Defrosting-free air cooling and water cooling all-in-one machine air source heat pump

An air source heat pump and all-in-one technology, applied to refrigerators, compressors, refrigeration components, etc., can solve the problems of low cooling coefficient in summer, unreliability, and unscientific defrosting in winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

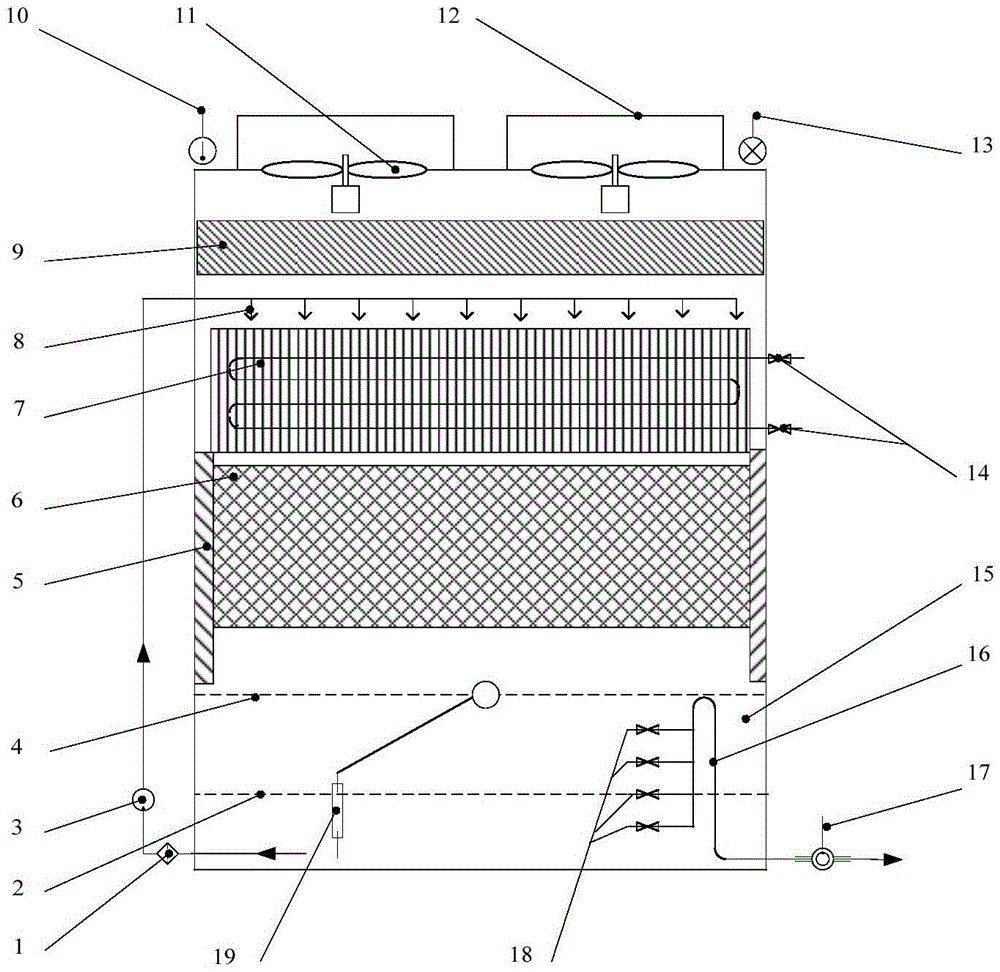

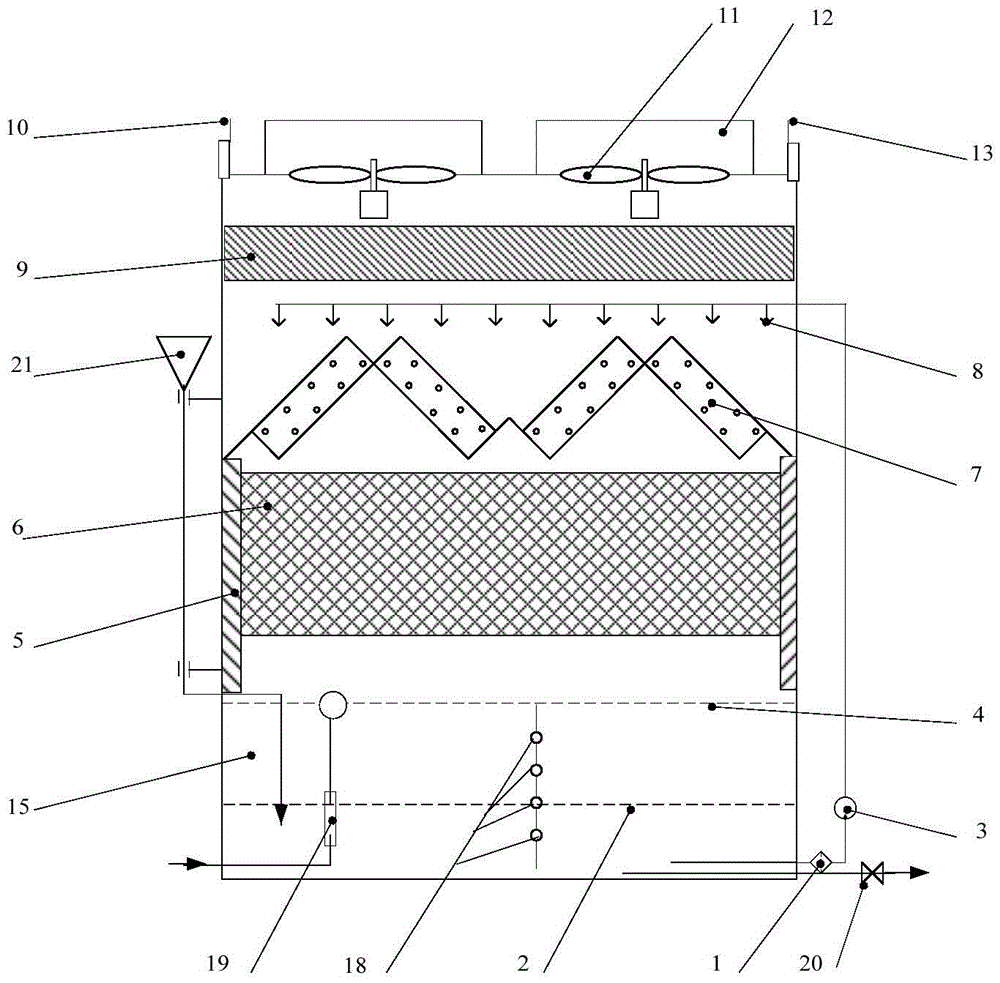

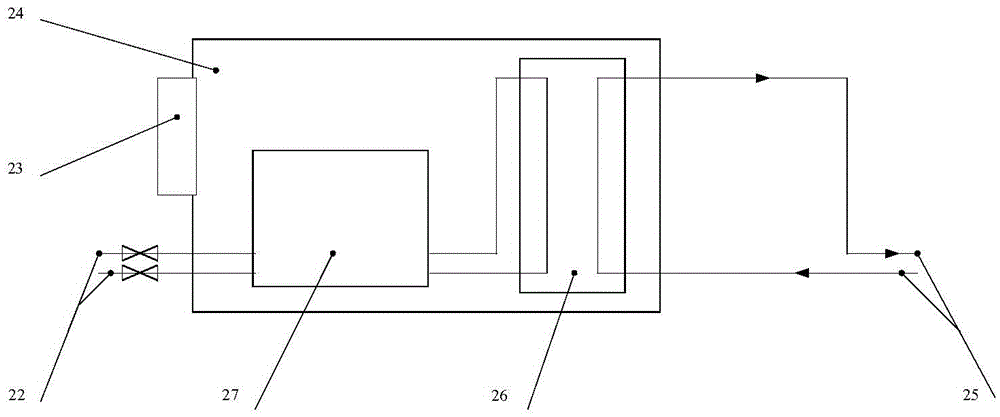

[0049] Referring to the figure, the present invention provides a frost-free air-cooled, water-cooled all-in-one air source heat pump, which is composed of an air heat exchange component and a heat transfer end component. The air heat exchange component and the heat transfer end component are connected by a pipeline. The circulating medium in the road is refrigerant or refrigerant.

[0050] Air heat exchange components are mainly composed of the following components:

[0051] 1. Filter, 2. Reserve liquid level, 3. Spray water pump, 4. Maximum liquid level, 5. Air intake grille, 6. Grid packing, 7. Fin heat exchanger (circulation medium and air Heat exchanger), 8. Spray head, 9. Water baffle, 10. Temperature sensor, 11. Exhaust fan, 12. Air outlet, 13. Relative humidity sensor, 14. Connecting pipeline vent valve body, 15 , liquid storage tank, 16, antifreeze automatic diversion discharge pipe, 17, water flow switch, 18, reserved liquid level control switch, 19, tap water automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com