Concrete pumping pipeline cleaning method and device

A technology of concrete pump and cleaning method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of high use cost, pollution, blockage of pumping pipelines, etc., save construction time and cost, and achieve good isolation performance. , the effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment to be described in further detail:

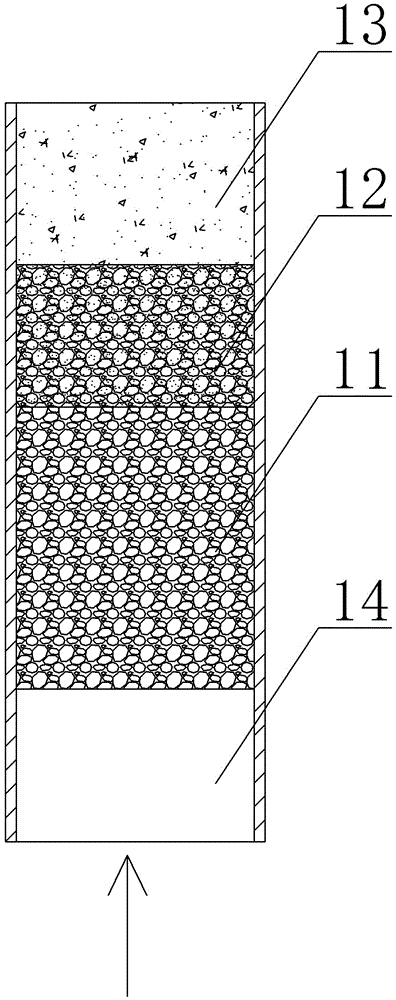

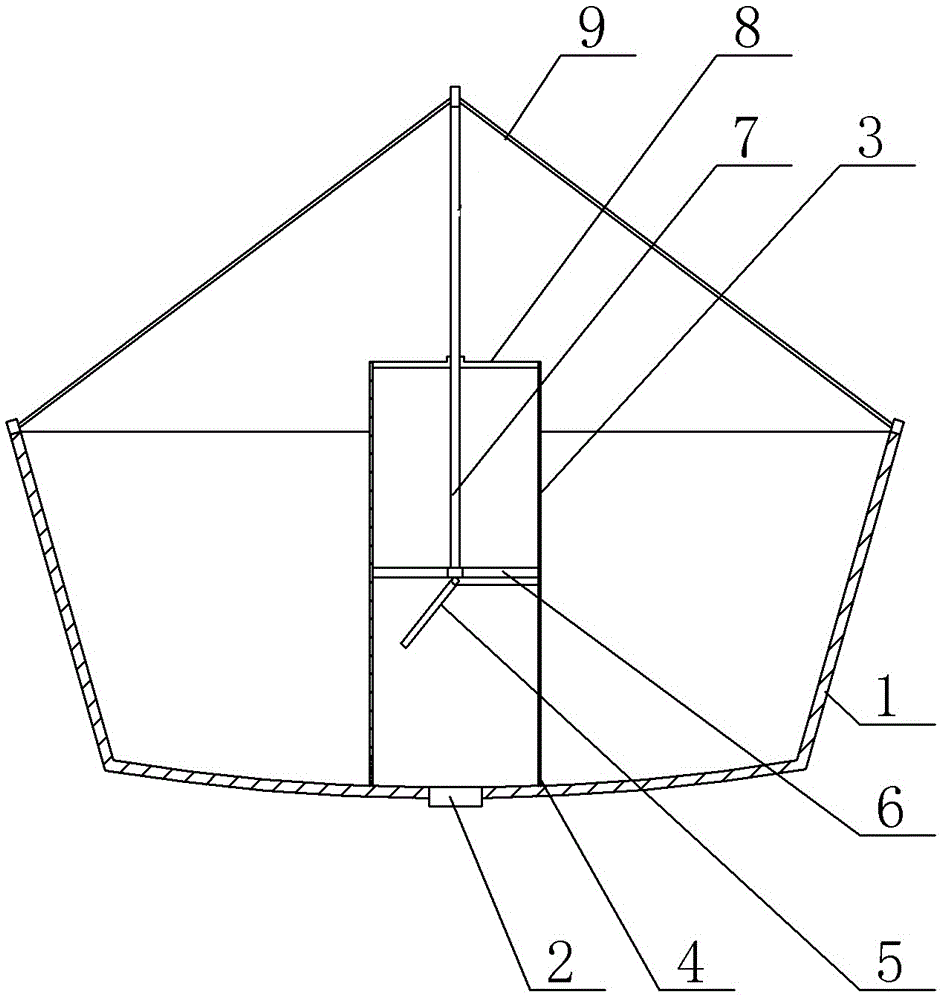

[0026] Such as figure 1 with figure 2 Shown: the present invention provides a concrete pumping pipeline cleaning method and a special device,

[0027] The special device includes: a hopper 1, the bottom of the hopper 1 is provided with a suction port 2 of the pumping machine, and a vertical cylindrical ice inlet tube 3 is connected around the suction port 2, the material of the ice tube 3 is preferably stainless steel, and the outer wall can be A hoop is added, and a water inlet 4 is provided on the lower side wall of the ice inlet cylinder 3. The size of the water inlet 4 should ensure that the ice cubes will not be squeezed out, so the diameter of the water inlet should generally be kept at 2 to 5 mm. , preferably 3 mm in the present application, a hole-shaped pressing plate for pushing ice cubes is set in the ice inlet tube 3, and the hole-shaped pressing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com