Deep hole finish machining method of motor casing of nuclear main pump

A motor casing and main pump technology, applied in the field of processing tooling, can solve problems such as difficulty in ensuring dimensional accuracy and shape accuracy, large diameter, and inability to manufacture motor casing products, and achieve convenient and economical processing, high processing efficiency, The effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

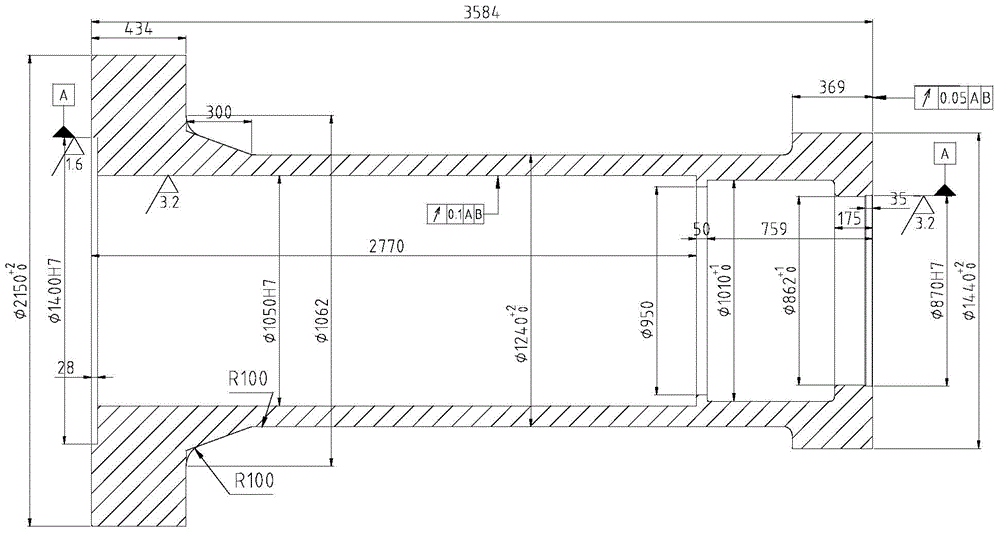

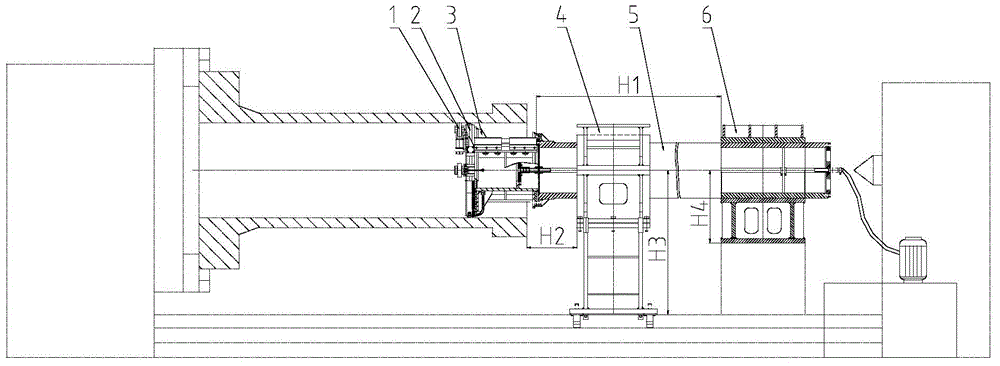

[0040] Such as figure 2 , image 3 As shown, the deep hole finishing method of the nuclear power main pump motor housing of the present invention adopts the deep hole finishing tooling of the nuclear power main pump motor housing to finish the deep hole of the nuclear power main pump motor housing, so that the depth of the deep hole The inner diameter is Φ1050H7( +0.105 0 )mm, the hole depth is 2770mm;

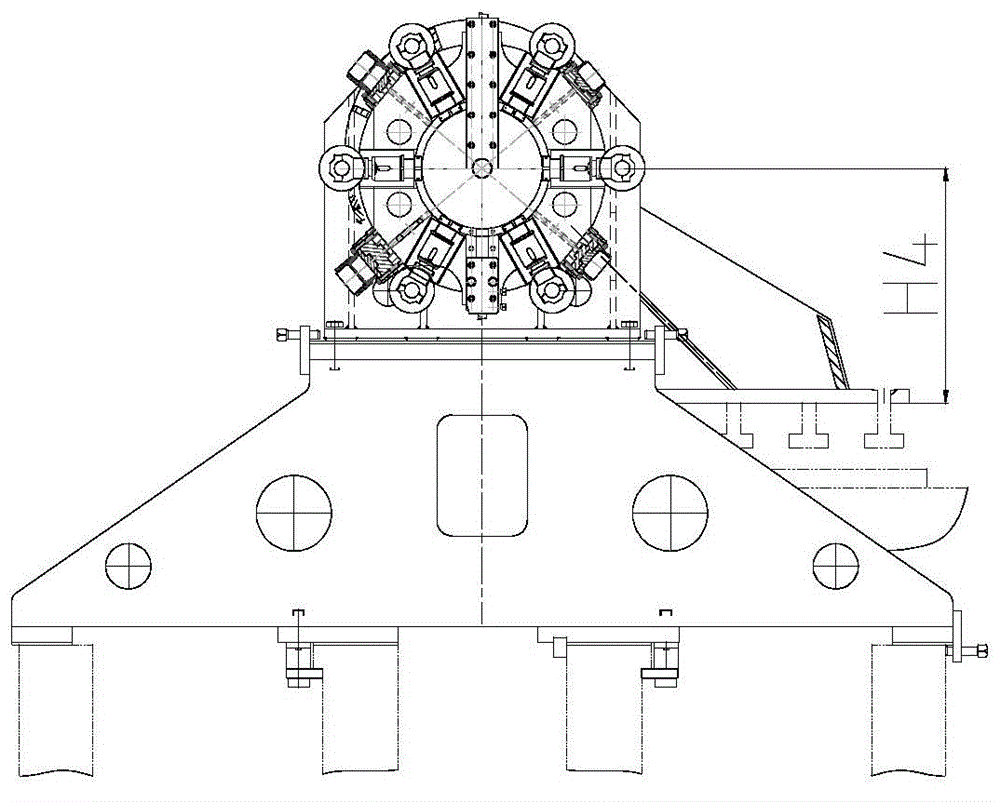

[0041] The deep hole finishing tooling of the nuclear power main pump motor casing of the present invention includes a rear support frame 6, the rear support frame 6 supports the tail end of the boring bar 5, and the middle part of the boring bar 5 is supported by the front support frame 4;

[0042] In order to enable the boring tool to carry out boring processing along the processed hole, the boring bar 5 is hollow, and the inner hole of the boring bar 5 is used to add high-pressure coolant to wash away chips and cool and lubricate;

[0043] The front end of the boring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com