Deicing robot for double spacing-variable electric wires

A variable-spacing, robotic technology, applied in electrical components, cable installation, overhead line/cable equipment, etc., can solve problems such as difficulty in controlling the knocking force, damage to the wire cortex, and inability to use different-spacing wires for deicing operations, etc. Reduced vibration and shaking, protection from damage, smooth de-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to express the technical means, objectives and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

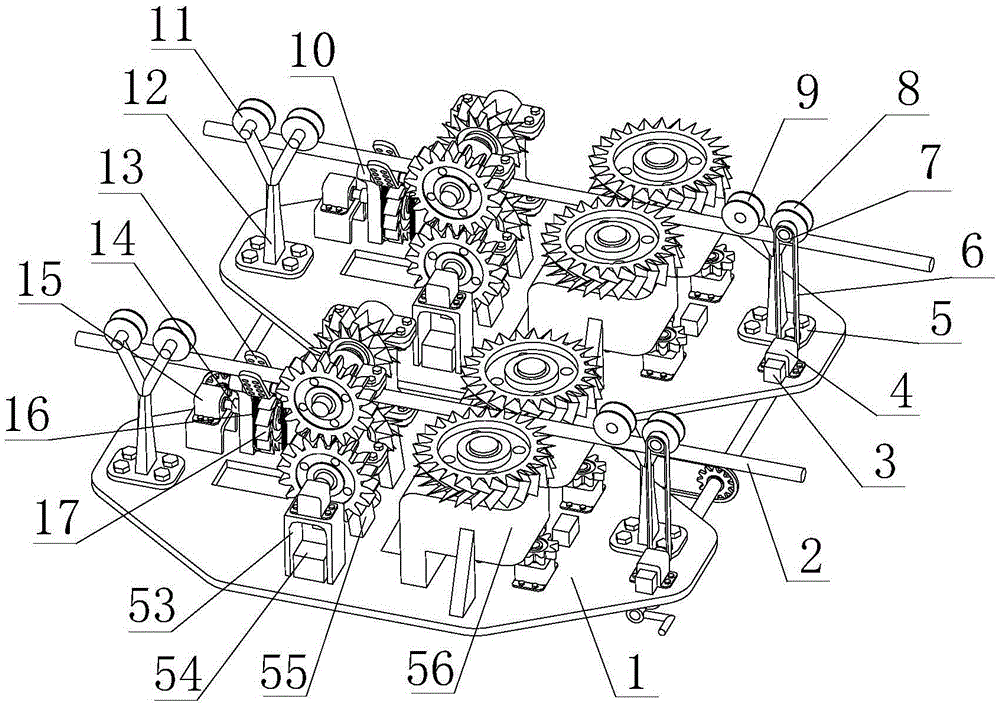

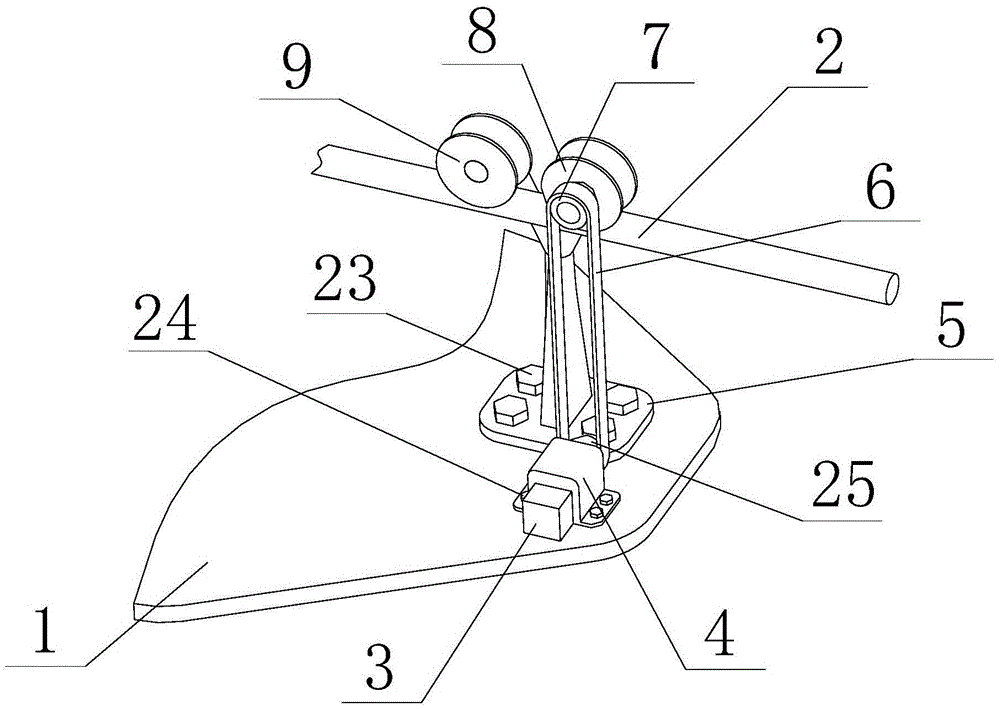

