Single-pivot double row rolling bearing supporting type rotor comprehensive performance experiment device

A rolling bearing and comprehensive performance technology, applied in the field of the comprehensive performance experimental device of the rotor supported by the single fulcrum double row rolling bearing, can solve the problems of shaft holding, catastrophic damage, frequent impact, etc., and achieve the effect of simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

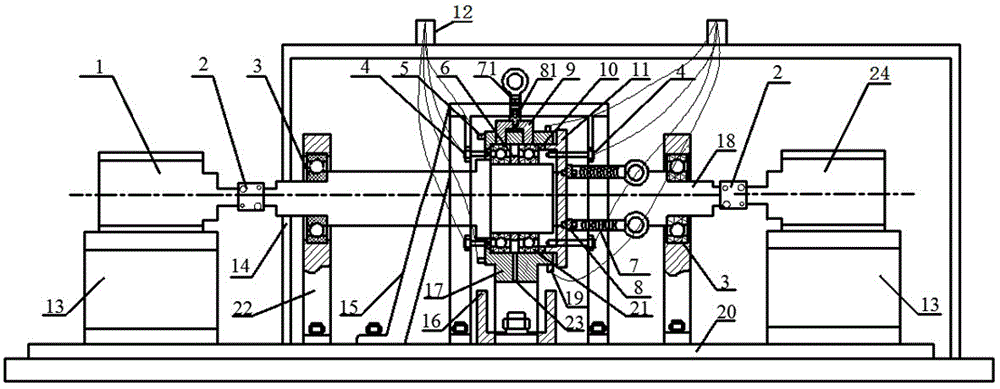

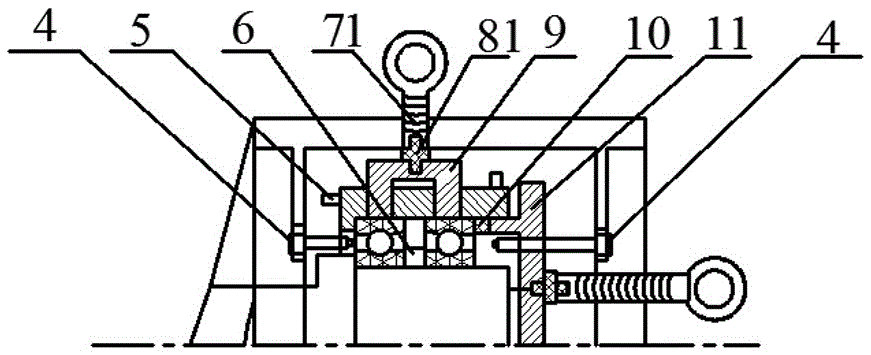

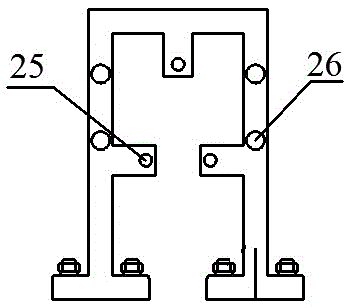

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] like Figure 1-3 As shown, the present invention includes a variable frequency motor 1, a load motor 24, an experimental main shaft 18, two bearing blocks 22, an experimental bench base 20, a loading bracket 15, a double-row rolling bearing 21, an axial loading device, a radial loading device and a protection The cover 14, the variable frequency motor 1, and the load motor 24 are installed on the test bench base 20 through the motor support 13 respectively. The two bearing blocks 22 are fixedly mounted on the test bench base 20, the experimental main shaft 18 is supported on the two bearing blocks 22 by the bearing 3, and the two ends of the experimental main shaft 18 are respectively connected to the variable frequency motor 1 and the load motor 24 through the shaft coupling 2. connect. A double-row rolling bearing is installed between the two bearing housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com