Three-layer oil tank

A technology for oil tanks and outer tank walls, applied in the field of gas station safety and environmental protection equipment, can solve problems such as underground environmental pollution, business loss, and large engineering volume, and achieve the effects of saving manpower and material resources, avoiding pollution, and preventing corrosion and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0020] The three-layer oil tank with interlayer space of the present invention is transformed into a three-layer wall storage tank on the basis of the existing single-layer wall storage tank, and a three-dimensional fabric layer with two interlayer spaces is formed on the inner surface of the single-layer wall, It not only provides an installation space for the installation of the leakage monitoring system, but also strengthens the strength of the tank wall.

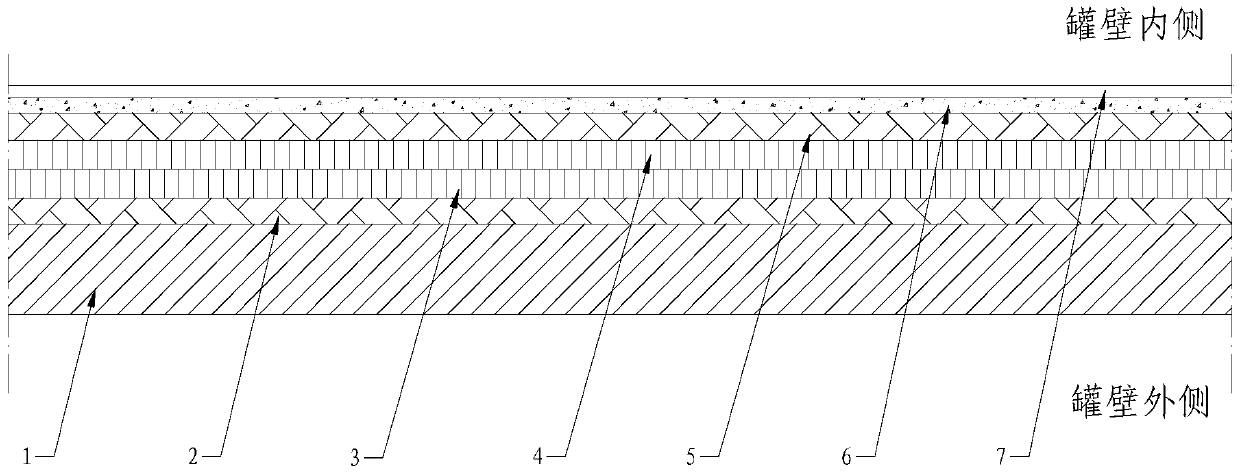

[0021] figure 1 It is a sectional view of the tank wall of the three-layer oil tank of the present invention. like figure 1 As shown, the tank body of the oil tank is formed by the tank wall, and the outermost layer of the tank wall is the tank wall 1 of the existing single-layer oil tank, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com