Processing and producing line of simple axillary crutch

A technology of production line and crutches, applied in the direction of crutches, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low mechanization level, low output, high scrap rate, etc., and achieve high mechanization level, high output, and low scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

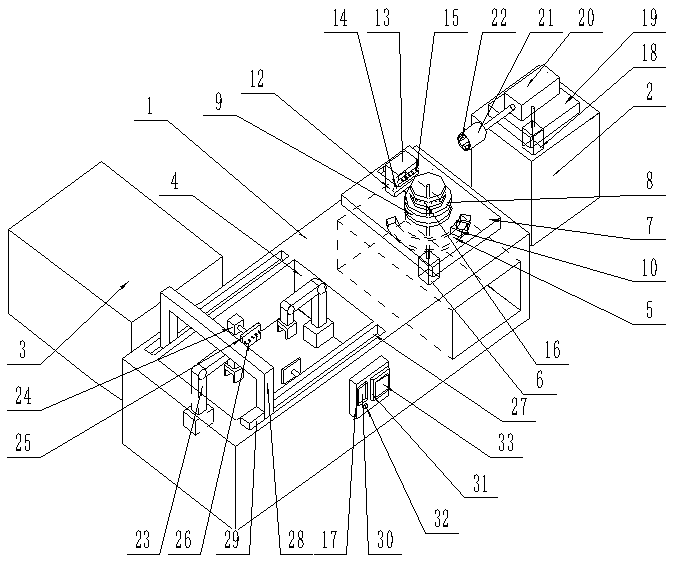

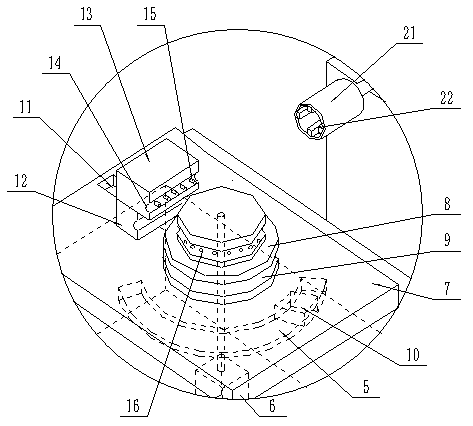

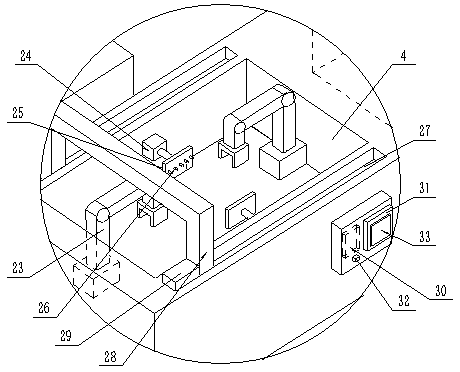

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a simple underarm abduction processing production line includes workbench A (1), workbench B (2) set on the right side of workbench A (1) and branch pipe set on the back side of workbench A (1) Conveyor belt (3), the workbench B (2) is provided with a reversing propulsion unit, the inside of the workbench A (1) is a cavity structure, and the workbench A (1) is close to the workbench B ( 2) is provided with a turning body forming unit at one end, and the workbench A (1) is provided with a working groove (4), and the workbench (4) is provided with a clamping unit and a milling unit, and the workbench A (1) is provided with a welding unit on the part of the notch of the working tank (4). The No. 1 rotating motor (6) with the rotating end protruding from the upper surface of the worktable A (1), the support platform (7) set on the rotating end of the No....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com