A fully automatic circlip assembly machine for shafts

A fully automatic and assembly machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inaccurate visual observation of assembly, affecting product production and assembly efficiency, and inability to guarantee assembly quality, etc., to achieve improvement The effect of assembly quality, simple structure and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

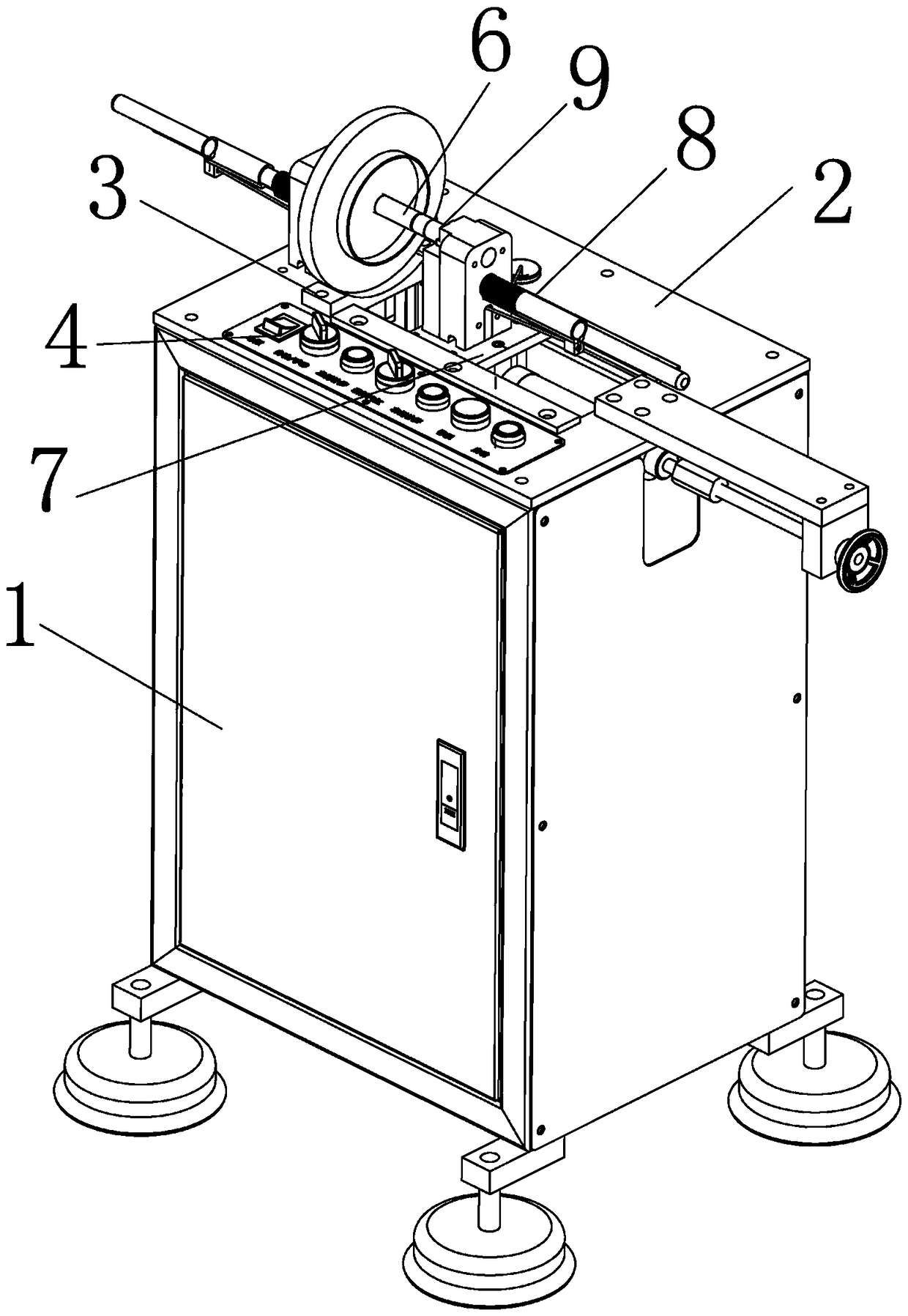

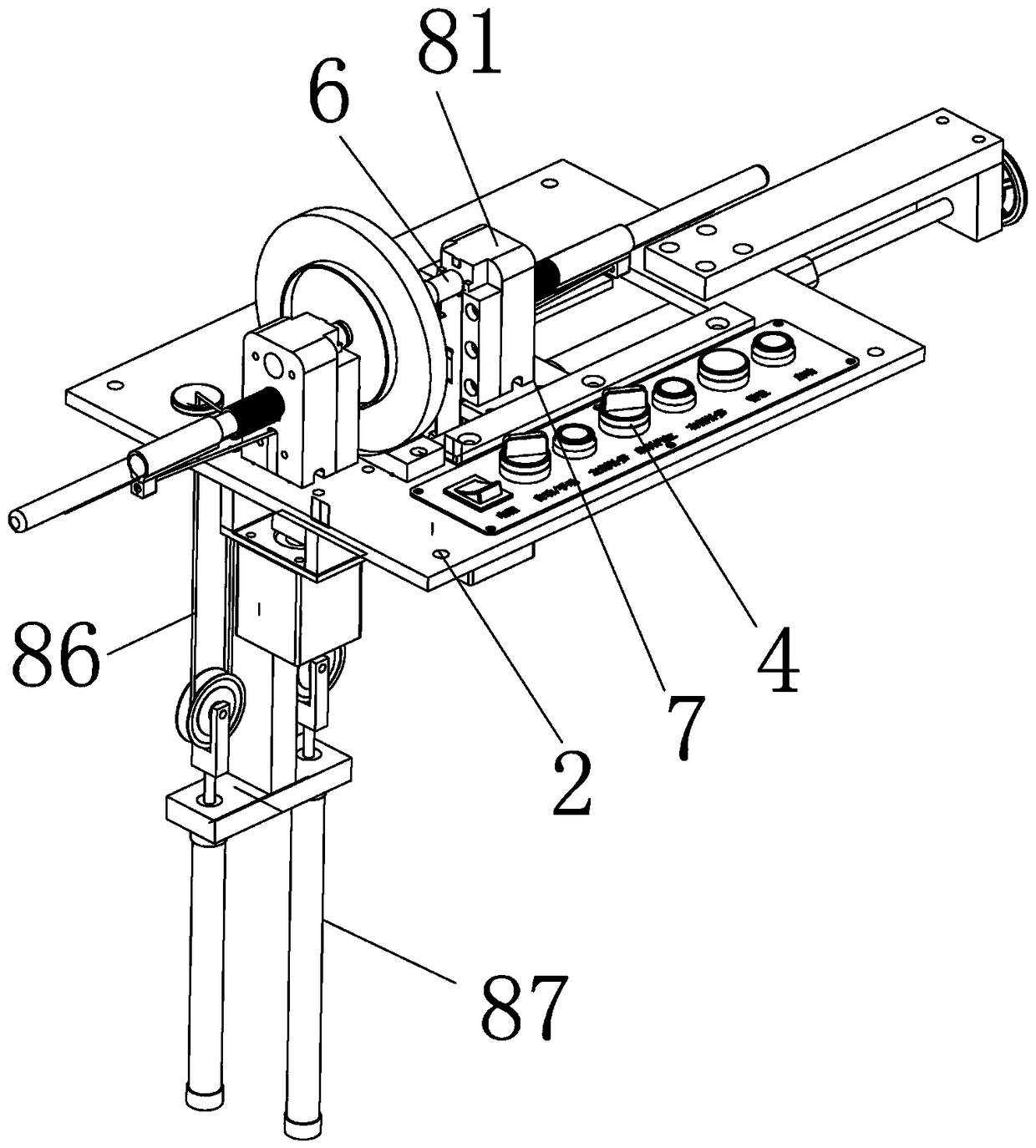

[0024] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A fully automatic circlip assembly machine for shafts, characterized in that it includes a main frame 1 and a table top 2 on it, and the table 2 is equipped with a shaft fixing seat 3, a control system 4 and a circlip expander that can clamp After the spring 5 expands, the snare is caught on the rotating shaft 6,

[0025] The circlip expander includes:

[0026] 1) The horizontal sliding table 7 that can move relative to the fixed seat 3 of the rotating shaft;

