Metal tube drilling machine capable of adjusting space

A technology for adjusting spacing and metal tubes, which is applied to metal processing machinery parts, boring/drilling, metal processing equipment, etc., can solve the problems of rough processing, expensive purchase, waste of financial and material resources, etc., and achieve high processing accuracy and convenient use , the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

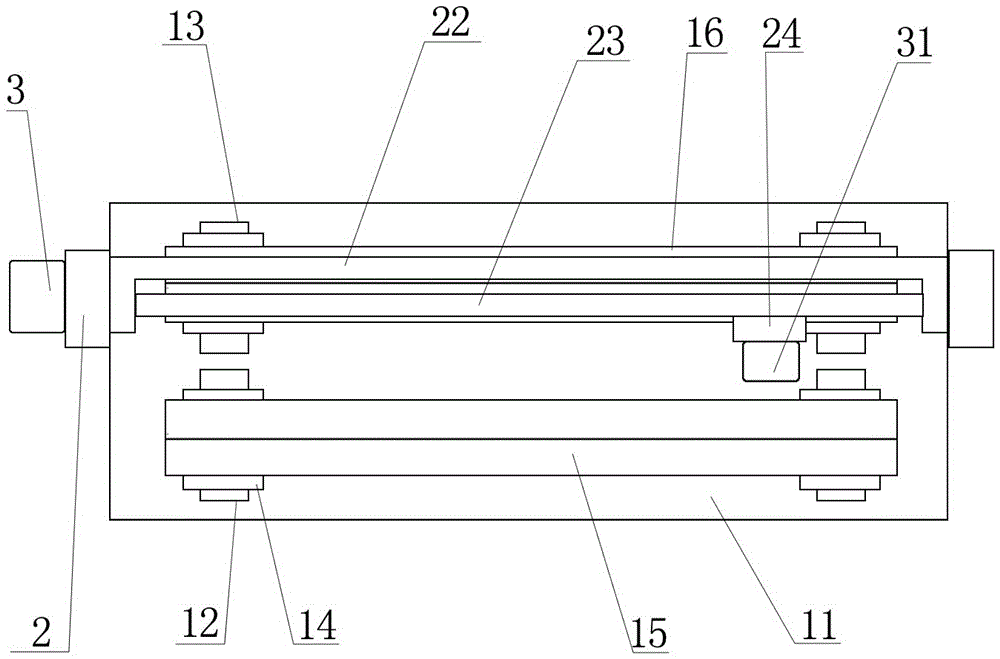

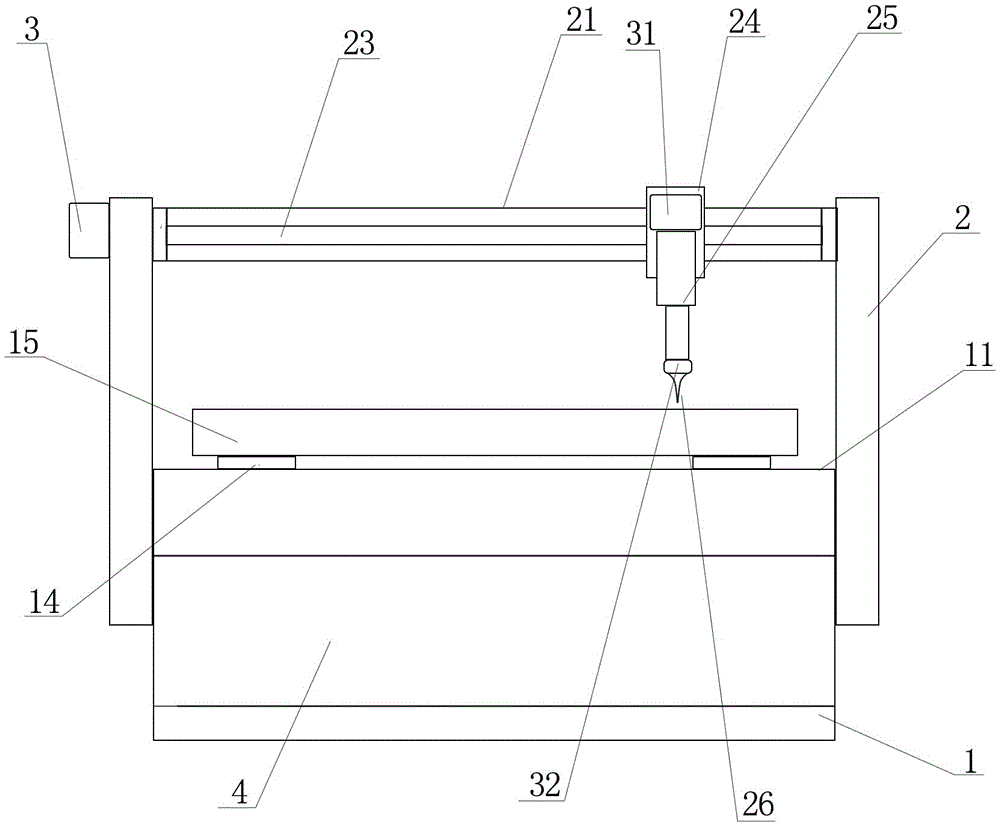

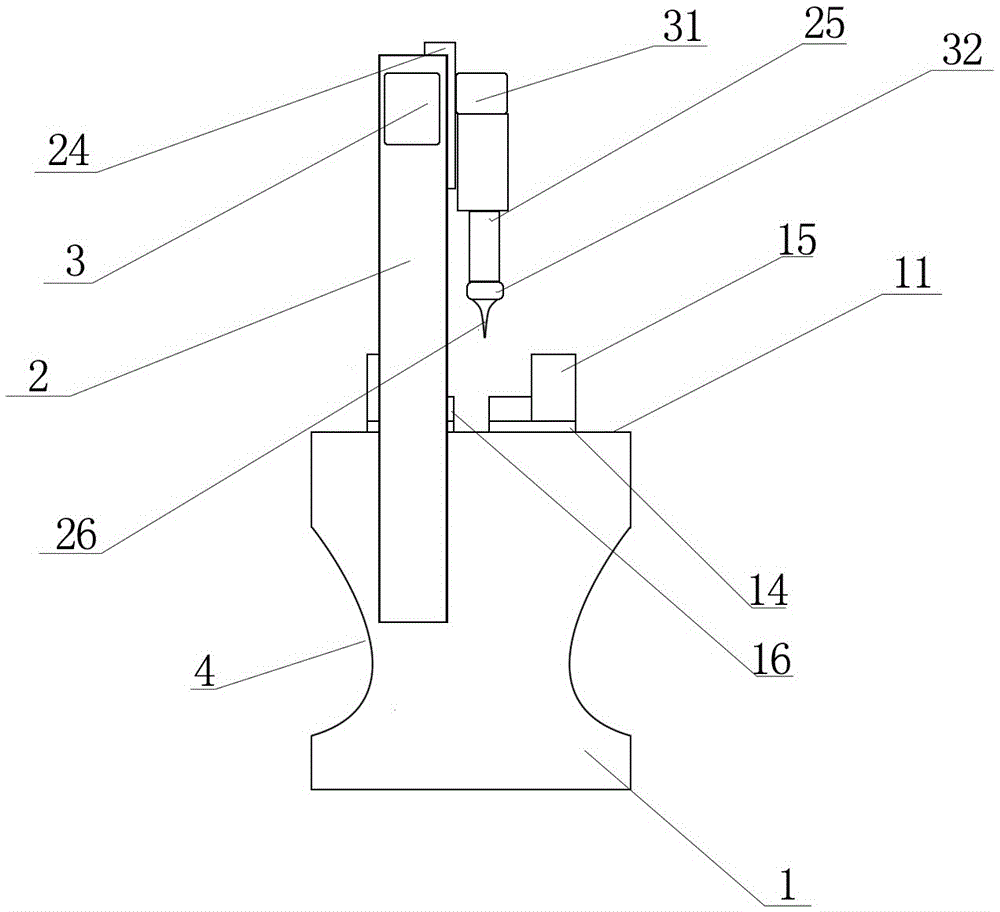

[0015] Such as Figure 1 to Figure 3 As shown, a metal pipe drilling machine with adjustable spacing of the present invention includes a support 1, which is characterized in that: the top of the support 1 is a horizontal plane 11, and two sides of the plane 11 are correspondingly provided with two The first chute 12, the first chute 12 is provided with the second chute 13 as a mirror image, the first chute 12 and the second chute 13 are correspondingly provided with a slide plate 14 that can slide, and the first chute 12 The sliding plate 14 is provided with an L-shaped first metal pipe fixing seat 15, the sliding plate 14 on the second chute 13 is provided with an L-shaped second metal pipe fixing seat 16, and the two sides of the support 1 are respectively vertically provided with a Fixed rods, two fixed rods are all set correspondingly, a spiral cross bar is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com