Multifunctional testing system and method for natural gas hydrate

A multifunctional testing and natural gas technology, applied in the field of testing, can solve problems such as unobtainable, special order, no judgment of natural gas hydrate structure type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

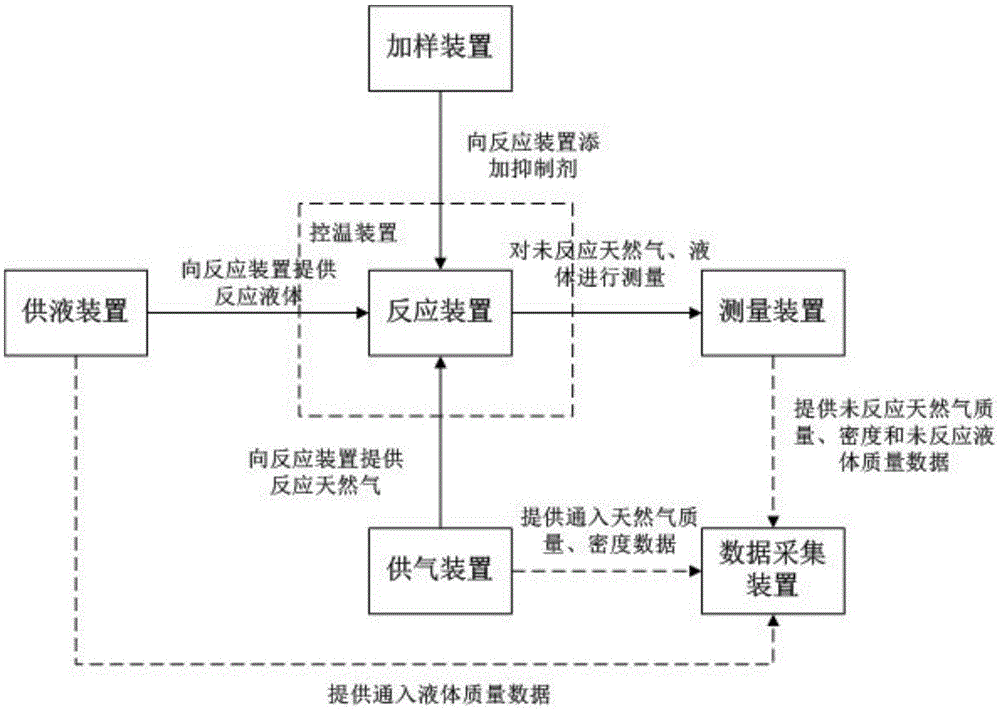

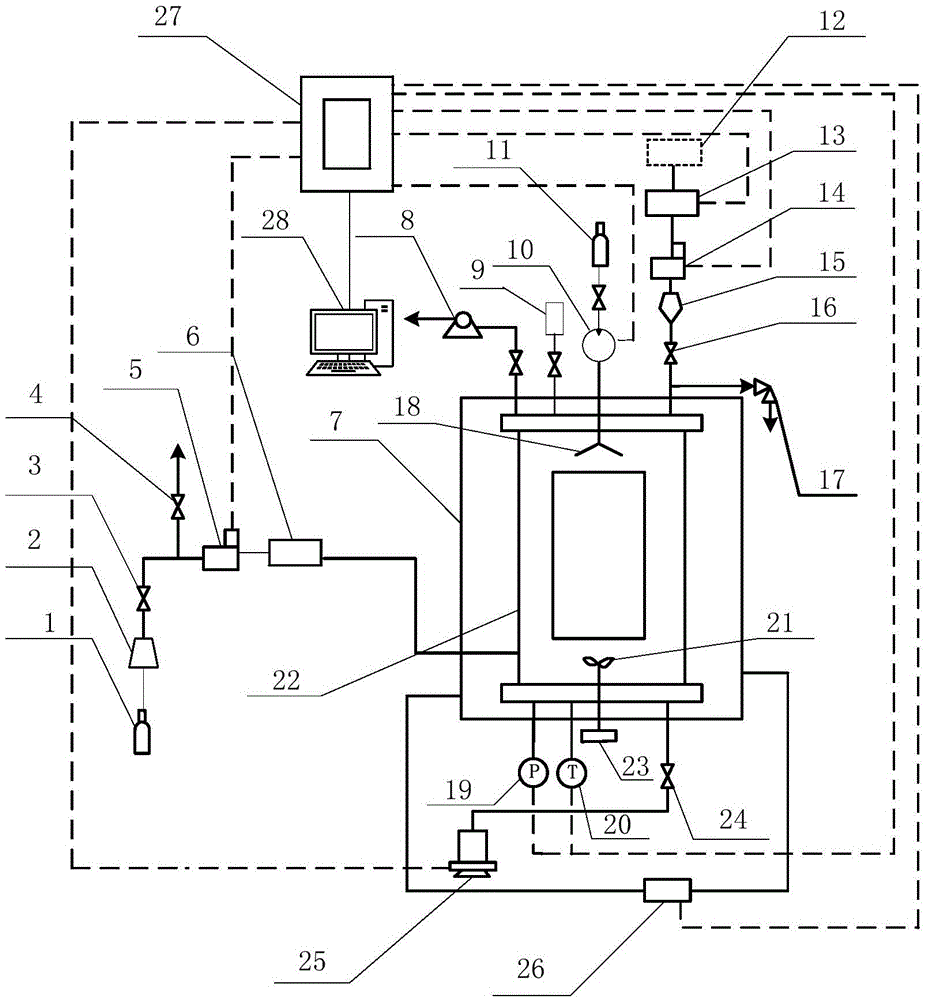

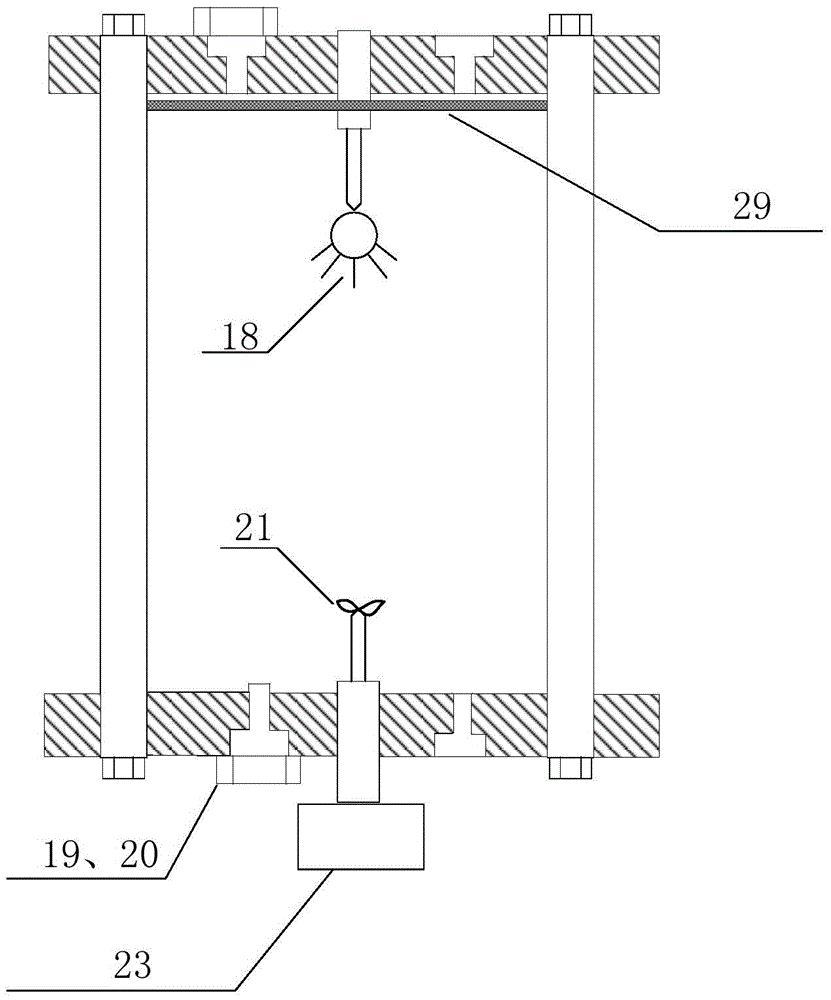

[0069] like figure 1 As shown, the present invention provides a multi-functional testing system for natural gas hydrate, including: a gas supply device, a liquid supply device, a sampling device, a reaction device, a measurement device, a temperature control device and a data acquisition device. The gas supply device communicates with the reaction device and is used to supply reaction gas to the reaction device. The first mass flow controller 5 provided on the gas supply device is connected to the data acquisition device. The liquid supply device communicates with the reaction device and is used to provide reaction liquid to the reaction device, and the metering pump 10 on the liquid supply device is connected with the data acquisition device. The sample adding device communicates with the reaction device and is used for adding inhibitors to the reaction device. The reaction device is used to mix the reaction gas and the reaction liquid to generate natural gas hydrate; the re...

Embodiment 2

[0102] The present invention further provides a multifunctional test method for natural gas hydrate, according to the obtained initial gas quality m 1 , liquid mass m 2 , the mass of unreacted natural gas m 3 , liquid mass m 4 , the density ρ of the incoming natural gas 1 , Density ρ of unreacted natural gas 2 , and the gas hydrate formation temperature T and pressure P, combined with the following method, can obtain the generated gas hydrate quality and / or the generated gas hydrate structure type while generating gas hydrate;

[0103] S1: The step of obtaining the quality of the generated natural gas hydrate is: let m 进 = m 1 +m 2 , m 未 = m 3 +m 4 , then the mass of gas hydrate formed is m=m 进 -m 未 ;

[0104] S2: The steps to obtain the structure type of the generated natural gas hydrate are: according to the density ρ of the incoming natural gas 1 , Density ρ of unreacted natural gas 2 As well as the temperature T and pressure P of gas hydrate formation, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com