Steel coil quality detection system

A steel coil and quality technology, applied in the field of steel coil quality inspection system, can solve the problems of unable to judge the quality of steel coil, unable to quantify the quality of steel coil, and unable to locate the surface of steel coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

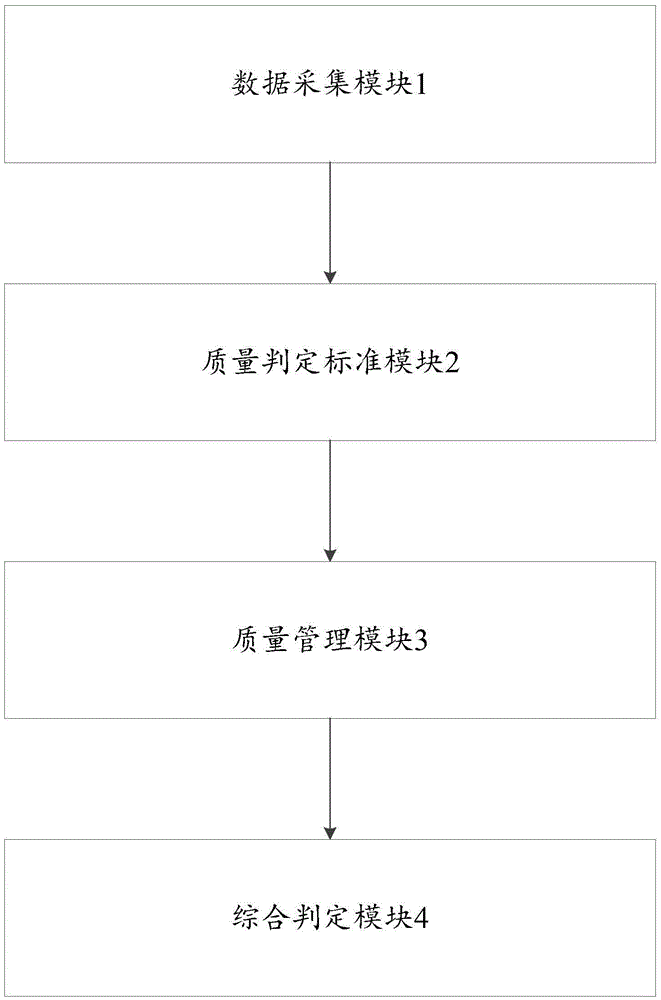

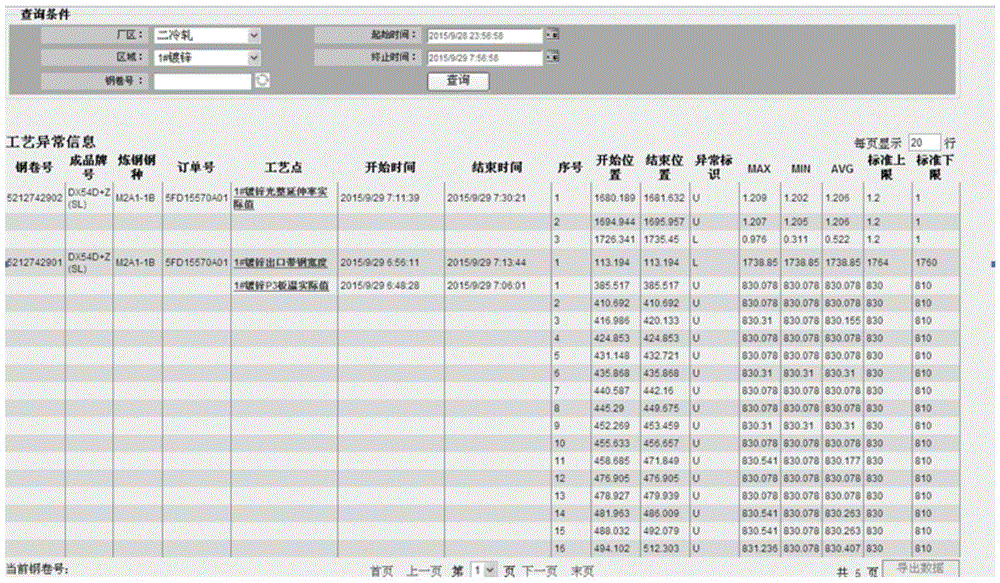

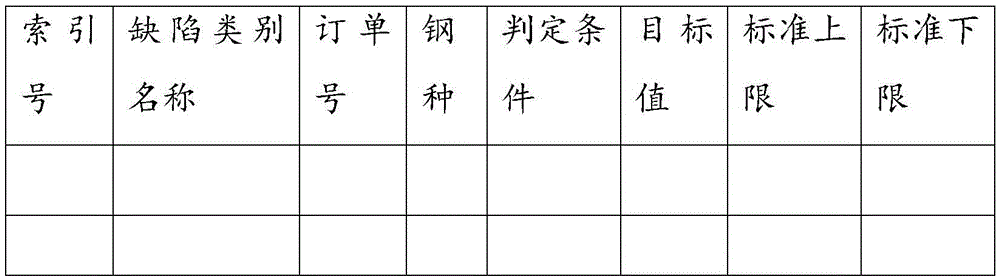

[0027] In order to quantitatively detect the quality of the steel coil during the production process, locate the specific defect position on the surface of the steel coil, and perform online judgment on the quality of the steel coil, the present invention provides a steel coil quality detection system, the system comprising: Data acquisition module, the data acquisition module is used for real-time acquisition of steel coil production process data, steel coil surface detection data and production plan data; quality judgment standard module, the quality judgment standard module is used to establish the steel coil surface defect judgment standard Library, steel coil surface defect judgment level definition table, process parameter judgment standard library and process quality level definition table; quality management module, the quality management module is used for judging the standard library according to the steel coil surface defect and the steel coil surface Defect judgment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com