Power battery housing assembly for electric automobile

A pure electric car and power battery technology, applied in the direction of electric power devices, power devices, vehicle parts, etc., can solve the problems of difficult uniform glue coating and sealing, connectors affecting sealing, and difficult glue coating, etc., to achieve the benefit of coating Uniformity and sealing of the glue, ensuring the sealing performance, and reducing the difficulty of glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

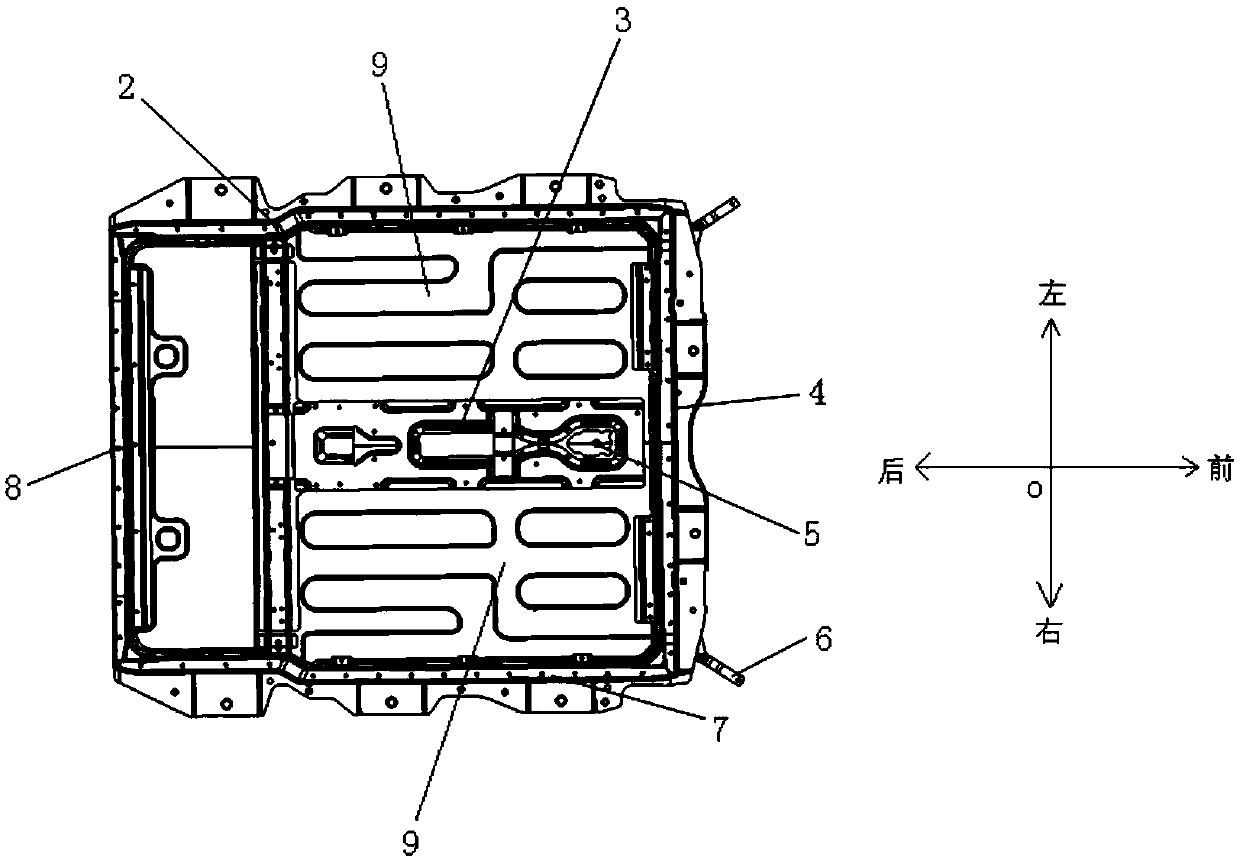

[0031] For clarity, the following description will be combined with a Cartesian coordinate system, in which whether in the front-to-rear direction or the left-to-right direction, the side closer to the origin O is the inner side, and the side further away from the origin O is the outer side.

