Liquid crystal display panel and quantum rod polaroid manufacturing method

A technology of liquid crystal display panels and manufacturing methods, which is applied in the fields of optics, nonlinear optics, instruments, etc., can solve problems such as difficult development, changing liquid crystal electrical and optical characteristics, etc., to save settings, improve transmittance and brightness, and improve Show the effect of color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

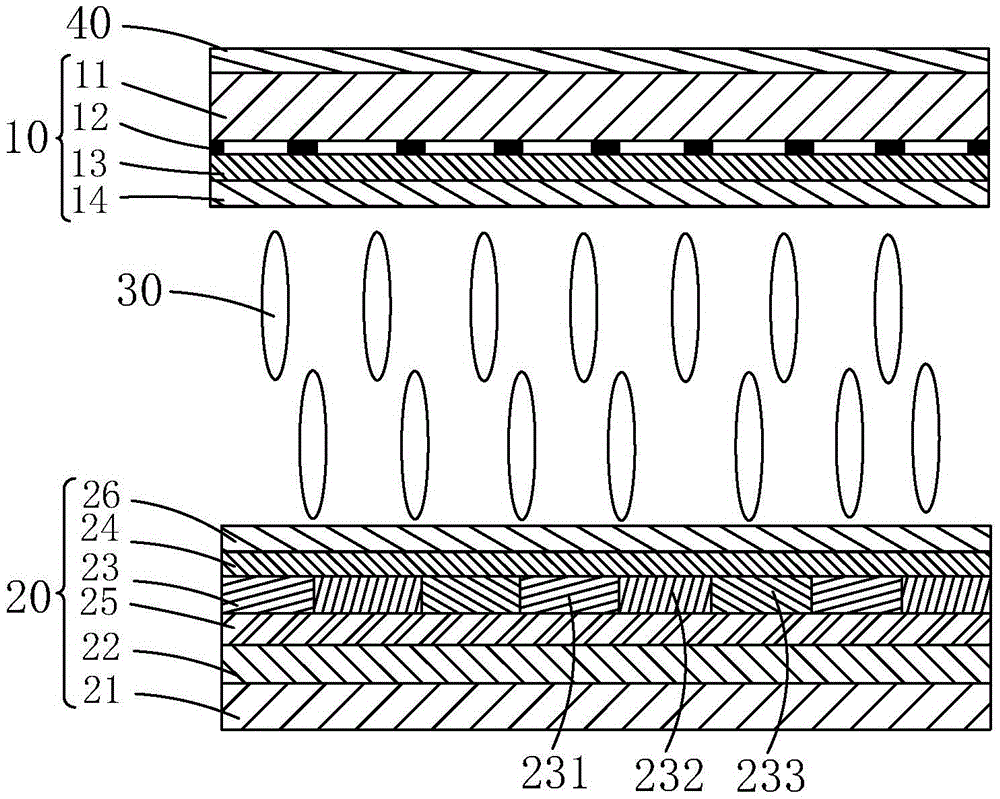

[0042] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

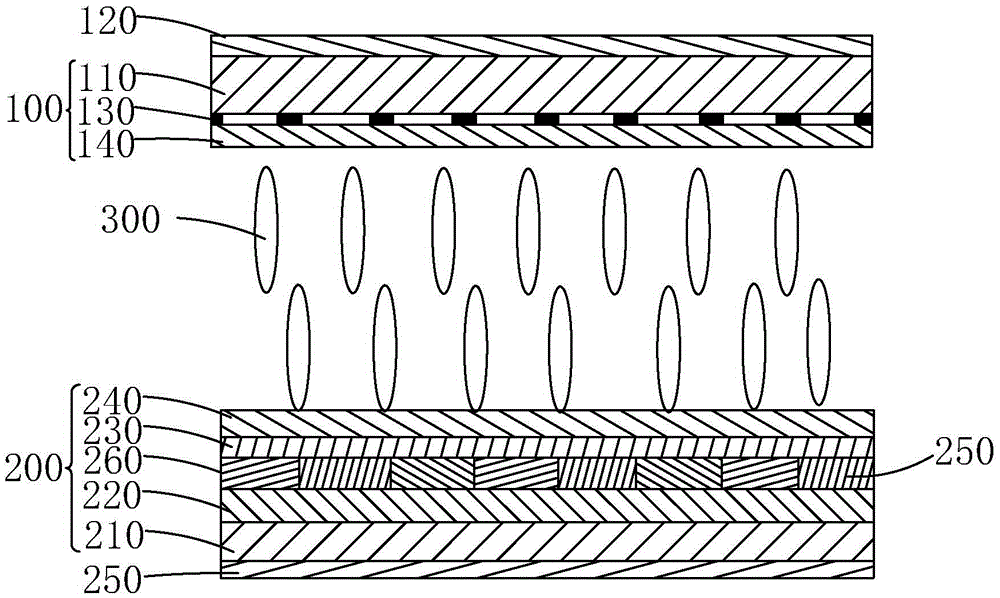

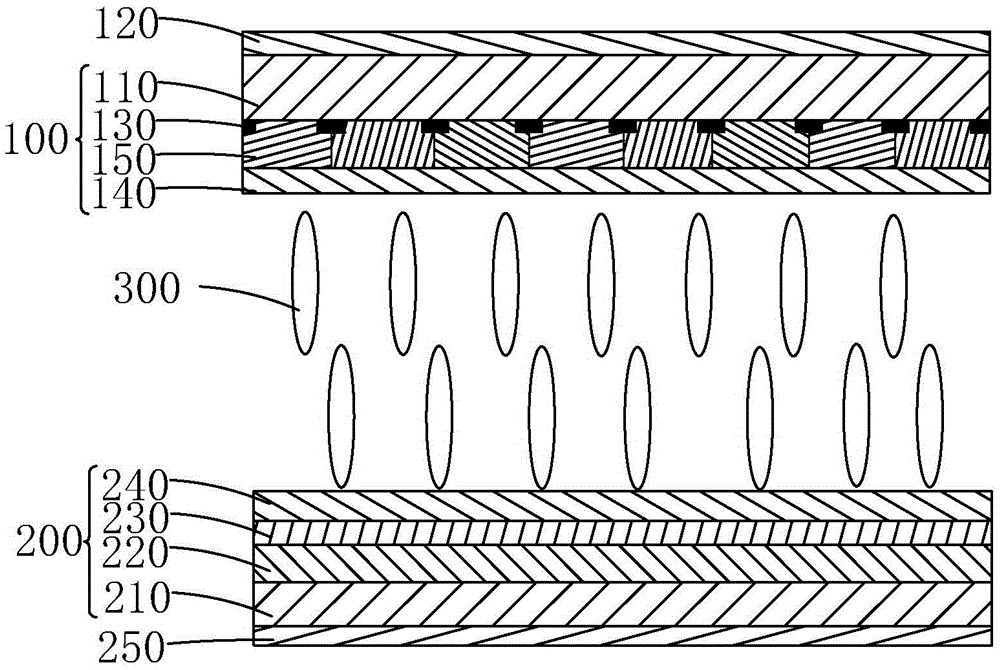

[0043] See image 3 , Is a schematic cross-sectional view of the first embodiment of the liquid crystal display panel of the present invention. This embodiment is a COA (Color Filter on Array) structure liquid crystal display panel, which includes an upper substrate 10 and a lower substrate 20 disposed oppositely, and the upper and lower substrates 10 , 20 between the liquid crystal layer 30, and the upper polarizer 40 arranged above the upper substrate 10;

[0044] The upper substrate 10 includes a first substrate 11, a black matrix 12 arranged on the side of the first substrate 11 close to the liquid crystal layer 30, a common electrode layer 13 arranged on the black matrix 12, and a common electrode layer 13 arranged on the common The first alignment film 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com