 is provided with a cylindrical gland 2. The action structure cover is set in the inner cavity of the gland 2. The head of the motor housing is provided with an air suction hole 11 and an exhaust hole 12. The double-action structure will suck and exhaust when it works, and the air suction hole 11 is used for double-action The air intake of the structure, and the exhaust hole 12 is used for the exhaust of the double-acting structure. After the end face of the gland is connected with the end face of the motor housing head, a seal is formed around the suction hole and the exhaust hole through a sealing ring to avoid air leakage.

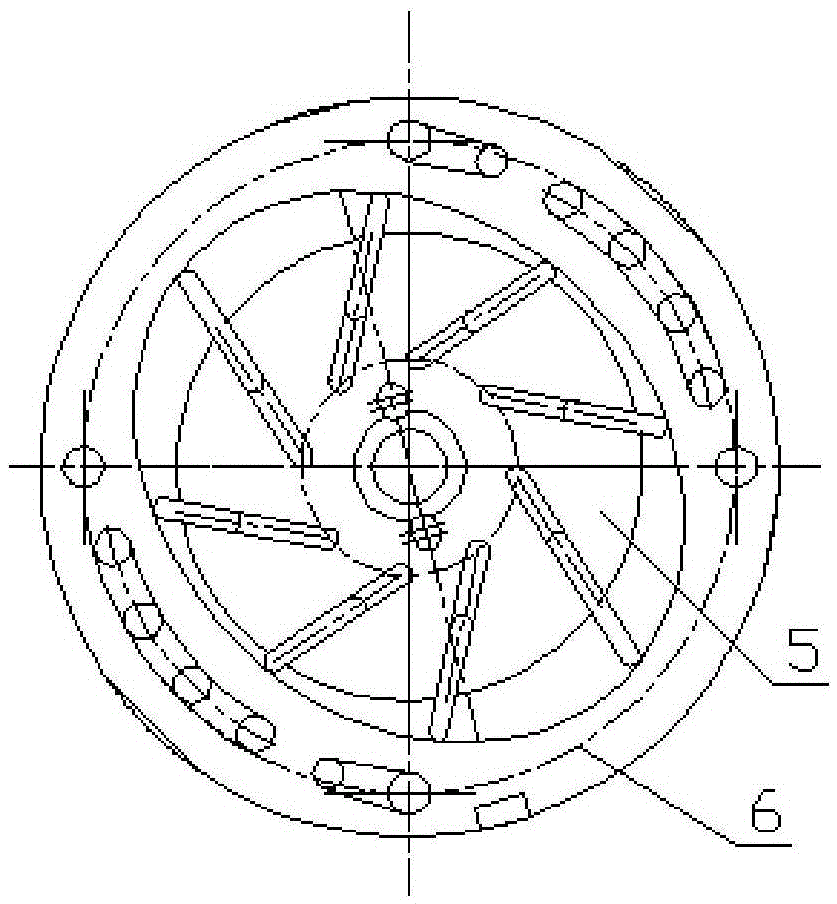

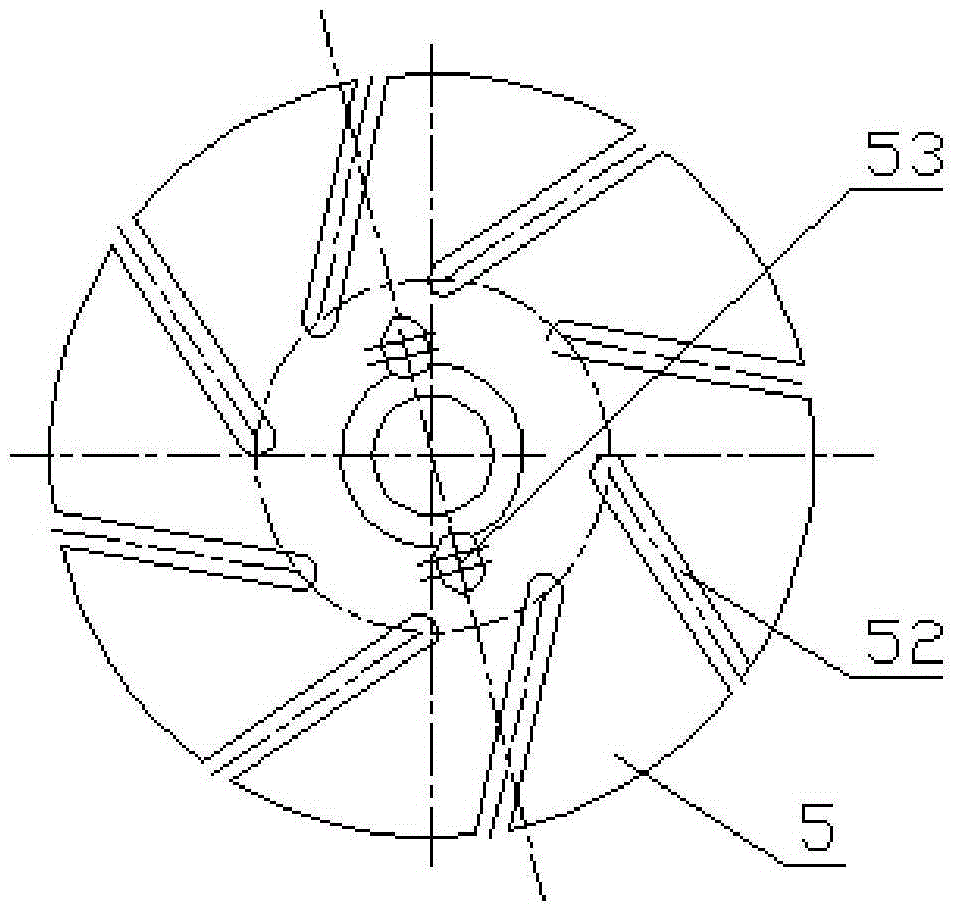

[0033] like Figure 1 to Figure 4 As shown, the double-acting structure includes a stator 6, a rotor 5, a suction disk 7, and an exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com