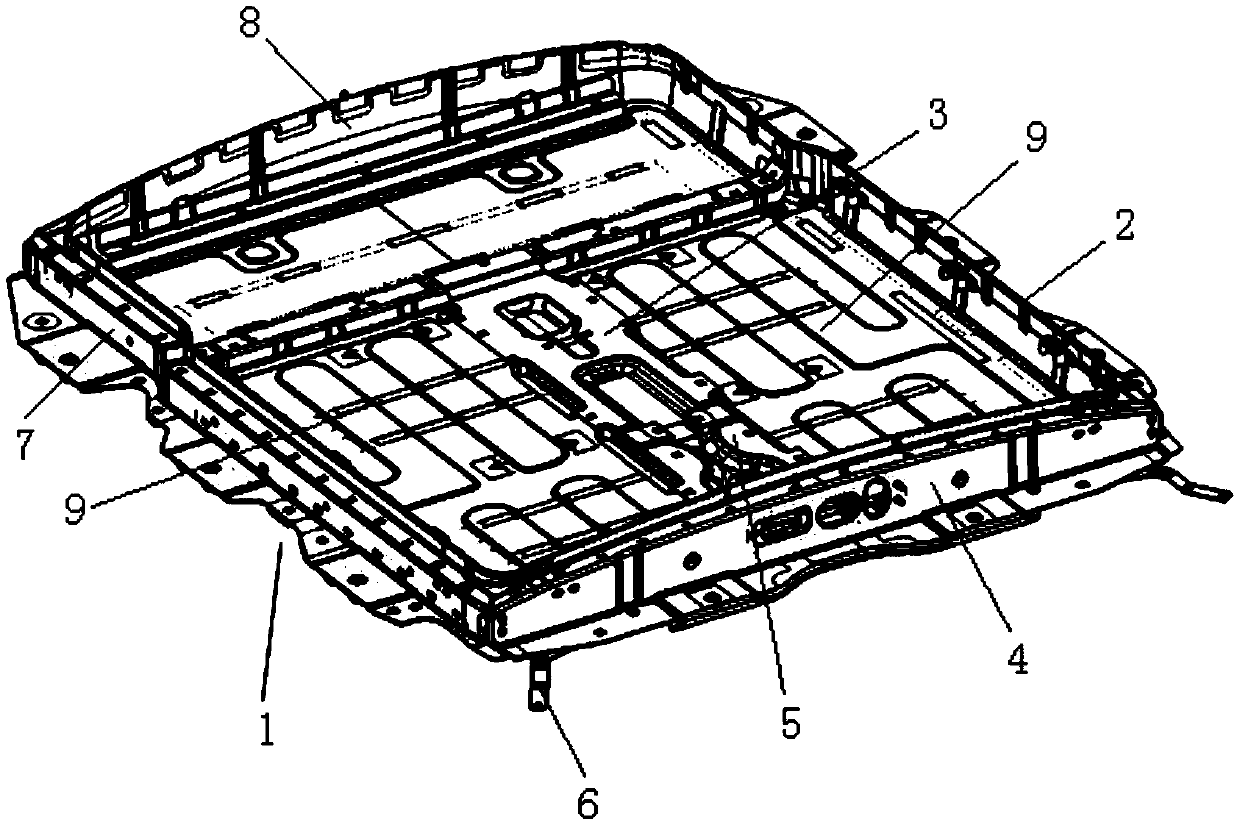

[0032] reference figure 1 , The power battery housing assembly 1 of a pure electric car is used to arrange the power battery in the bottom space of the car.

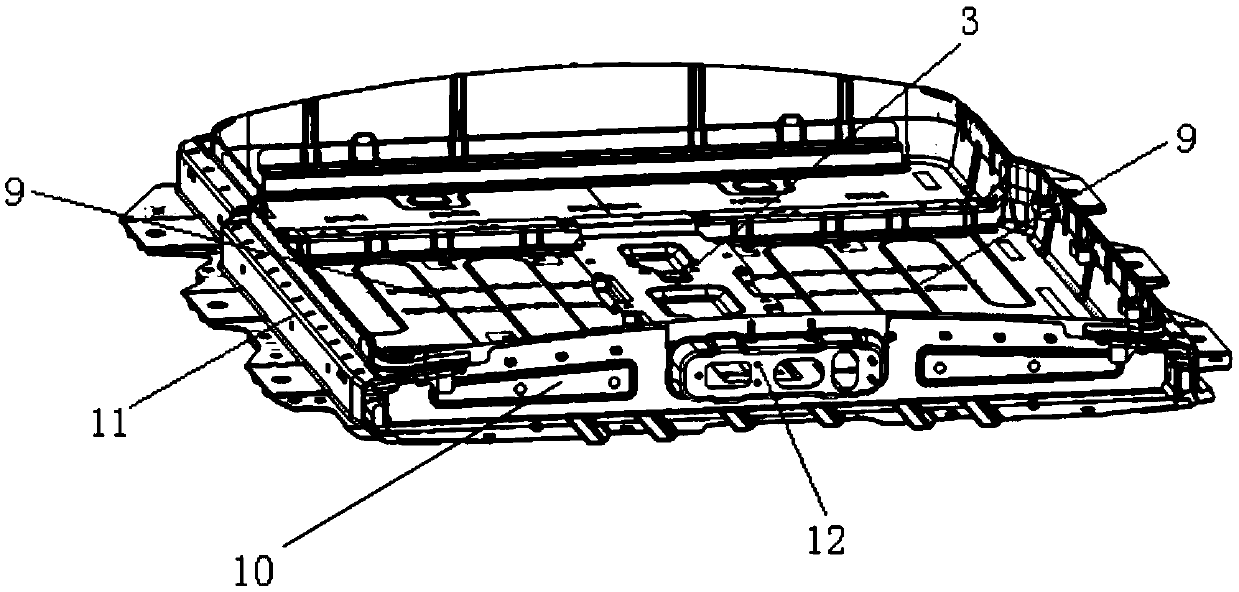

[0033] reference figure 2 In this embodiment, the power battery housing assembly 1 uses at least two bottom plates 9, and the two bottom plates 9 are connected by the middle longitudinal beam 3 and the tray 5. When the middle longitudinal beam 3 and the tray 5 are not present, a whole bottom plate 9 can also be used. In this embodiment, the middle longitudinal beam 3 is a sealed box-shaped structure, which can strengthen the structural strength of the power battery housing assembly 1. The upper surface of the middle longitudinal beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com