Ship wall connector for oil boom and quick connector for oil boom

A technology for connectors and oil booms, which is applied in the field of oil boom wall connectors, oil boom quick connectors, and ships with ferromagnetic walls, which can solve the problems of long deployment time, unfavorable oil spill recovery, and manpower Problems such as large material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

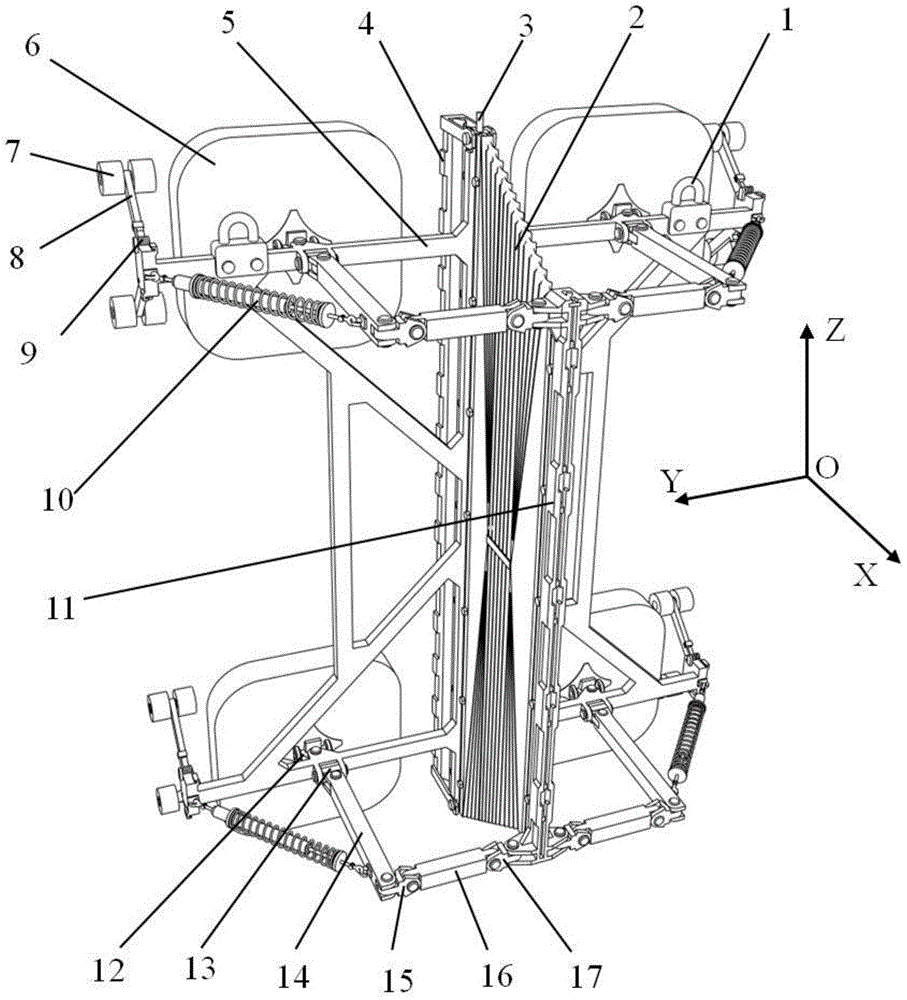

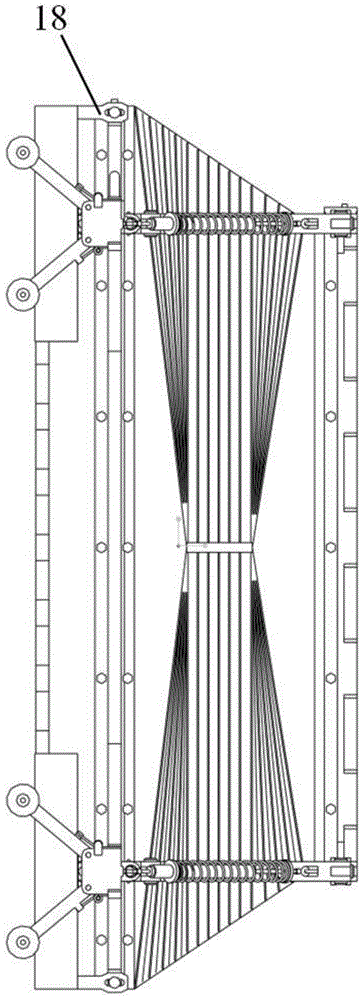

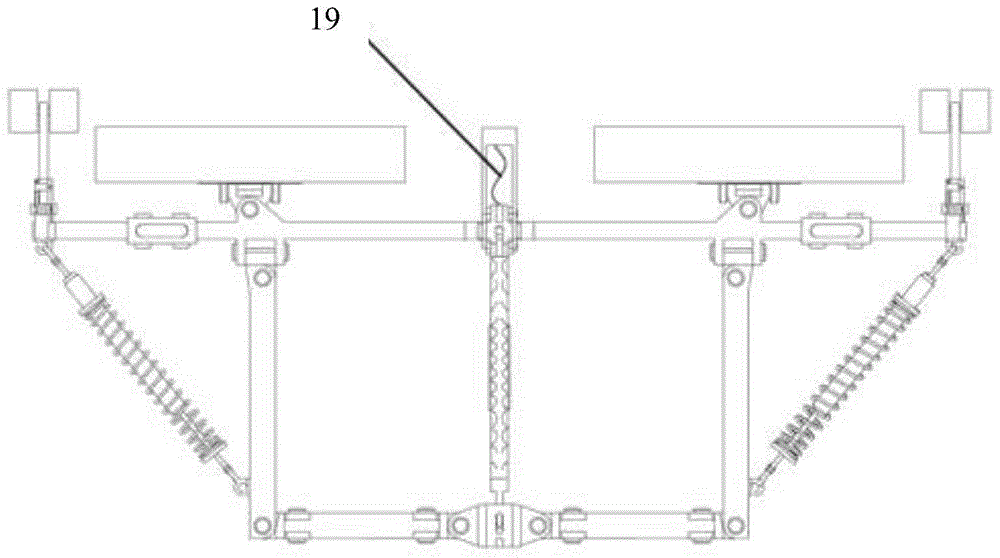

[0023] Such as figure 1As shown, the main body of the ship wall connector consists of a lifting ring 1, a partially folded tarpaulin with a support rod 2, a cable joint 3, a long rubber body inlaid with a permanent magnet block 4, a main bracket 5, an electromagnetic adsorption module 6, and a magnetic wheel 7. Suspension link 8, torsion spring 9, linear tension spring damper 10, sub-bracket 11, first short link 12, second short link 13, first long link 14, third short link 15, the second long connecting rod 16, the fourth short connecting rod 17 and other components are formed. Two of the lifting rings 1 are fixed on the main bracket 5 . The partially folded tarpaulin 2 with support rods is trapezoidal as a whole, one end of its trapezoidal long side is fixed on the main bracket 5, and one end of its trapezoidal short side is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com