Control valve

A control valve and valve seat technology, which is applied to fuel injection valves, engine components, machines/engines, etc. driven by fluid pressure, can solve problems such as the adverse effect of control valve switching time, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

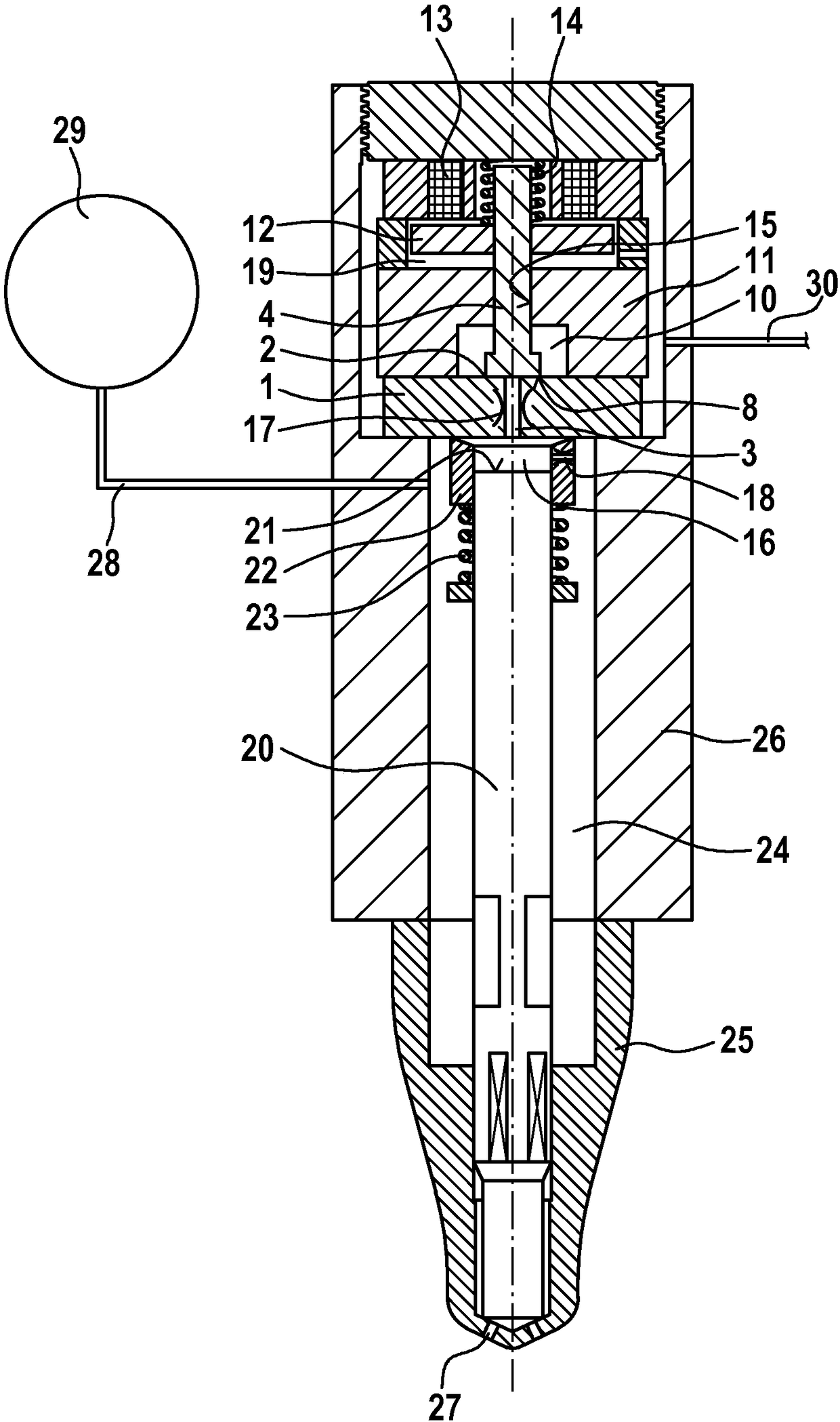

[0034] figure 1 The fuel injector shown in has a nozzle body 25 and a holding body 26 which are axially clamped by means of a clamping nut, not shown. The nozzle body 25 and the holding body 26 are penetrated by a high-pressure bore 24 in which the nozzle needle 20 is accommodated in a reciprocating linear motion for releasing or closing the injection opening 27 . The high-pressure opening 24 is connected via a supply line 28 to a high-pressure accumulator 29 , via which fuel under high pressure is delivered to the high-pressure opening 24 .

[0035]The high-pressure bore 24 is delimited in the axial direction by the valve block 1 of the control valve for controlling the reciprocating linear movement of the nozzle needle 20 , which is inserted into the holding body 26 . The valve block 1 seals off the high-pressure opening 24 from the low-pressure chamber 10 which is formed within the valve body 11 of the control valve. Through the hole 15 of the valve body 11 and through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com