Split connecting plug with tail sleeve

A split type and plug technology, which is applied in the direction of connection, contact parts, two-part connection device, etc., can solve the problems of poor sealing between the plug and the wire, no shaking of the wire end, and reduced stability of the electrical connection, etc., so as to achieve easy penetration , flexible use, and the effect of reducing contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

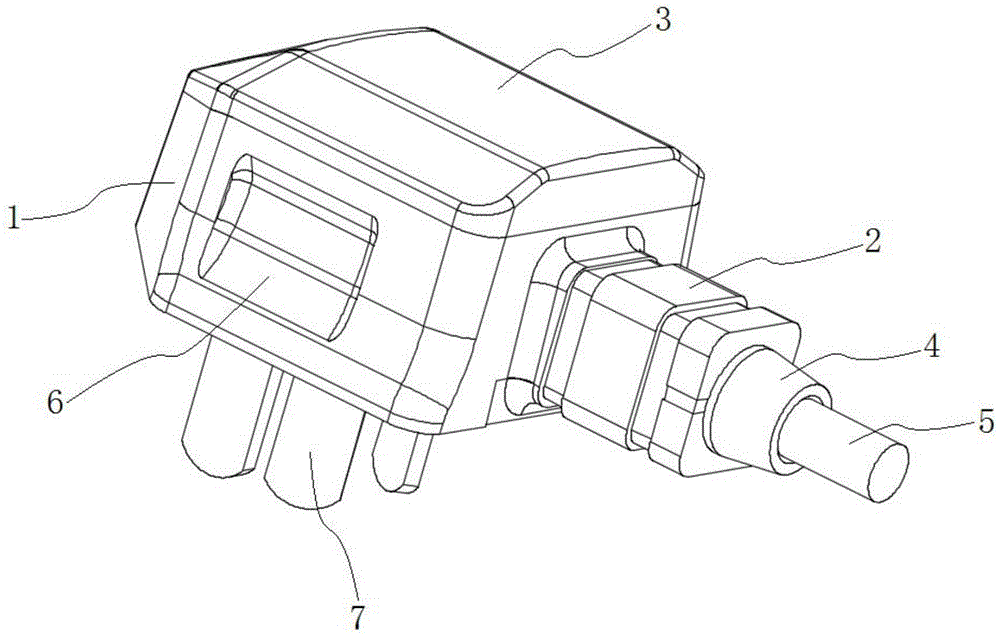

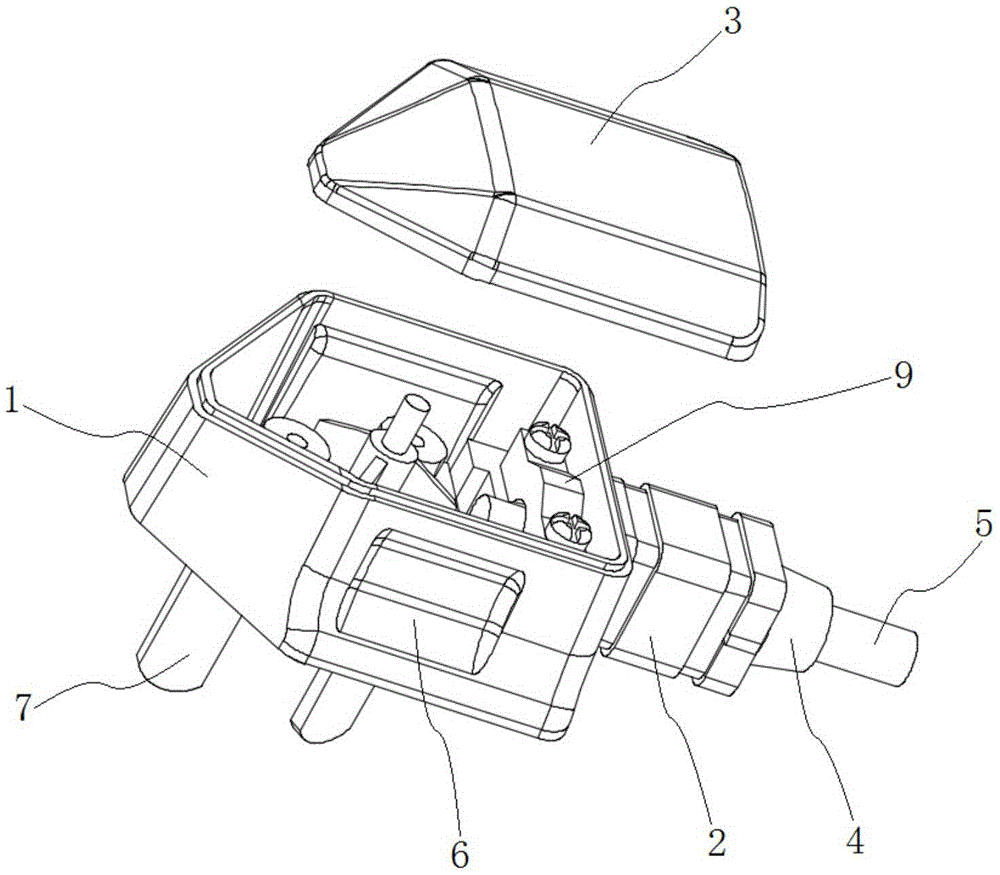

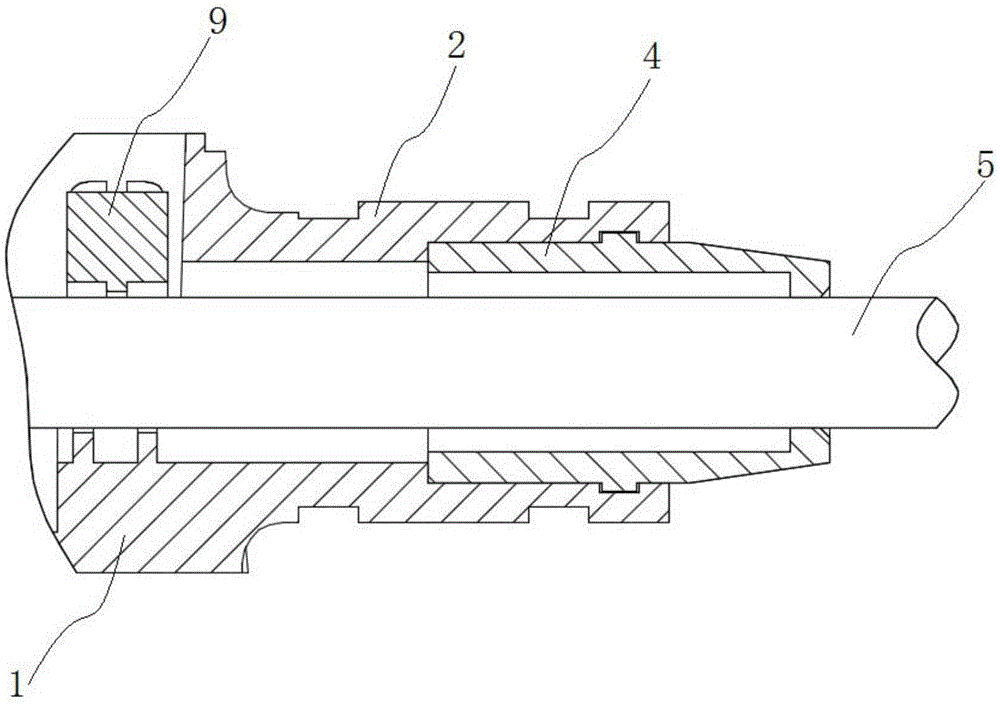

[0038] combine figure 1 and figure 2 As shown, a split terminal plug with a boot in this embodiment includes a plug base 1, an upper cover 3 and a plug electrode assembly, and the plug electrode assembly is arranged on the plug base 1, and in this embodiment , the plug electrode assembly is a blade assembly 7, that is, the split terminal plug is a blade plug, the plug electrode assembly and the plug base 1 can be integrally formed by screw connection or hot-melt connection or injection molding, and the blade assembly 7 can be formed in advance Injection molding is adopted; the electrodes in the plug assembly 7 are integrally formed, that is, the plug and the terminal are integrally formed, which avoids the problem of electrode loosening caused by riveting during the wiring process, thereby effectively solving the problem of electrode heating and improving the plug. service life; the upper cover 3 is installed on the plug base 1 and is detachable. Specifically, the upper cove...

Embodiment 2

[0043] combine Figure 5 and Figure 6 As shown, the basic structure of a split-type wiring plug with a boot in this embodiment is the same as that in Embodiment 1, the difference is that the plug electrode assembly in this embodiment is a plug-in bolt assembly 8, that is, a split-type The wiring plug is a plug-in plug. The electrodes in the plug-in plug assembly 8 are composed of integrally formed contacts, conductive rods and terminal posts. Similar to Embodiment 1, the integrally formed electrodes ensure that the heat generation of the electrodes is small. Longer life. The plug bolt assembly 8 and the plug base 1 can also be connected by screws, hot-melt connection or injection molding, and the plug bolt assembly 8 can be made separately. Specifically, the plug bolt assembly 8 consists of a plug shell , electrodes and electrode mounting plugs, etc., during production, the plug shell can be connected to the plug base 1, and then the electrodes are assembled into the plug s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com