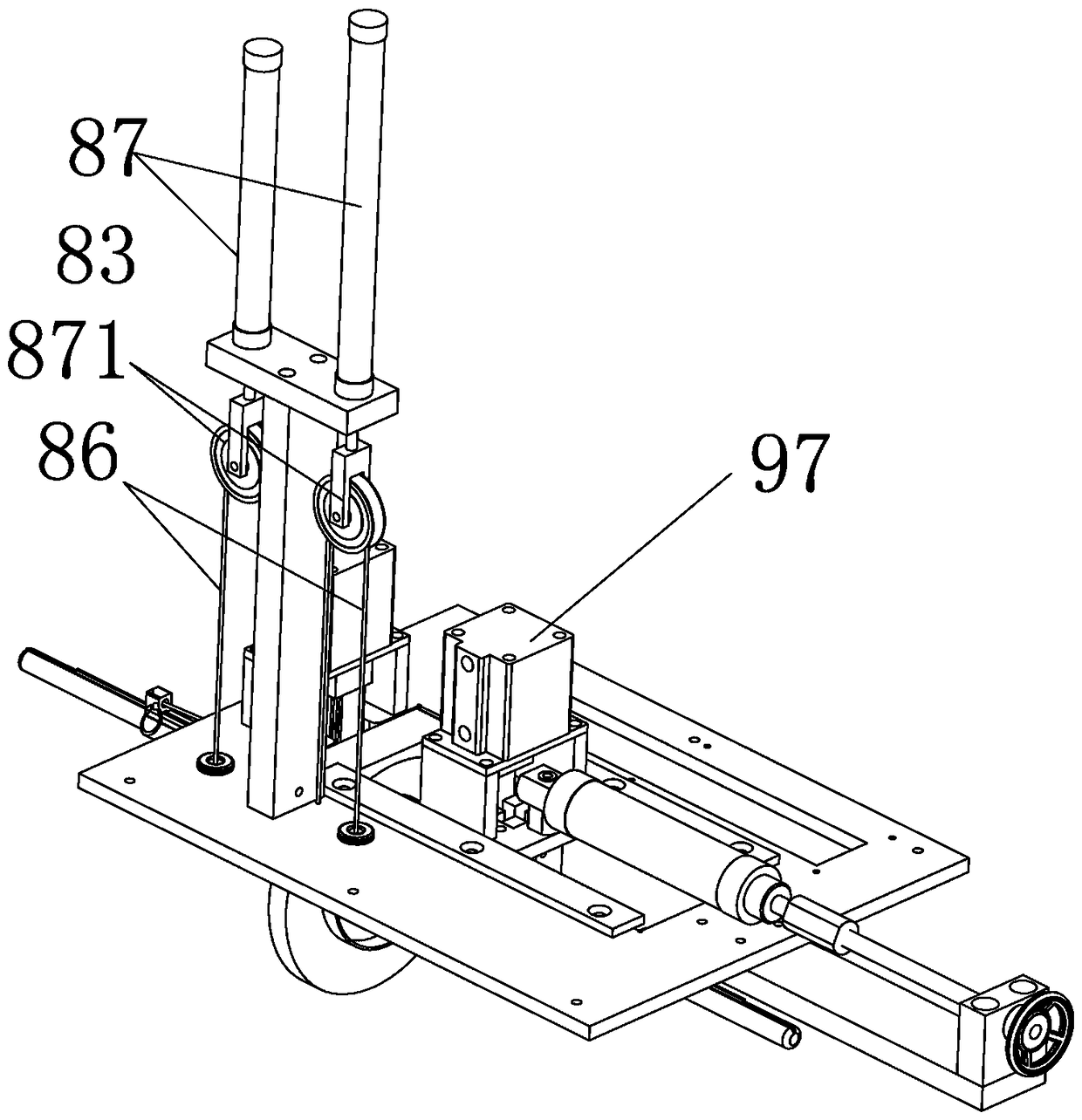

[0027] 2) The spring feeder 8 installed on the horizontal slide 7;

[0028] 3) The circlip bulging seat 9 docked with the circlip feeder 8 .

[0029] There are two sets of the circlip expander, which are symmetrically installed on the left and right ends of the rotating shaft fixing seat 3 .

[0030] One of the circlip expanders is fixed on the table 2, and the other set is installed on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com