Ventilating plastic box

A plastic box and air-permeable technology, which is applied to building components, floor slabs, buildings, etc., can solve the problems of unguaranteed concrete pouring quality at the bottom of the slab, low stiffness of filling materials, and high buoyancy of filling materials, achieving good economy and applicability , Overcoming the effects of small stiffness and large span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is realized in the following manner:

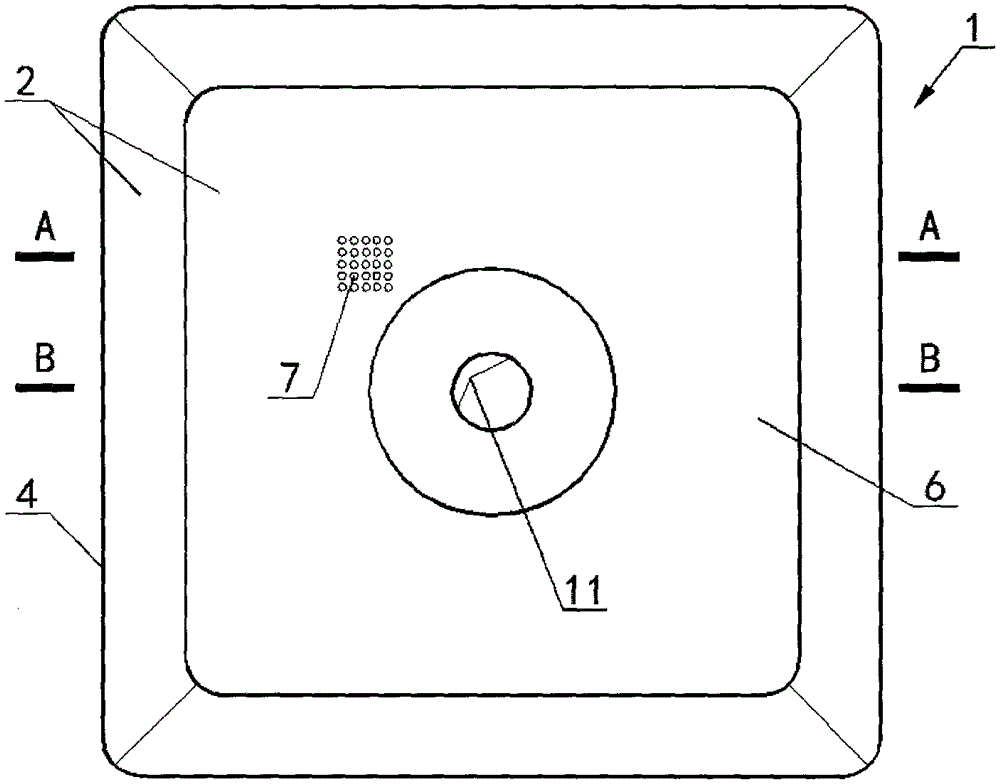

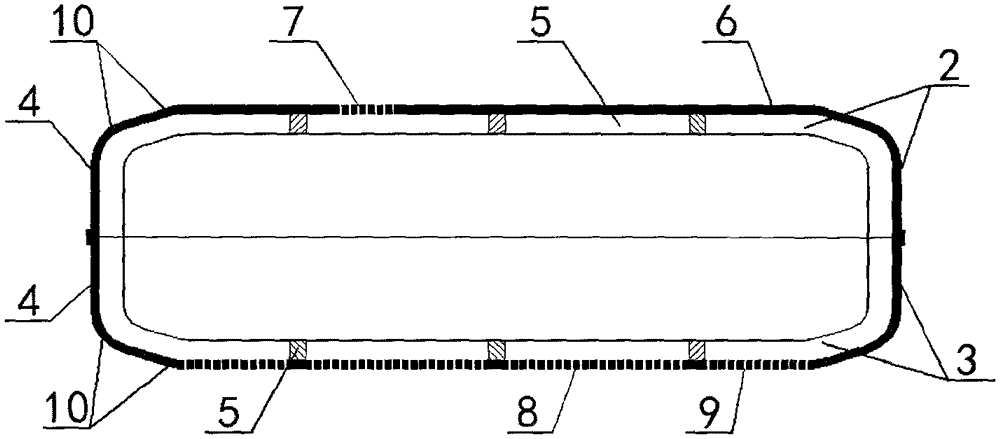

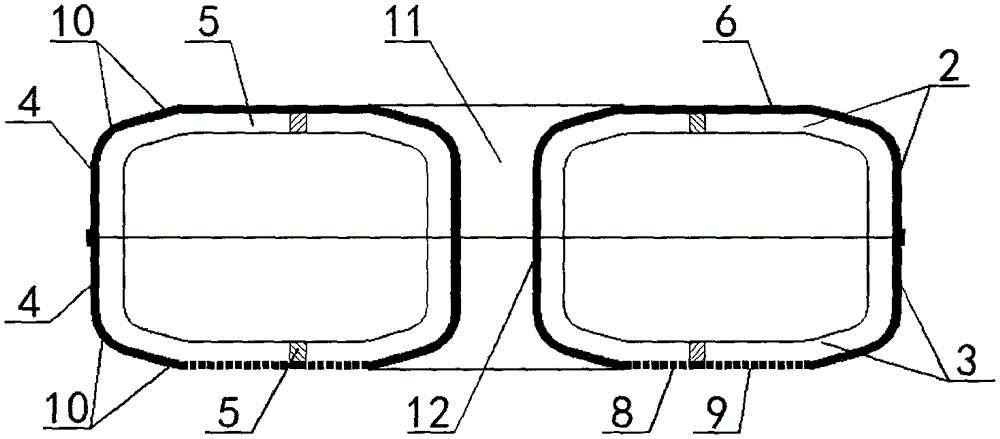

[0031] exist Figure 1-Figure 5 In the shown embodiment, a kind of air-permeable plastic box, the plane shape of plastic box (1) is rectangle, and the ratio of its long side and short side size is less than or equal to 2, and plastic box comprises upper assembly (2) and lower assembly ( 3), the upper assembly (2) is composed of a frame plate (4), a stiffener (5) and a top cover plate (6). There is one or more vent holes (7) on the top cover plate, and a single vent hole Aperture diameter ≥ 0.5mm and ≤ 8mm, the lower assembly (3) is composed of frame plate (4), stiffener (5) and bottom support plate (8), the bottom support plate is covered with dense ventilation holes (9), a single The diameter of the air hole is ≥4mm and ≤15mm. Stiffeners are uniformly arranged along the inner wall of the frame plate, top cover plate or bottom support plate in the upper and lower components. The upper and lower components are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com