Production technology for delaying browning of shredded squid

A production process and a technology for shredded squid, which are applied in the field of production technology for delaying the browning of shredded squid products, can solve problems such as easy browning of shredded squid products, and achieve the effects of improving sensory quality, delaying the degree of browning, and improving acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

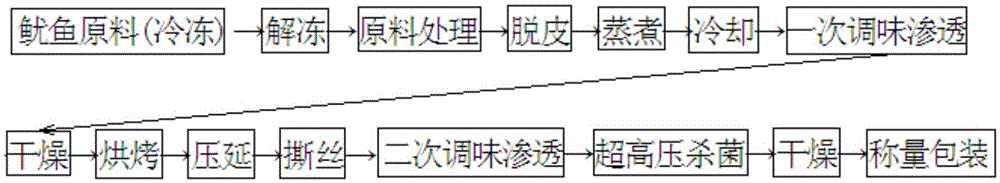

[0024] see figure 1 Shown, a kind of production technique that the present invention delays squid shredded product browning, production technique comprises the steps:

[0025] 1. Thawing and raw material processing: Thaw the frozen squid in flowing water at 10-15°C. When the fish body is in a semi-thawed state, perform raw material processing; remove the head, viscera, cartilage, etc., and perform peeling treatment.

[0026] 2. Cooking and cooling: Steam the squid slices after peeling immediately, the temperature is controlled at 85-90°C, and the time is 3-5min. Bring to room temperature.

[0027] 3. One-time seasoning penetration: add seasoning, stir well, so that the seasoning is evenly distributed on the fish and continuously melted, and then placed in an environment around 10°C for 12 hours; the seasoning consists of 2.7 parts by weight of NaCl, 7 parts of Sucrose and 0.35 parts of monosodium glutamate.

[0028] 4. Drying: Dry the squid slices with hot air, the drying t...

Embodiment 2

[0035] The production technology of embodiment 2 and embodiment 1 is basically the same, and its difference is that, after step 7 of embodiment 1, increase squid shreds and carry out ultra-high pressure treatment, ultra-high pressure pressure is 300MPa, and processing time 10min; Adopt this ultra-high pressure treatment After the shredded squid tastes no difference with the shredded squid produced in Example 1, and after 9 months of storage and storage of 6 months in Example 1, the whiteness is the same, and the senses are good.

Embodiment 3

[0037] The production process of embodiment 3 and embodiment 1 is basically the same, and its difference is that, after step 7 of embodiment 1, the ultrahigh pressure treatment is carried out to squid shreds, the ultrahigh pressure pressure is 500MPa, and the treatment time is 20min; adopt this ultrahigh pressure treatment The shredded squid after the taste is slightly worse than the shredded squid produced in Example 1, but after 15 months of storage and in Example 1, the whiteness of 6 months is the same, and the senses are good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com