Automatic storing and taking equipment for mushroom cultivation frames

A technology for automatic storage and cultivation of frames, applied in the field of agricultural machinery, can solve the problems of low work efficiency and high work intensity, and achieve the effects of saving space, improving work efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

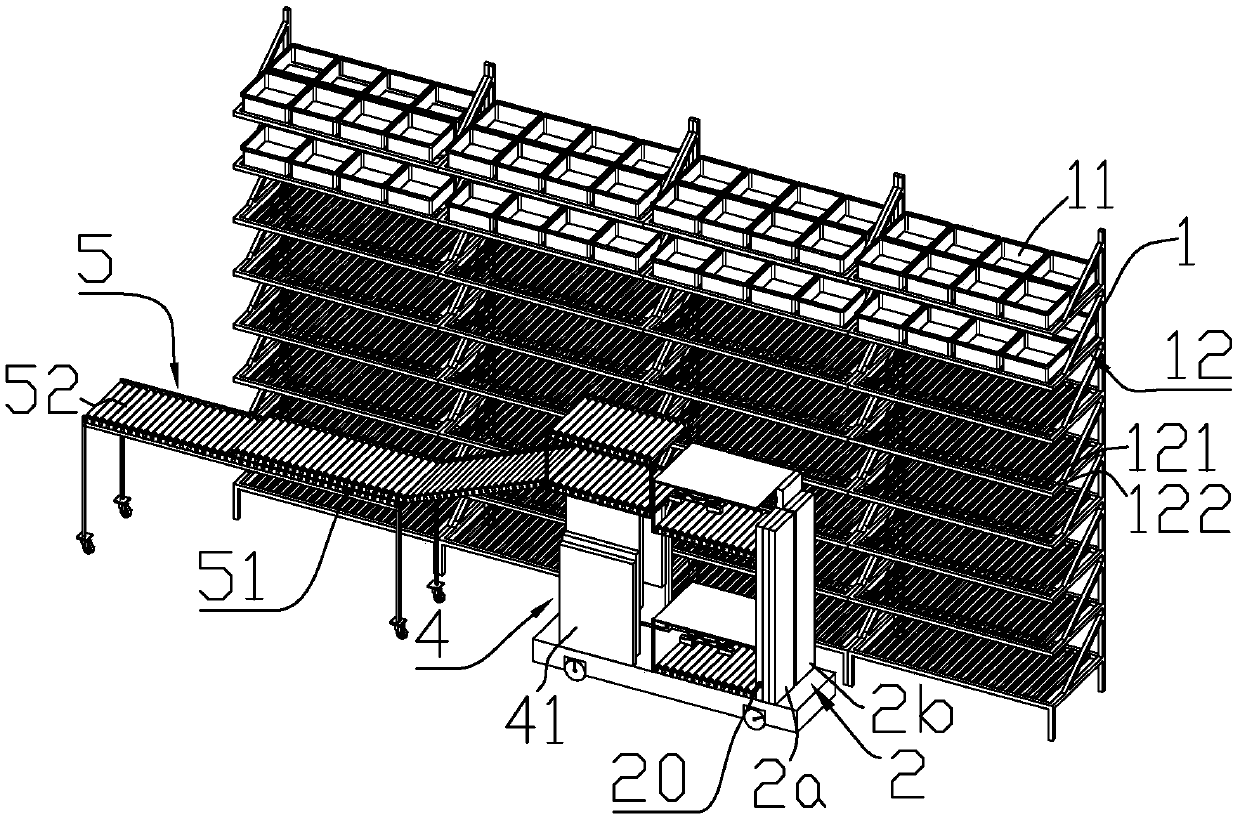

[0042] refer to Figure 1 to Figure 18 , an automatic access device for mushroom cultivation frames, comprising shelves 1 and mushroom cultivation frames 11, roadways are formed between two adjacent shelves 1, and cultivation frames 12 with a set number of layers are arranged on each shelf. The mushroom cultivation frame 11 is located in the cultivation frame, and the automatic access equipment also includes a transport trolley, which is located in the roadway, and the transport trolley includes a front access unit 2, a rear transfer unit 4 and a conveying trolley. Agency 5;

