Starting structure, starting method and starting device for brushless double-feed motor

A technology of starting device and motor, applied in the direction of starting device, etc., can solve the problems of high cost, many supporting equipment for motors, and excessive starting current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the following examples.

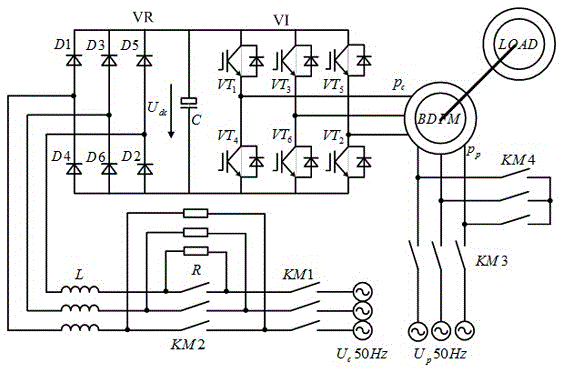

[0026] A starting structure of a brushless doubly-fed motor in this embodiment belongs to an asynchronous starting structure, such as figure 1 As shown, it includes a frequency converter, and the frequency converter includes a first contactor KM1, a soft-start resistor R, a soft-start second contactor KM2, an input reactor L and a three-phase full-bridge uncontrolled rectifier circuit VR connected to the rectifier circuit The bus capacitor C at the output end of the bus capacitor C, the three-phase full-bridge inverter circuit VI connected to the output end of the bus capacitor C, the output end of the three-phase full-bridge inverter circuit VI is connected to the control winding P of the brushless doubly-fed motor C .

[0027] The three-phase AC power supply is sequentially connected to the first contactor KM1, the second soft-start contactor KM2, the input reactor L and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com