Vacuum mechanism of rubber plate vulcanization machine

A flat vulcanizing machine and vacuum technology, applied in the field of vacuum mechanism, can solve the problems of poor surface quality of finished products, complicated processing and installation, long vulcanization time of products, etc. And the effect of easy maintenance and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

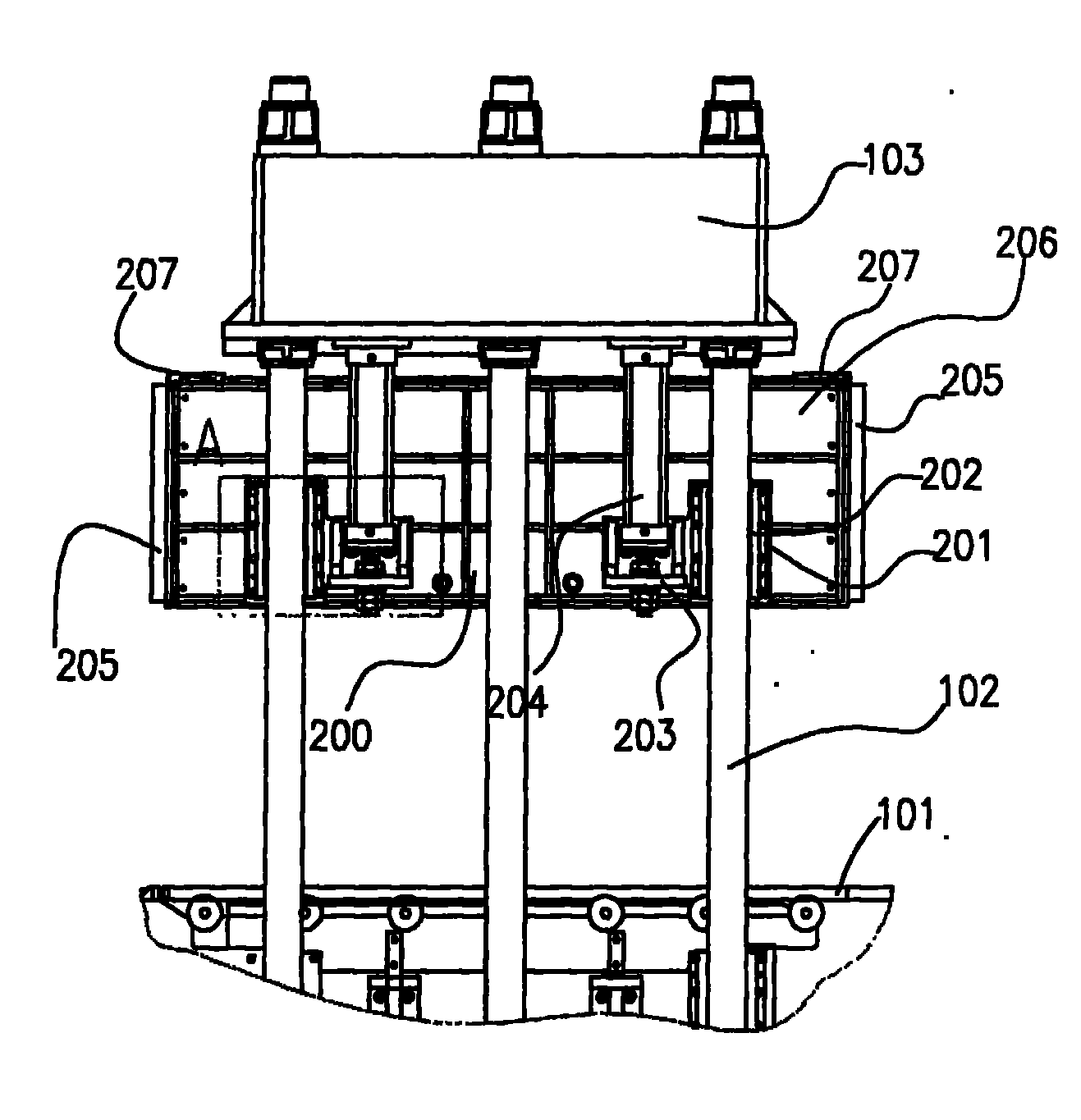

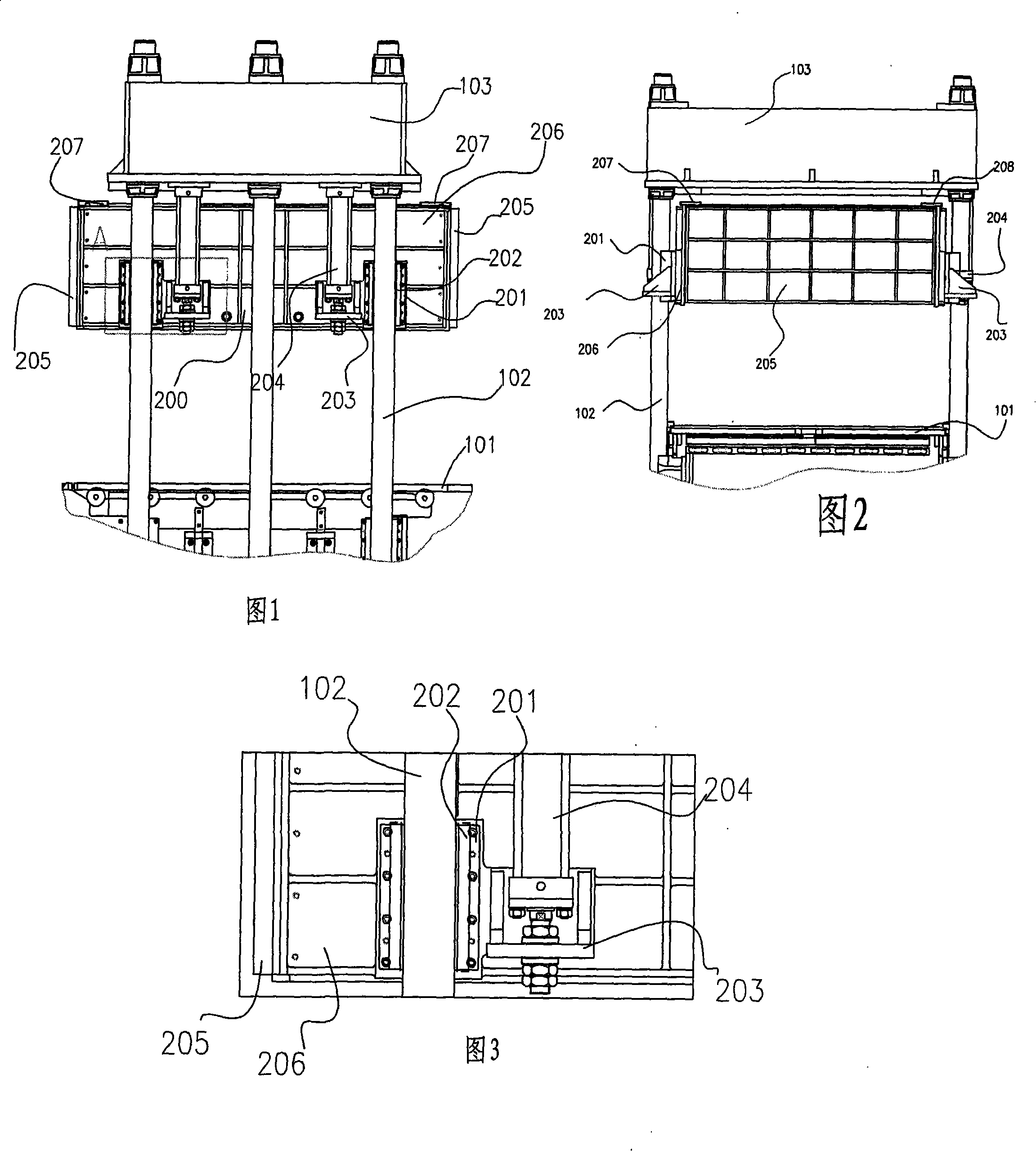

