Band saw blade

A band saw blade and saw tooth technology, which is applied in metal sawing equipment, sawing machine tools, metal processing equipment, etc., can solve the problems of unguaranteed section roughness, difficulty in guaranteeing the accuracy of tooth division, uneven cutting force, etc. , to achieve the effect of improving shape, avoiding sawing and improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

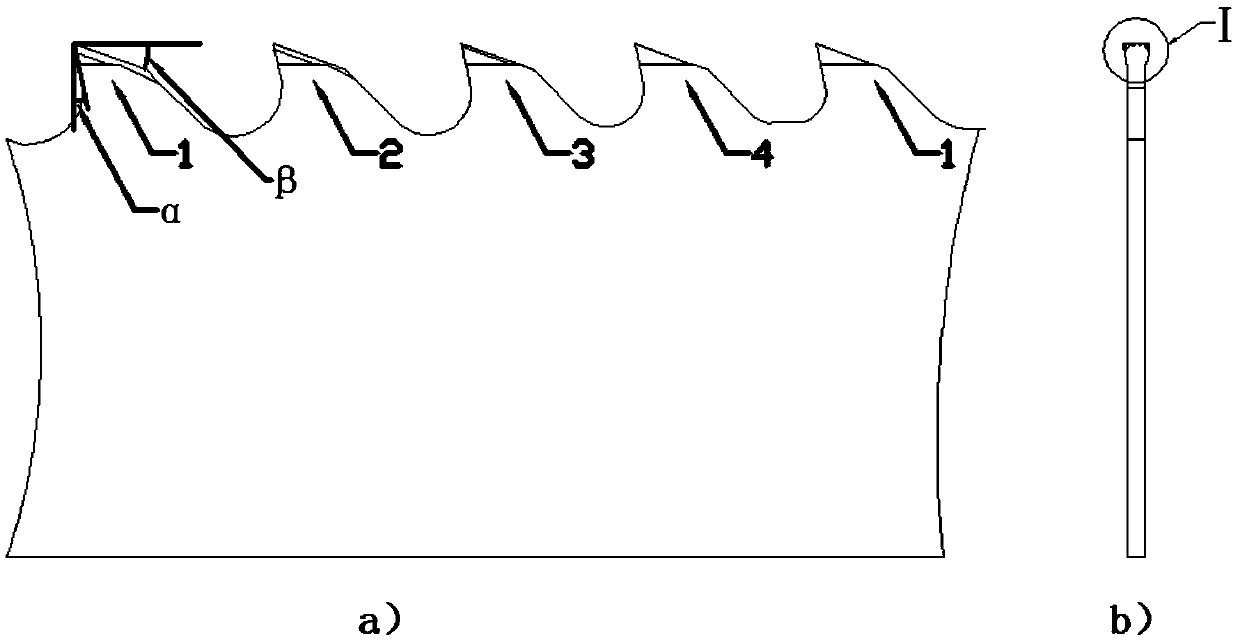

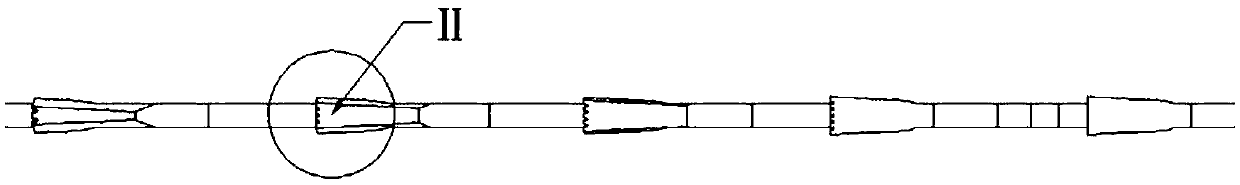

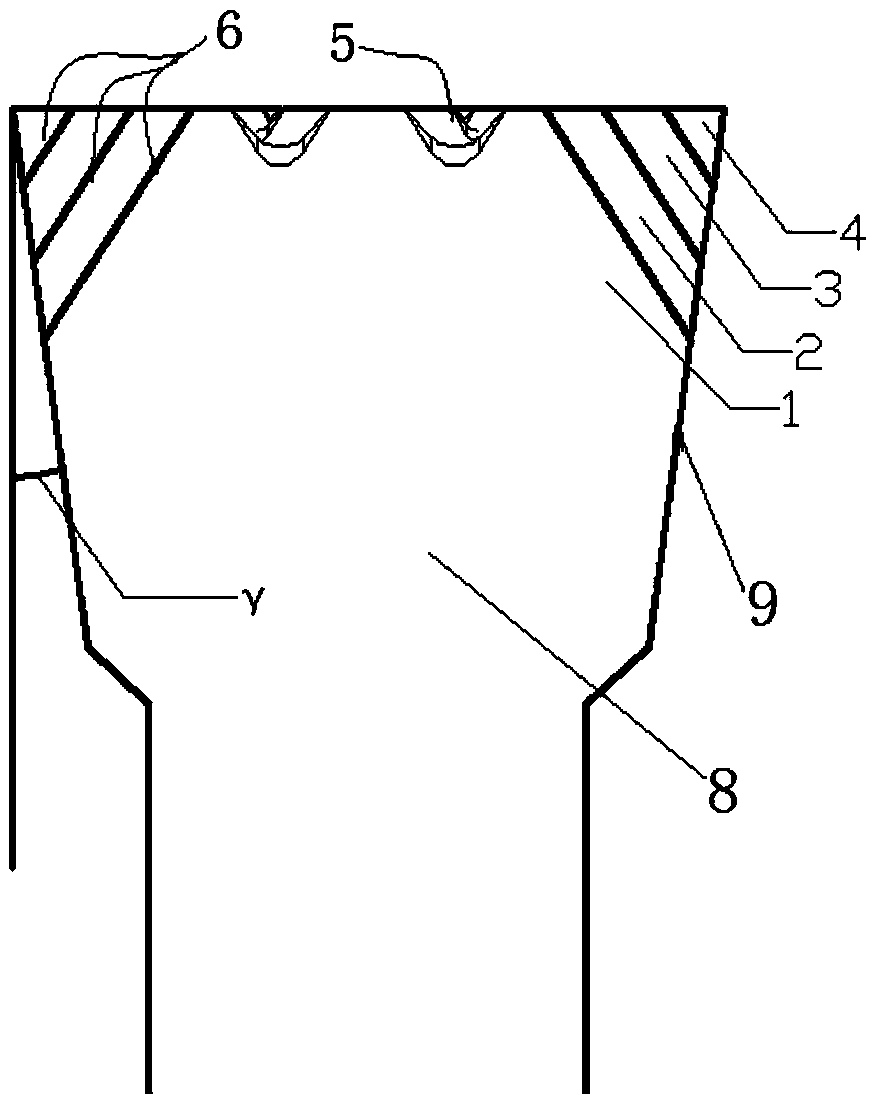

[0036] A non-toothed band saw blade, including saw teeth arranged continuously, and adjacent 4-9 saw teeth form a group, such as Figure 5 As shown, the rear angle surface 8 and the side angle surface 9 of each sawtooth form an included angle chamfer 6, and the length of the hypotenuse of the included angle chamfer decreases successively. Each sawtooth 1, 2, 3, 4 is provided with grooves 5, the number of grooves 5 increases gradually, ranging from 2 to 7, and the width and depth of grooves 5 gradually decrease. The angle between the side angle surface of the band saw blade and the width direction of the band saw blade (radial side angle γ) is 5-10°, and the angle between the side angle surface and the length direction of the band saw blade (tangential side angle δ) is 5-10° . The angle of the chamfer formed by the back angle surface and the side angle surface of the band saw blade is consistent, and the range is 45-60°

[0037] The chamfering and slotting of the patented too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com