Optical fiber connector and optical contact part module of same

A technology for optical fiber connectors and optical contacts, which is applied in the field of optical fiber connectors and optical contact modules, can solve problems such as inconvenient crimping operations, and achieve the effects of simplifying the assembly process, facilitating operations, and reducing the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

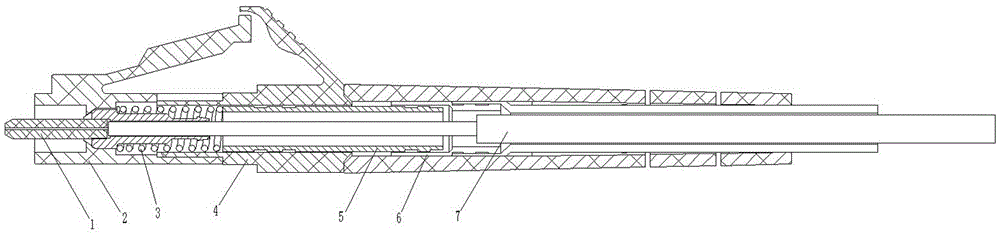

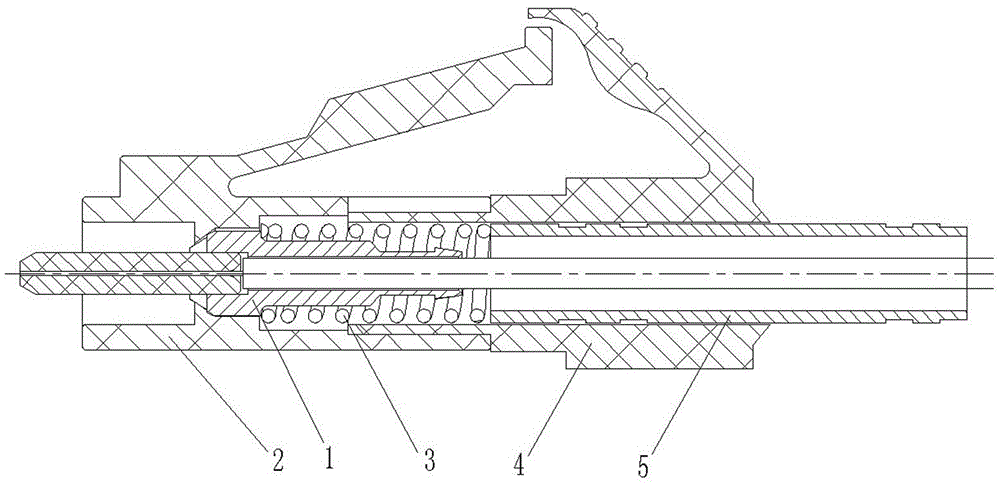

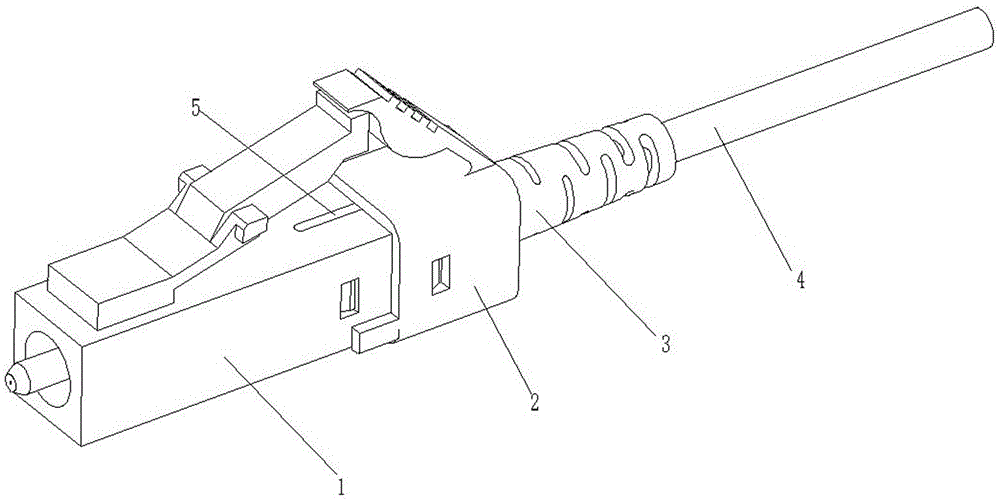

[0032] Embodiment 1 of the fiber optic connector such as Figure 3~10 As shown: the optical fiber connector in this embodiment is an LC optical fiber connector, including a front connector housing 1 and a rear connector housing 2, the front and rear connector housings are square sleeve structures, and the front connector housing 1 is provided with a front connecting housing block 12 on the outer side of the rear end, and the front connector housing 1 is provided with a long slot 5 extending along the front and rear direction from the rear end to the rear end surface of the front connector housing. The setting of the front connector allows the front connector block to move elastically with the front connector housing in the direction perpendicular to the front and back. The rear connector housing 2 is provided with a rear connector housing slot 6. When in use, the rear connector housing 2 Set on the rear end of the front connector housing 1, the front connector housing block 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com