Sliding resistance testing mechanism in universal material testing machine

A technology of material testing machine and sliding resistance, which is applied in the direction of analyzing materials, adopting mechanical devices, measuring devices, etc., can solve the problems that the friction force has a great influence on the experimental results and does not have universality, so as to ensure the accuracy of the test size, Strong versatility and effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

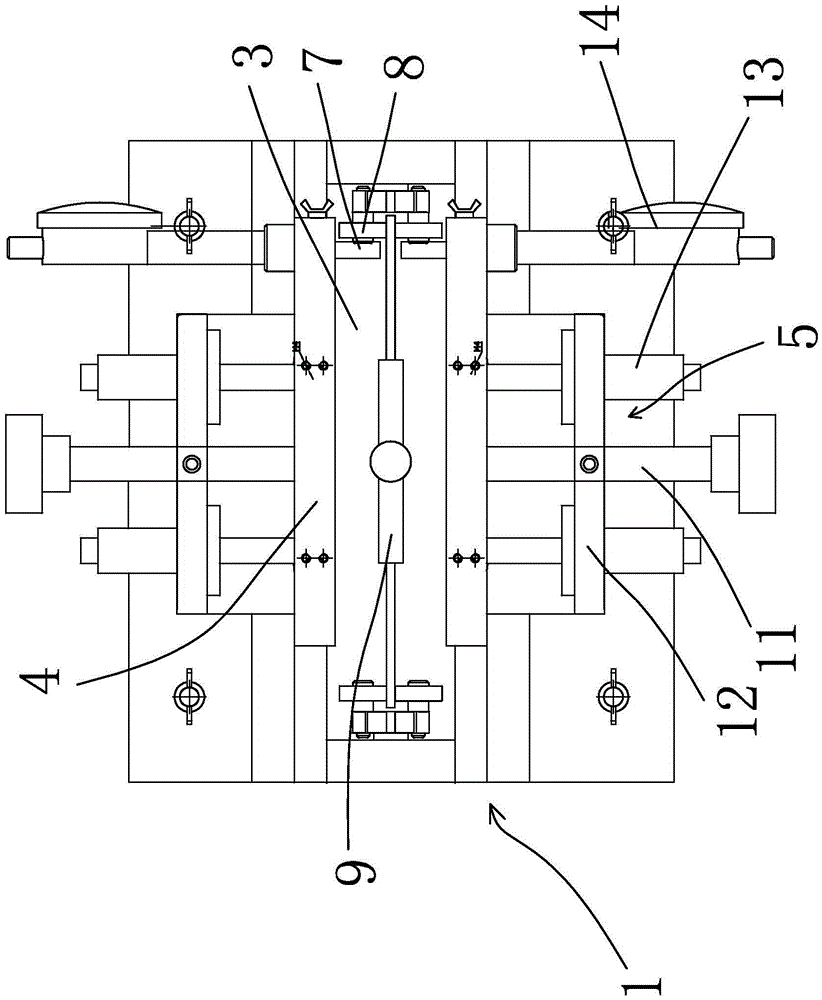

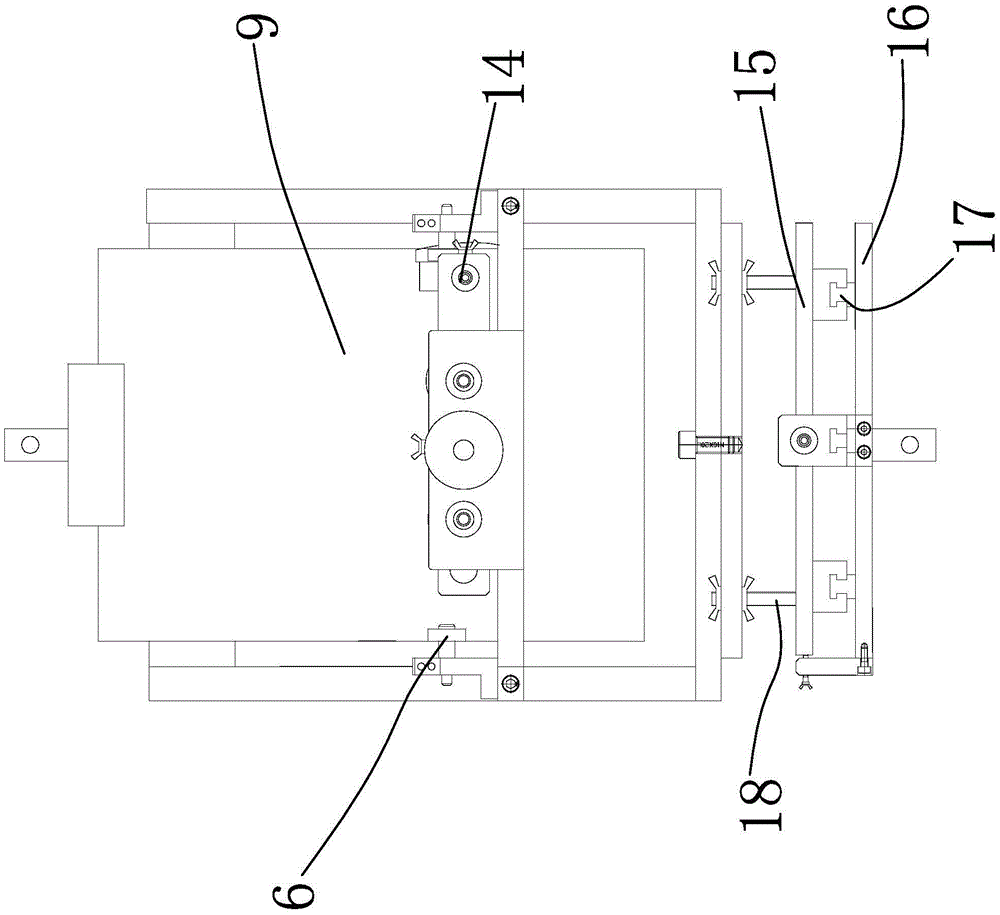

[0018] In the figure, the test platform 1; the adjustment device 2; the test area 3; the product fixing part 4; the