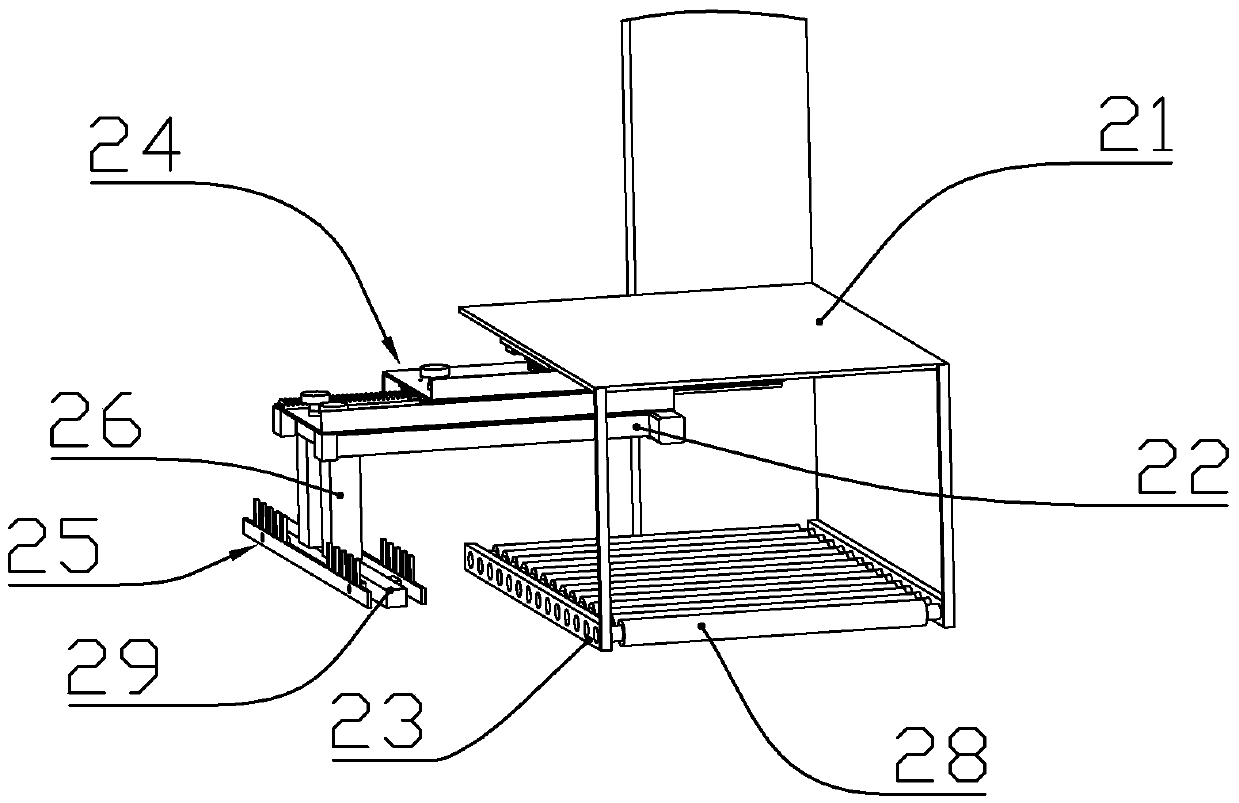

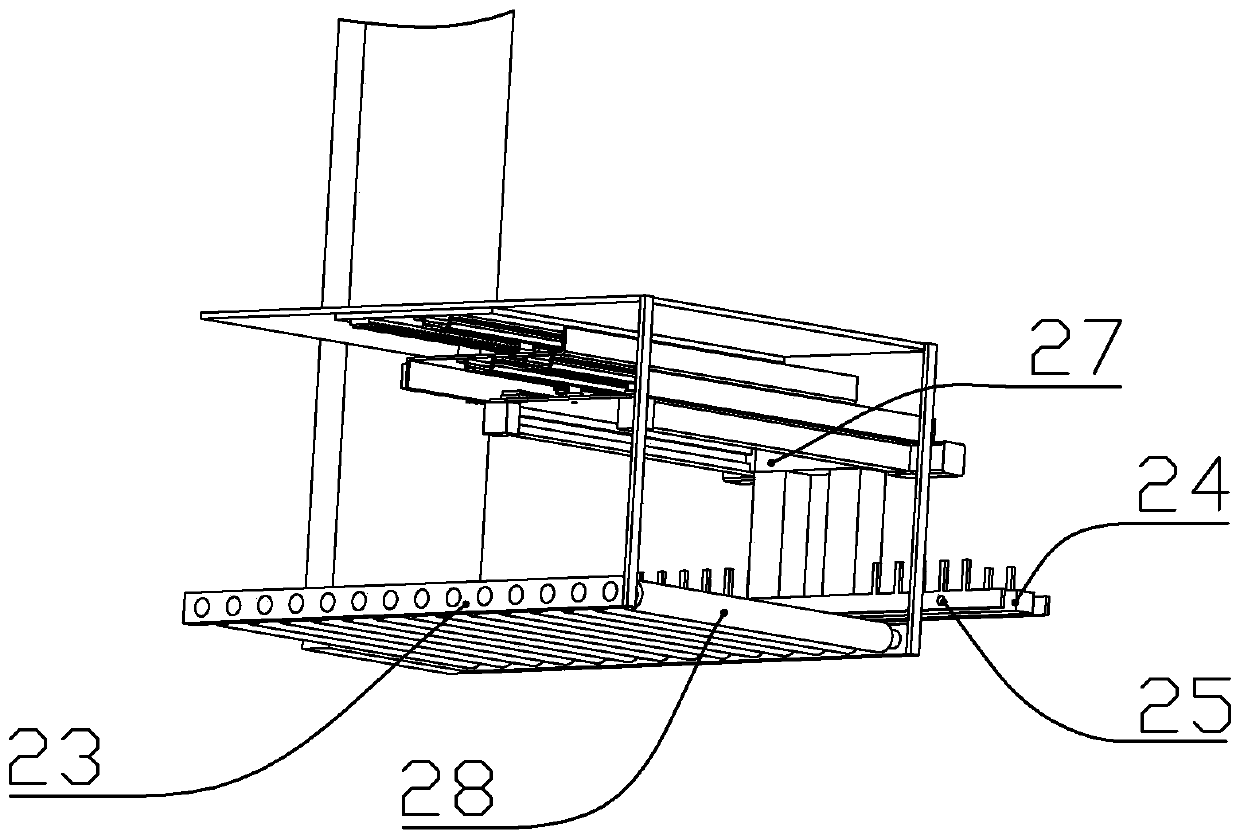

[0043] The front access unit includes a lift mechanism 20 and an access frame, the access frame is fixed on the upper part of the action end of the lift mechanism, and the access frame includes two rods arranged along the front and rear directions and with uniformly arranged small holes. The cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com