Railway vehicle frame and bogie

A rail vehicle and bogie technology, which is applied in the field of railway locomotive vehicle structure design, can solve the problems of not involving the integrated installation of brake units, large space occupied by the bogie area, and high installation position of secondary springs, so as to increase the interior space of the vehicle, Good structural performance, the effect of reducing the overall and local height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

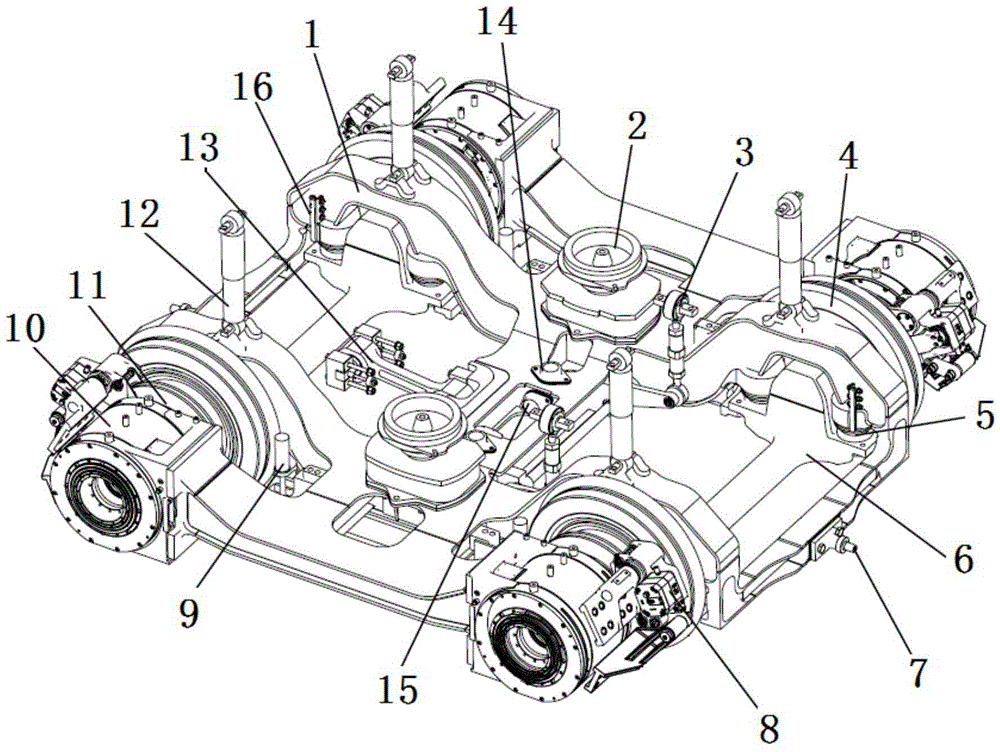

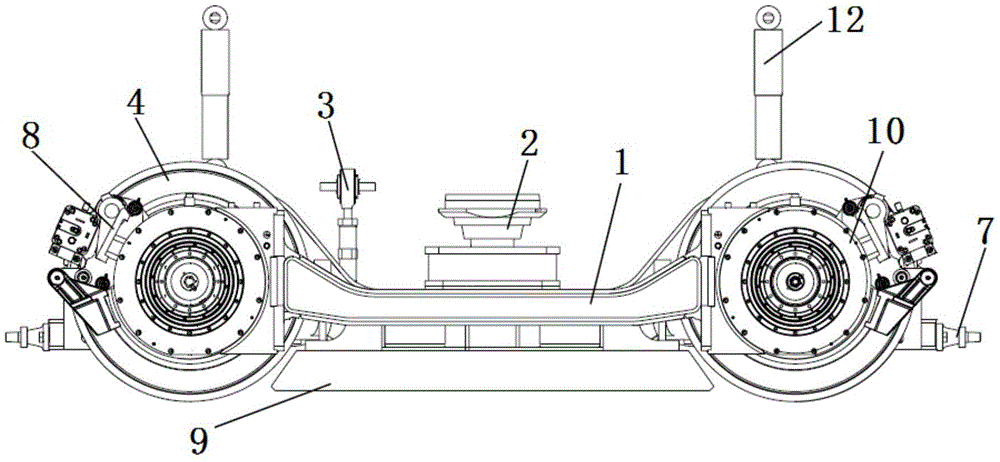

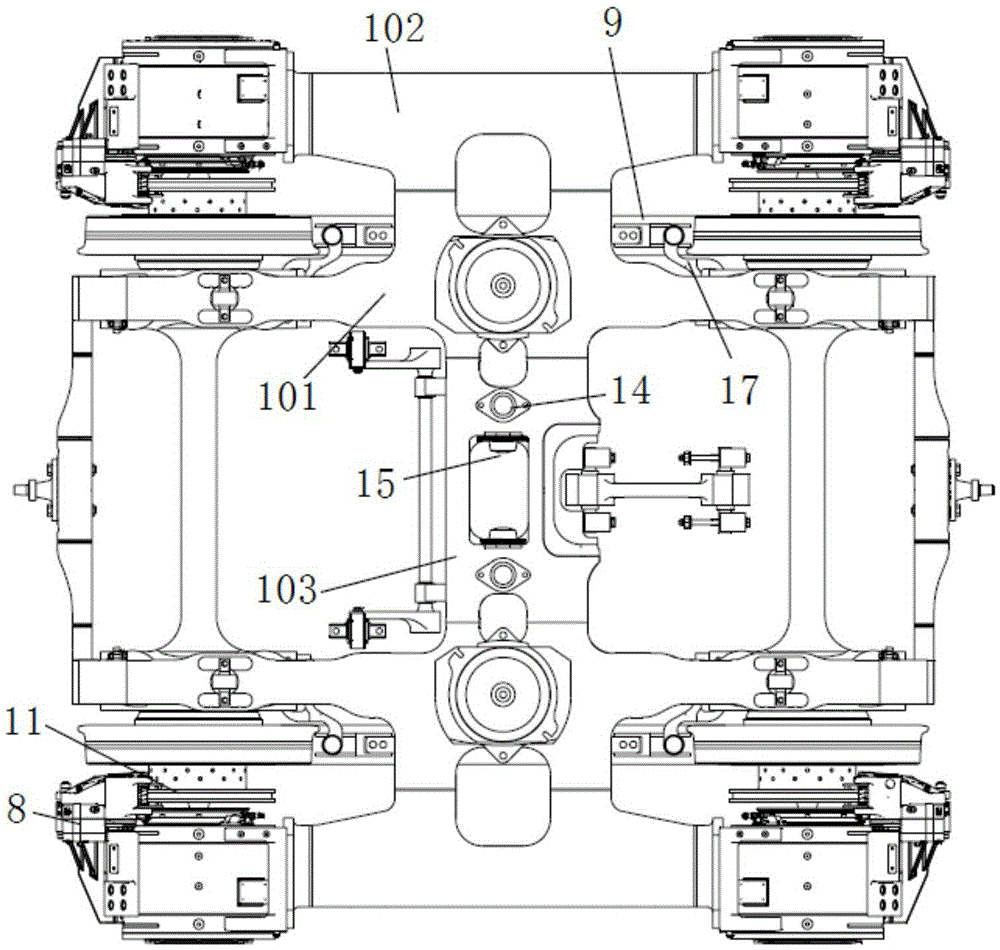

[0031] A rail vehicle bogie driven directly by wheel-side permanent magnet motors, such as Figure 1-4 As shown, the bogie mainly includes frame 1, traction device 13, independent wheels 4, axle bridge 6, primary suspension device 5, secondary suspension device 2, hydraulic braking device 8, magnetic rail brake 9 and other parts.

[0032] The bogie adopts a layered box-type welded frame, and its specific structure is that the motor suspension beam 102 of the frame 1 is a cantilever structure, the height of the upper cover plate of the motor suspension beam is higher than that of the crossbeam 103, and the side rails pass between the cover plates. The upper cover plate of the beam 101 is connected to reduce the stress concentration of the frame and improve the stress condition of the frame. The layered structure can meet the space requirements of the magnetic track brake 9 and allow the vertical plate structure of the cantilever structure of the motor suspension beam to have a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com