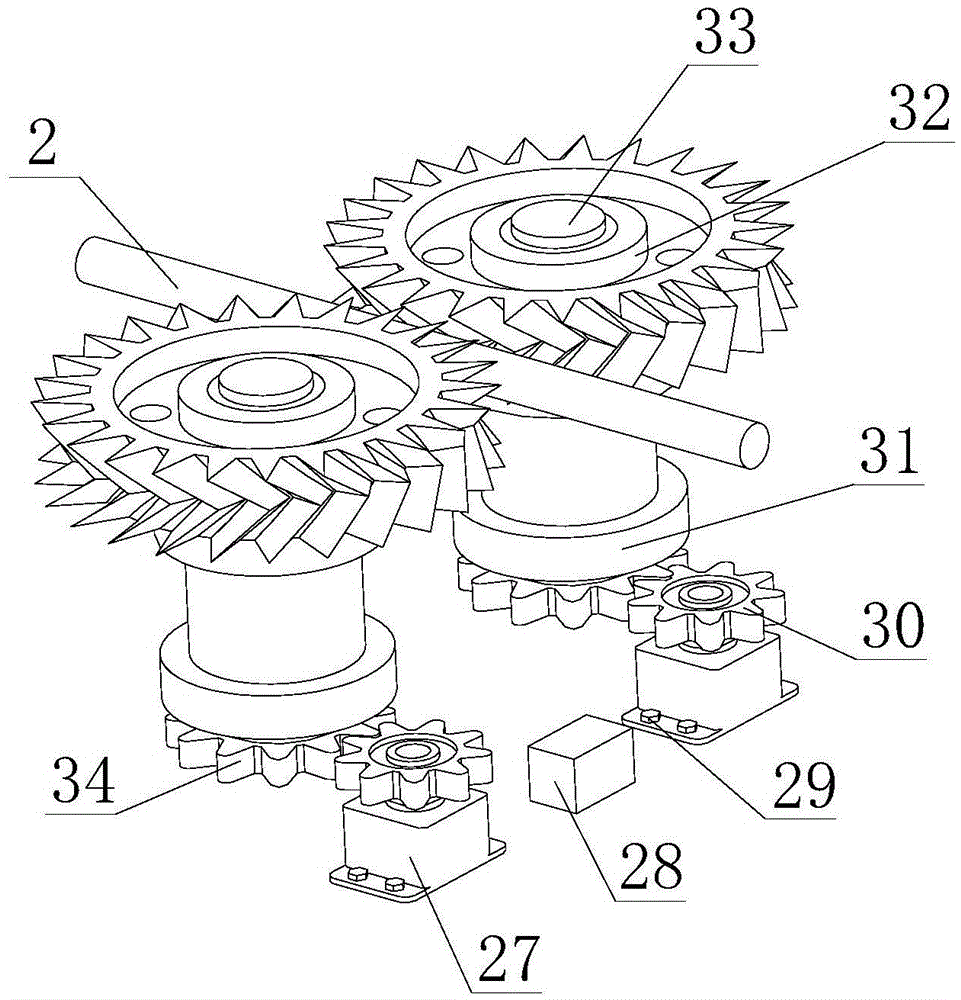

[0032] See attached figure 1 , because the main structure of the device is a symmetrical structure, that is, the structures on the two bottom plates in the device are the same, and the two bottom plates are connected by a spacing adjustment mechanism, so the following half of the structure of the device is used as an example for illustration. as attached Figure 1-11 Shown, a kind of duplex variable-pitch electric wire deicing robot comprises base plate 1, front guide walking mechanism (by power supply one 3, first motor 4, toothed pulley two 25, toothed belt 6, toothed pulley on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com