thread distance adjustment device 5; the ball bearing guide device 6; the ball bearing 7; Operating rod 11; operating fixture 12; guide 13; dial indicator 14; slide rail platform 15; base 16; slide rail 17; parallel adjustment threaded rod 18; testing machine beam 19; Value sensor 22.

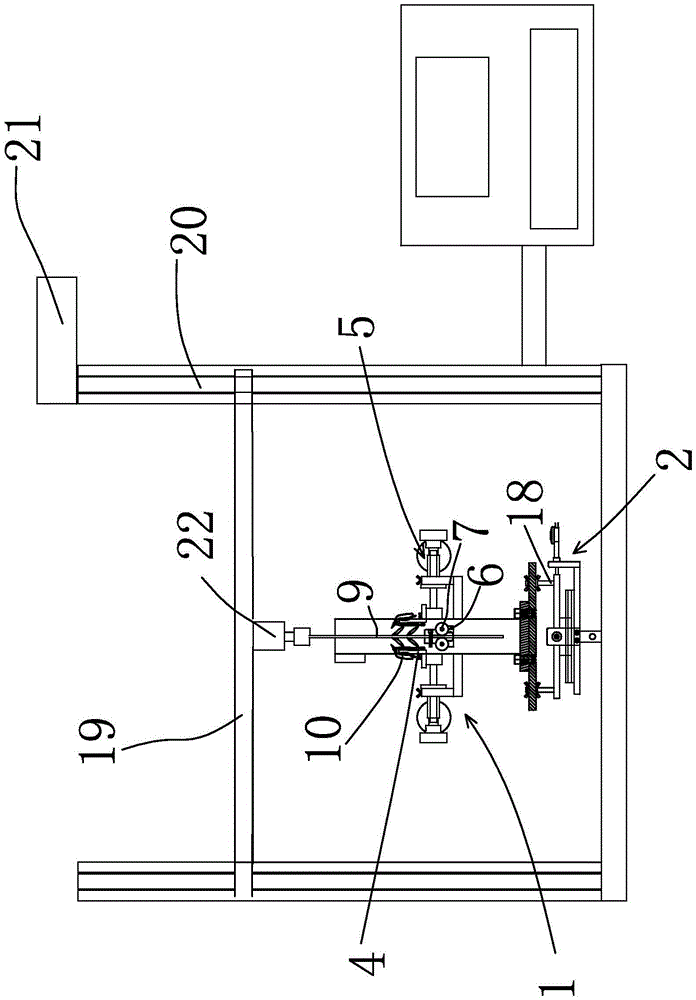

[0019] Such as figure 1 As shown, the sliding resistance test mechanism in this universal testing machine is installed on the universal testing machine as a whole. The sliding resistance testing mechanism includes a test platform 1 and an adjustment device 2 arranged under the test platform 1. The adjustment device 2 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com