An operation condition examination method for a metering device

A technology for operating conditions and measuring devices, applied in measuring devices, measuring electrical variables, instruments, etc., to solve problems such as looseness or slippage, inaccurate inspection results of operating conditions, and equipment failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

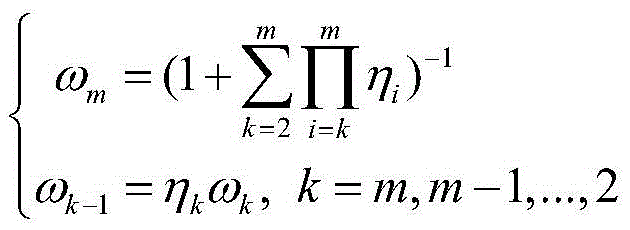

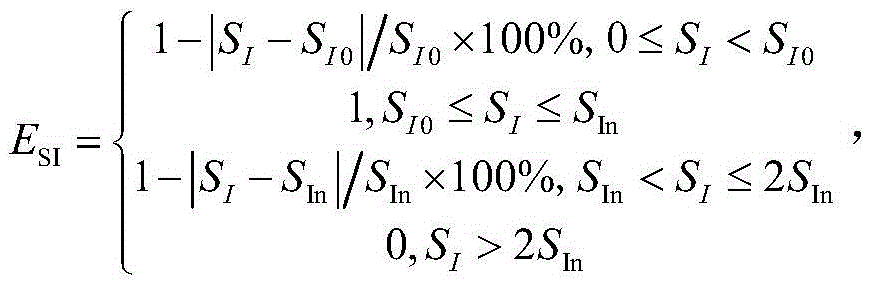

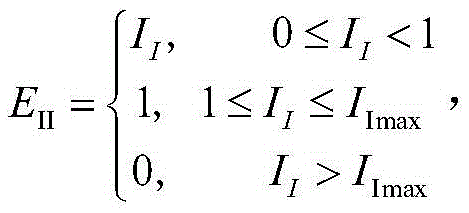

[0064] The operating condition inspection method of the metering device of the present invention comprises the following steps:

[0065] A. Collect the basic information data and on-site operation data of the metering device; the basic information data of the metering device can be obtained through the existing metering production scheduling platform (MDS), and the metering production scheduling platform (MDS) brings together all the basics of metering device supply Information, when collecting the basic information data of the metering device, it is only necessary to call the relevant data stored in the metering production scheduling platform; the on-site operation data of the metering device can be obtained through the existing power consumption information collection system, which can Realize the collection and monitoring of various data such as metering power, operating conditions, and event records of metering devices. Among them, the online monitoring and intelligent diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com