Planetary differential all-terrain track wheel structure

A crawler wheel and all-terrain technology, which is applied to crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of inability of all-terrain vehicles to travel, poor ability to cross the vertical wall, and increase production costs, so as to improve driving safety. Reliability, reasonable structure design, improve the effect of passing the vertical wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

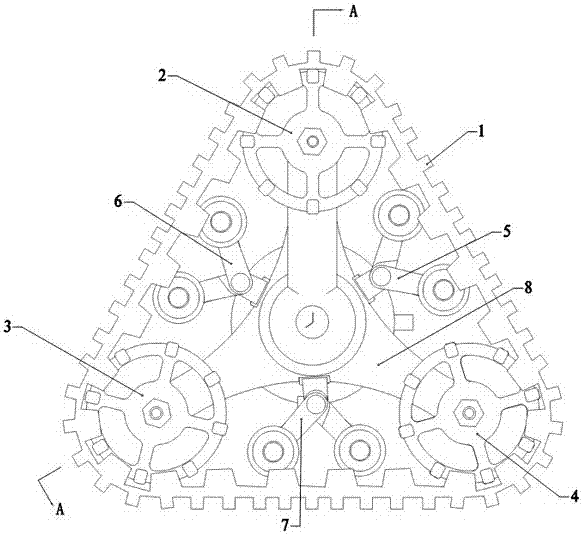

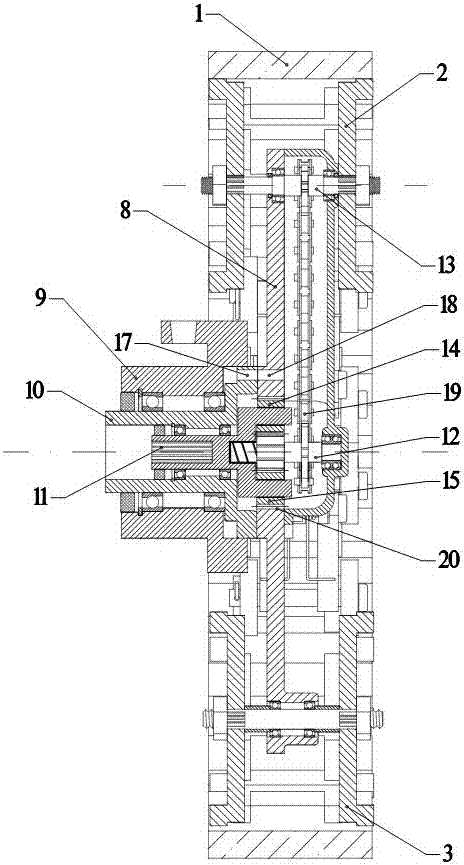

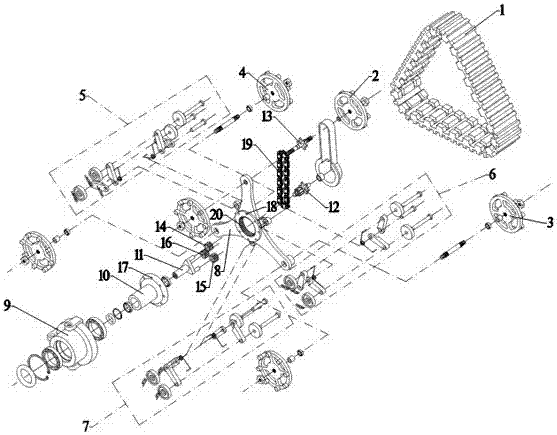

[0025] The present invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the planetary differential all-terrain track wheel

[0026] Structure, including planetary differential mechanism, track wheel mechanism and transmission connection mechanism. The transmission connection mechanism is mainly composed of a main support, a steering knuckle, a main support connection plate, a central shaft, a transmission shaft and a transmission chain. An inner ring gear is arranged on the inner wall of the center of the main bracket, and the connecting plate of the main bracket is coaxial with the inner ring gear and fixedly connected by threads to form the support of the planetary differential mechanism inside, and the planet carrier is in the shape of three claws , the first planetary gear, the second planetary gear and the third planetary gear are respectively set on the three claws, and the planetary gears are uniformly arranged at the circumferential posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com