Methacrylaldehyde catalyst and preparation method thereof

A technology of methacrolein and catalyst, which is applied in the field of methacrolein catalyst and its preparation, can solve the problems of low yield of methacrolein and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

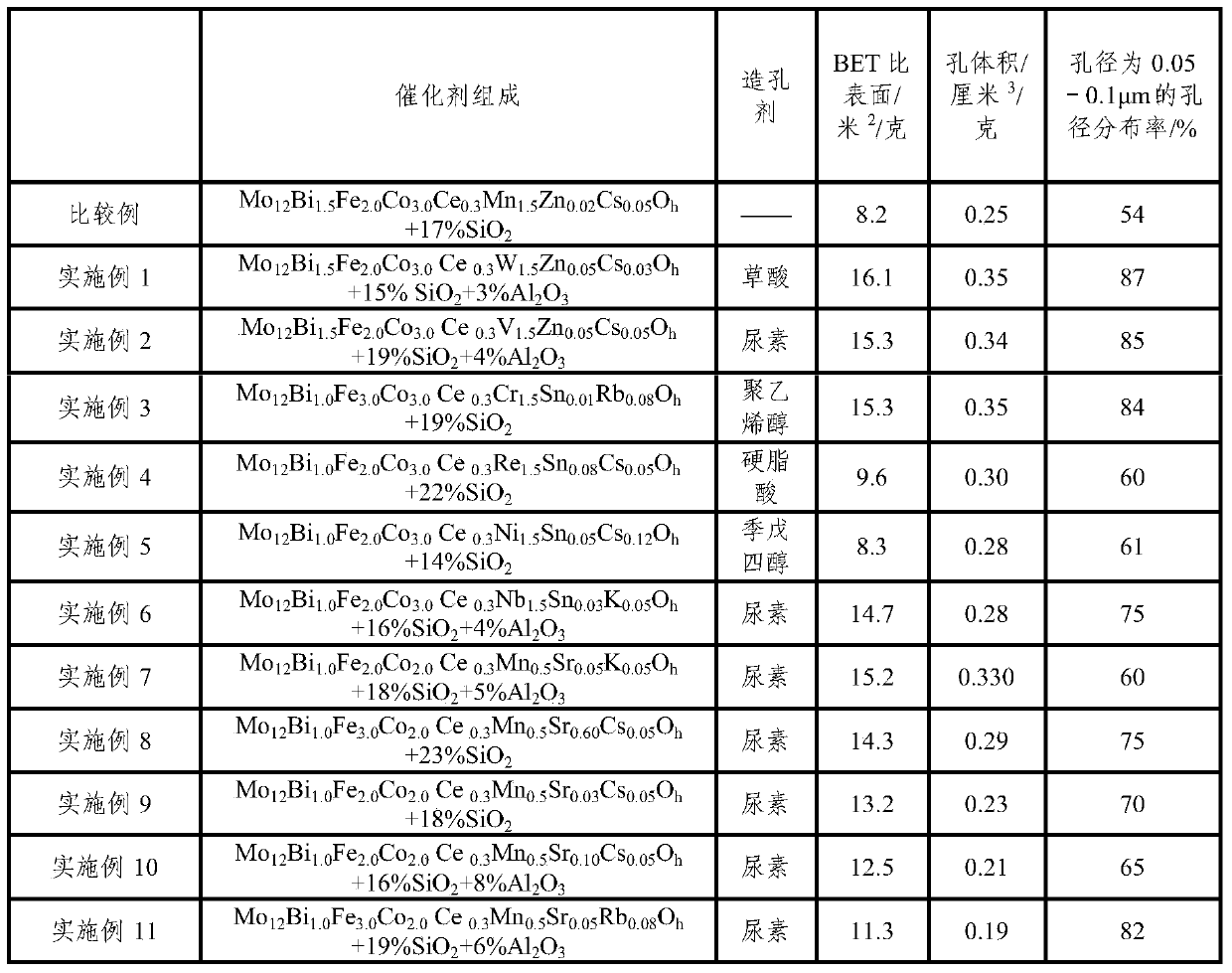

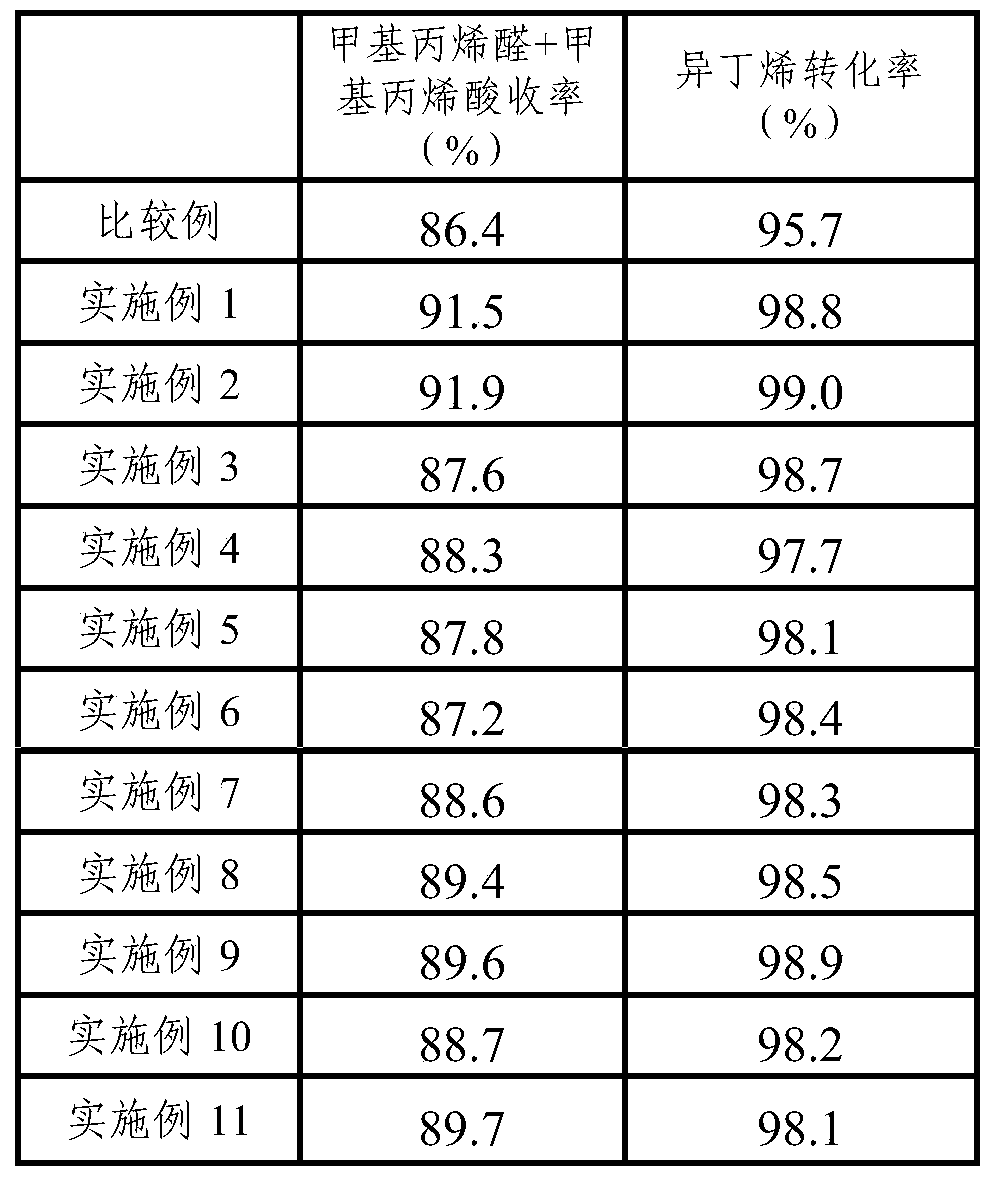

Examples

Embodiment 1

[0033] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of warm water at 70°C, stirred to dissolve it completely, and 89.4 grams of 40wt% silica sol and 35.8 grams of 20wt% aluminum sol were added and mixed to obtain material A.

[0034] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of hot water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 6.1 g Ce(NO 3 ) 3 ·6H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.3 g CsNO 3 and 19.1 g (NH 4 ) 6 h 5 [H 2 (WO4 ) 6 ] stirring and dissolving to make material B.

[0035] Add material B to material A to form a catalyst slurry, add 5.13 grams of oxalic acid, dry at 120°C, extrude to obtain a cylindrical object of φ3.5x3.5mm, and then calcine at a high temperature to obtain a finished catalyst. The calcination temperature is 450°C . The catalyst composition and preparation conditions are listed in Table 1, at 350 ° C, reaction space velocity 1200 hours -1 The ...

Embodiment 2

[0037] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of warm water at 70°C, stirred to dissolve it completely, and 78.9 grams of 40wt% silica sol and 47.7 grams of 20wt% aluminum sol were added to make material A.

[0038] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of hot water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 6.1 g Ce(NO 3 ) 3 ·6H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.5 g CsNO 3 and 8.24 g NH 4 VO 3 Stir to make ingredient B.

[0039] Add material B to material A to form a catalyst slurry, add 5.13 grams of urea, dry at 120°C, and extrude to obtain a cylindrical object of φ3.5x3.5mm, and then roast at a high temperature to obtain a finished catalyst. The roasting temperature is 450°C . The catalyst composition and preparation conditions are listed in Table 1, at 350 ° C, reaction space velocity 1200 hours -1 The results are listed in Table 2.

[0040] Embodiment 3-11 mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com