A method for manufacturing a space curved steel member

A technology of space curve and manufacturing method, which is applied in the field of manufacturing space curve steel components, can solve the problems of difficult to achieve beautiful appearance of bridges, uneven and smooth bridge line shape, etc., and achieve low cost, increased manufacturing cost and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

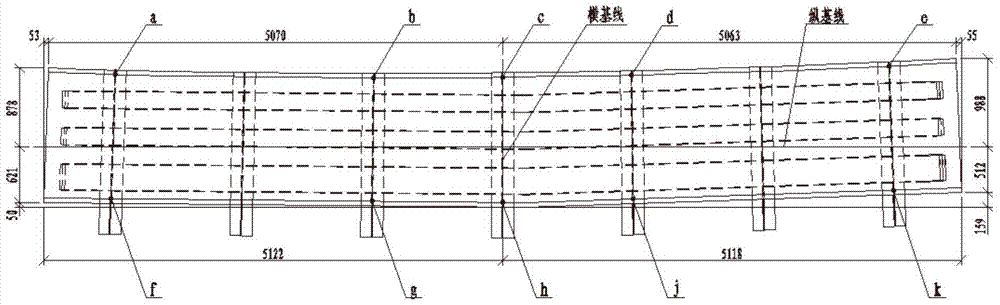

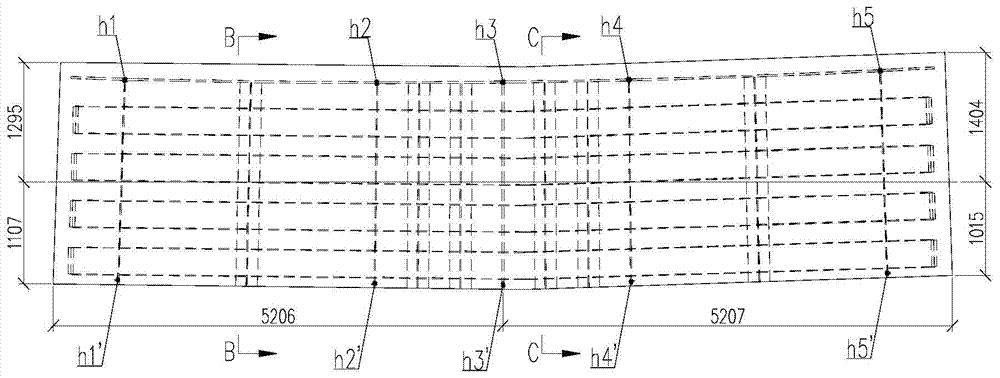

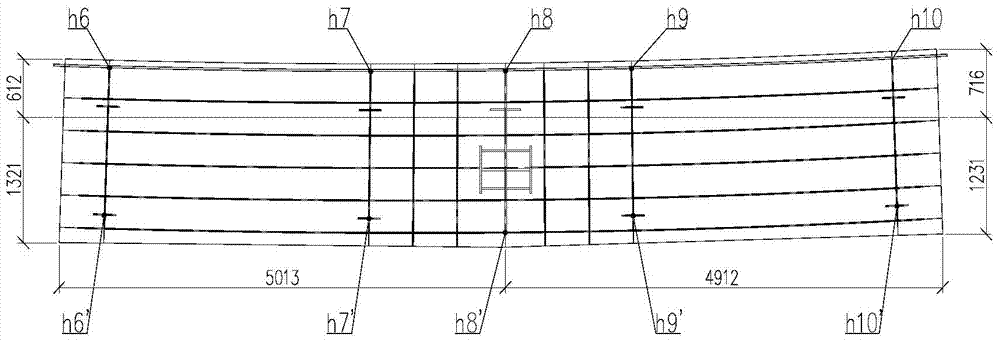

[0018] Embodiment 1: with reference to attached Figure 1-5 . A manufacturing method of space curved steel components, (1) Requirements for parts production: steel plates must be pretreated to eliminate rolling stress and transport residual stress in steel plates, use three-dimensional analysis software to loft curved structures, and calculate the expansion of space curved plates Shape, combined with the manufacturing process to add flame cutting compensation amount, deformation process amount, welding process amount, etc., through high-precision numerical control flame cutting equipment to make parts; for the partition of the space curved steel component, because it is an inner tube assembled by steel components , the size should be strictly controlled and realized by mechanical processing; (2) surface forming requirements: according to the line shape of the space curve plate, the minimum curvature of the space curve plate along the length direction of the plate is analyzed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com