Roller type dust removing device

A dust removal device and a drum-type technology, which are applied in cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as no increase in production efficiency, unstable air pump pressure, and decreased production efficiency, so as to reduce errors. The effect of reducing the risk of judgment, reducing running time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

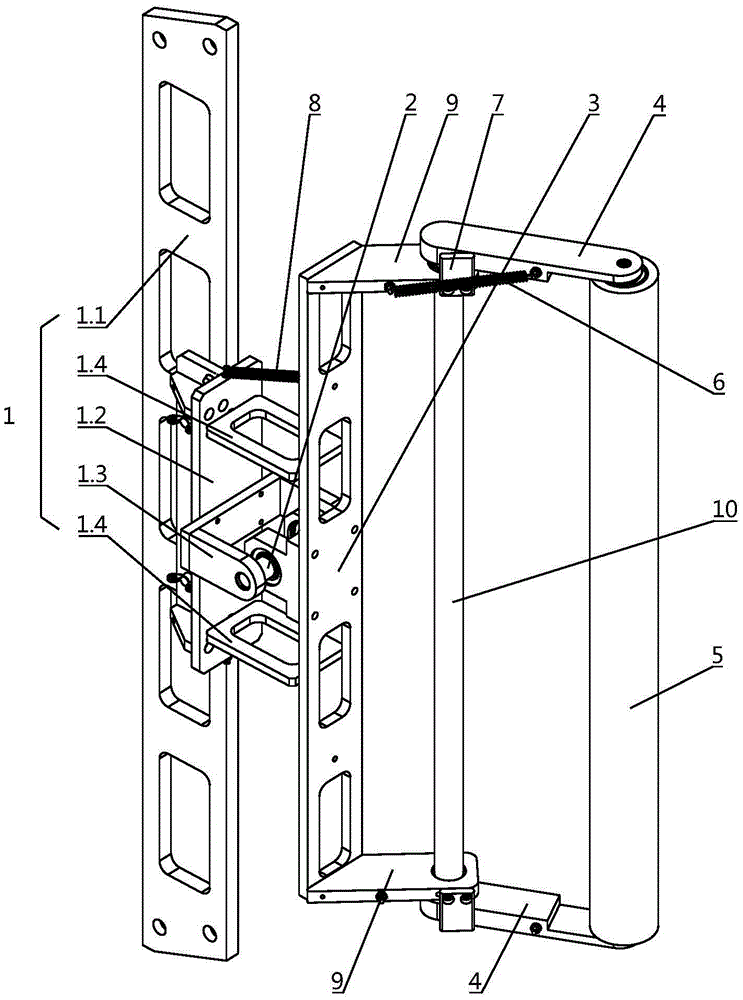

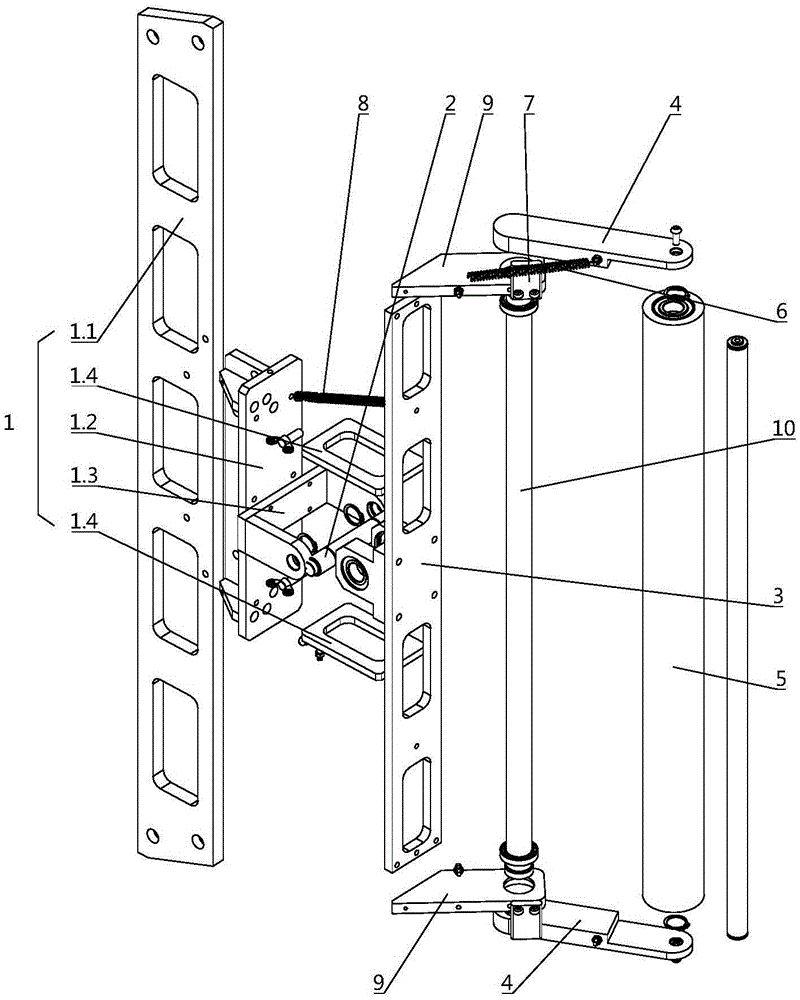

[0018] pass below Figure 1 ~ Figure 2 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0019] Such as figure 1 with figure 2 The drum-type dust removal device shown includes a mounting frame 1, and the mounting frame 1 is rotatably connected to the middle part of a mounting plate 3 through a horizontal rotating shaft 2. The length direction of the mounting plate 3 is perpendicular to the horizontal rotating shaft 2, and the mounting plate 3 The two ends of the length direction are all rotatably connected to a roller mounting seat 4, and one end of the roller mounting seat 4 is connected to the end of the mounting plate 3 and rotates on an axis parallel to the length direction of the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com