Secondary throttle pipe-in-pipe recooling device for air conditioner

A secondary throttling, tube-in-tube technology, applied in the direction of subcoolers, refrigerators, refrigeration components, etc., can solve the problems of unfavorable air conditioner system energy efficiency ratio, large hollow cavity volume, increased manufacturing cost, etc., to achieve improved Market competitiveness, easy processing and manufacturing, and the effect of increasing enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

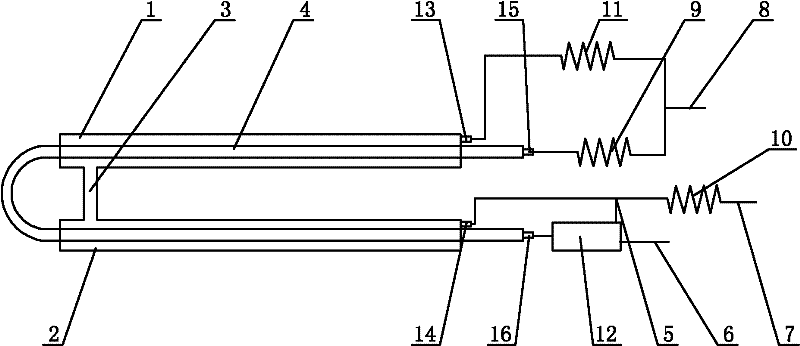

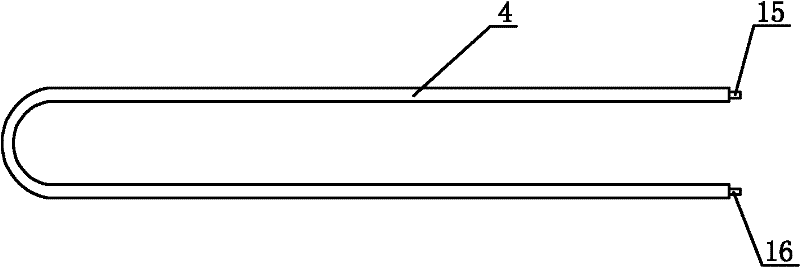

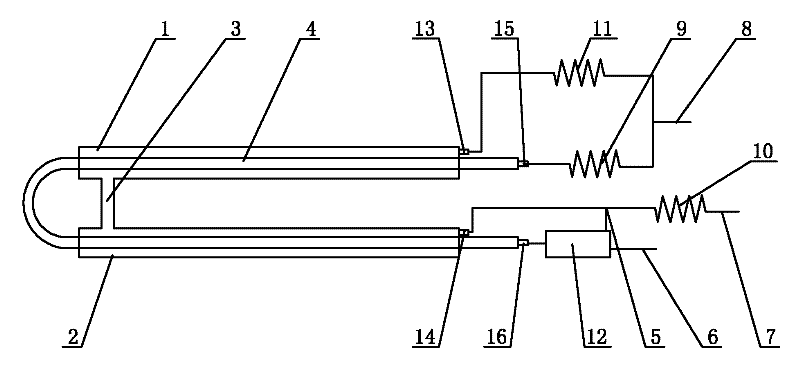

[0016] see Figure 1-Figure 2 , the secondary throttling pipe-in-pipe recooling device of the air conditioner, the device is connected with the primary throttling device on the air conditioning refrigeration circuit, and its secondary throttling pipe-in-pipe recooling device includes a secondary throttling heat exchanger , a throttling piece and a gas-liquid separator 12, the overall shape of the secondary throttling heat exchanger is U-shaped, which includes a first copper tube 1, a second copper tube 2, and a third copper tube welded to each other 3. The fourth copper tube 4, the fourth copper tube 4 is a U-shaped tube; the third copper tube 3 communicates with the first copper tube 1 and the second copper tube 2, and the fourth copper tube 4 The opening ends run through the first copper tube 1 and the second copper tube 2 respectively; the inlet 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com