Feeding system and method of steel rail profile modeling grinder

A feed system and grinding machine technology, which is applied to the parts of grinding machine tools, grinding machines, grinding driving devices, etc., can solve the problems of poor recognition ability of motion state and difficult adjustment of grinding precision, and achieve the effect of improving control precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An embodiment of a feed motion control method for a rail profiling grinder provided by the present invention controls the grinding accuracy by controlling the feed motion of a grinding wheel, improves operating efficiency, and avoids construction accidents. The method provided comprises the steps of:

[0031] Setting the positioning reference plane of the grinding wheel feed, the positioning reference plane can be any position of the grinding wheel working surface on the feed movement track;

[0032] Set the operation mode of the grinding wheel, which can be a restricted mode or an unrestricted mode; the feed movement of the grinding wheel is restricted or unrestricted at the positioning reference plane;

[0033] Setting the single feed displacement of the grinding wheel, the single feed displacement of the grinding wheel is the single feed of the grinding wheel relative to the object to be ground;

[0034] Record the operating time of the grinding wheel.

[0035] Amo...

Embodiment 2

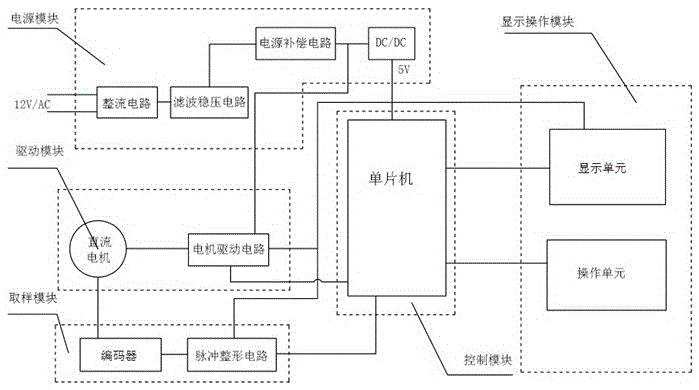

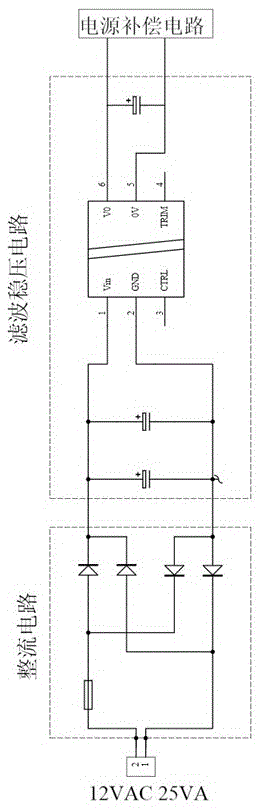

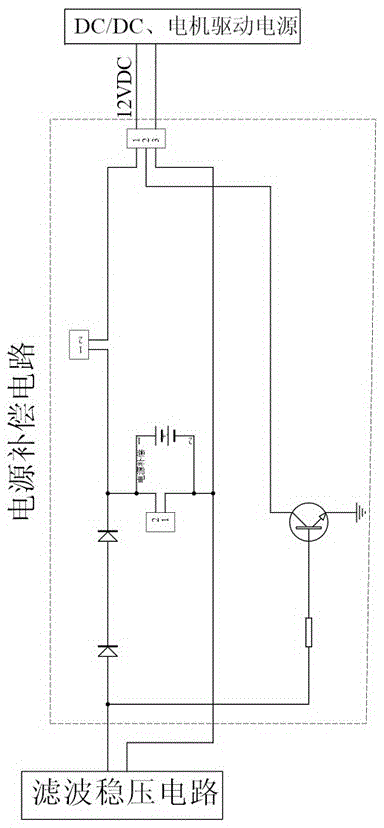

[0042] An embodiment of the feeding system of a rail profiling grinding machine provided by the present invention, as attached figure 1As shown, it includes a feed system of a rail profiling grinding machine. The feed system grinds the rail by controlling the feed displacement of the grinding wheel. The feed system includes a power module, a control module, a drive module, a sampling module and The display operation module, the power module receives the AC voltage provided by the outside, and supplies the DC voltage to the drive module, the control module, the sampling module and the display operation module, and the power module is respectively connected with the drive module, the control module, the sampling module and the display operation module; the drive The module provides mechanical power for the feed movement of the grinding wheel. The drive module is connected to the sampling module, power module and control module respectively; the sampling module obtains the motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com