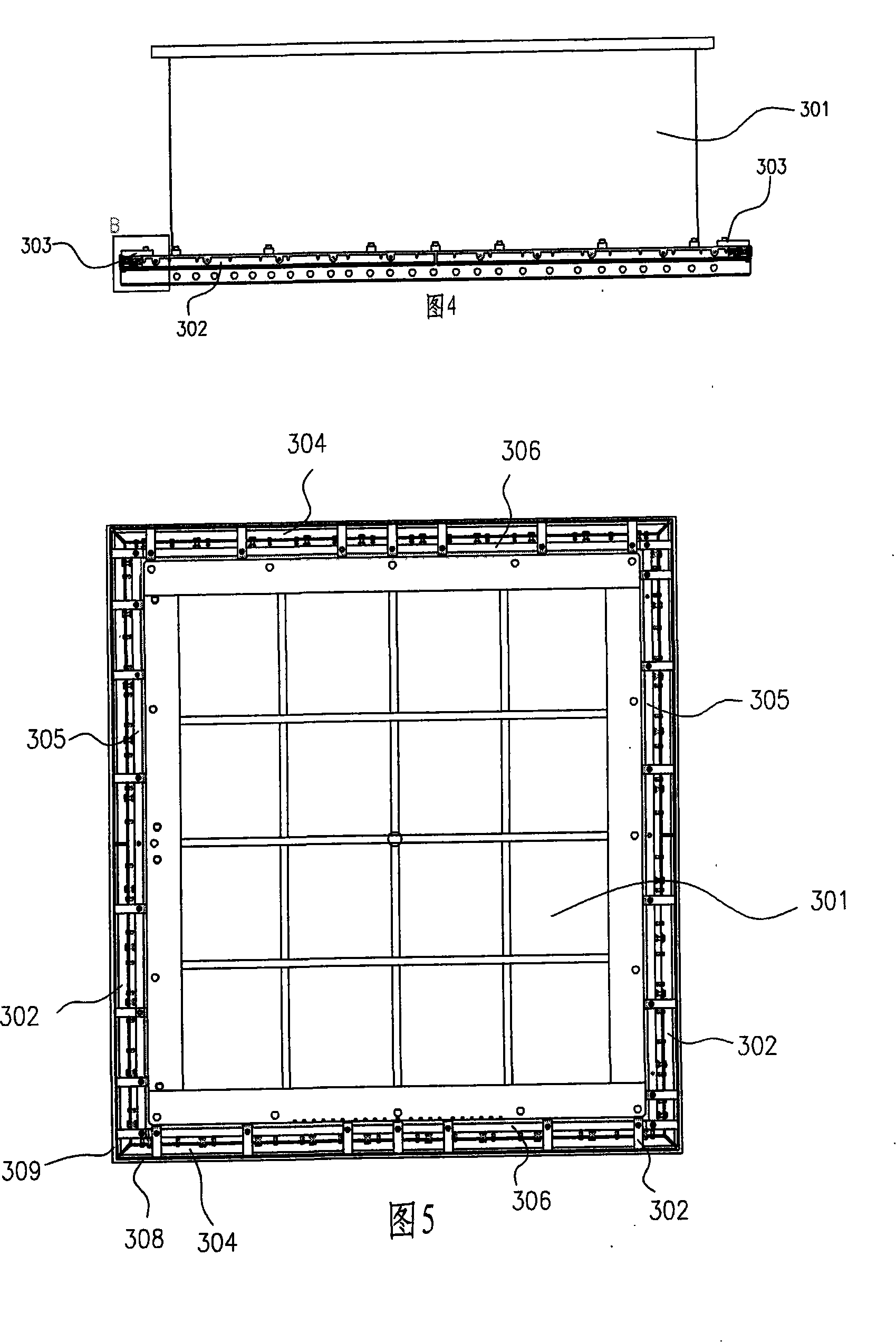

[0023] The structure of the present invention is shown in Fig. 1 to Fig. 9 . Numbers in the figure, sliding plate 101, pillar 102, top seat 103, vacuum cover 200, vacuum cover copper lining seat 201, copper lining 202, vacuum cover oil cylinder fixing frame 203, vacuum cover oil cylinder 204, vacuum cover front and rear walls 205, vacuum cover Left and right walls 206, left right-angle reinforcing plate 207, right right-angle reinforcing plate 208, sealing oil-resistant strip 209, sliding column 301, rubber strip left and right pressure plate 302, pressure plate 303, rubber strip front and rear pressure plate 304, left and right fixing blocks 305, front and rear fixing plates 306, vacuum cover leak-proof rubber strip 307, front and rear slider 308, left and right slider 309, square aluminum extruded type 310, T-shaped screw 311, T-shaped screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com