Lost Foam Mold for Motor Housing with Insert Quick Change Structure

A technology of motor casing and lost foam, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of increasing production costs and labor intensity, troublesome interchange, high cost, etc., and achieves good product consistency, The mold is easy to operate and the effect of white mold forming is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

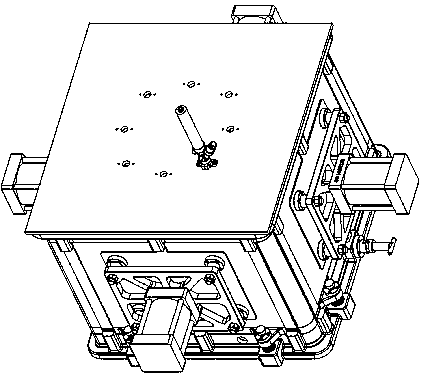

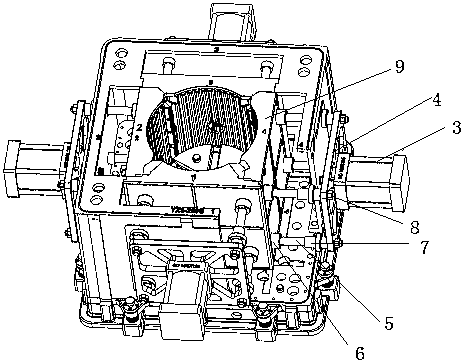

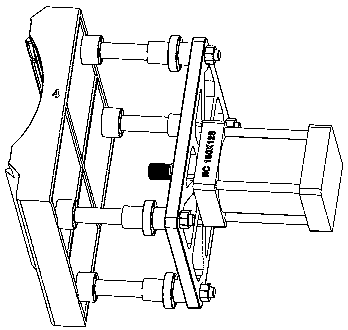

[0028] The present invention is described in conjunction with picture and specific embodiment:

[0029] Such as figure 1 , Figure 4 As shown, a motor shell lost foam mold with insert quick change structure, combined with Figure 10 , Figure 11 , the purpose of the quick-change structure of the motor case is to produce the motor case horizontal base 1 and the motor case vertical base 2 in the same mold; the motor case lost foam mold includes an upper die 12 and lower mold 16; combine Figure 9 , the upper mold 12 includes an upper mold core 28, an upper mold air frame 32 and an upper mold sealing plate 11; the upper end surface of the upper mold air frame 32 is closed by the upper mold sealing plate 11; the upper mold sealing plate is installed Automatic material gun 10 is installed on 11, and the both sides of patrix 12 respectively make patrix sprue 13 respectively two; Described patrix core 28 is inlaid on patrix air frame 32 by spring and screw 29, and described patri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com