Power and free overhead conveyer

A suspended conveyor, accumulation and release technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of energy saving and decoupling of lifting claws, and shorten the length of the trolley, reduce friction, and lengthen it. The effect of trolley length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

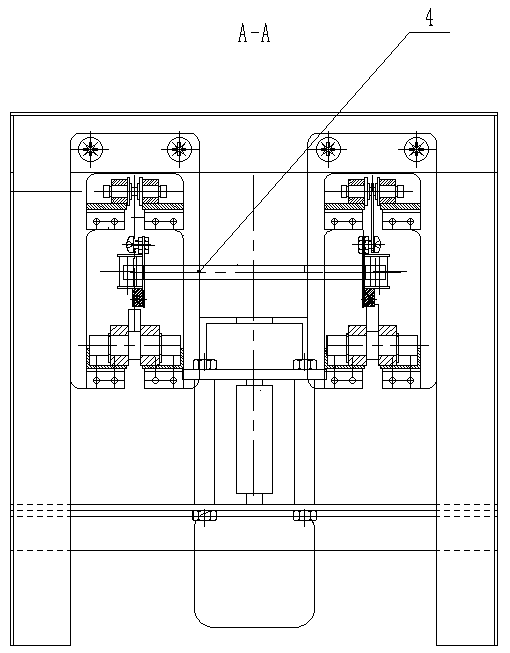

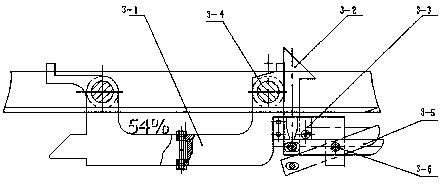

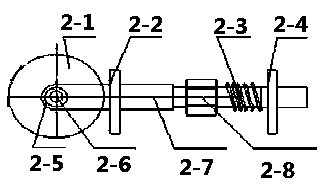

[0035] In the figure, an accumulative and free suspension conveyor of the present invention is mainly composed of a fast chain frame 1, a sprocket device 2, a drive wheel 2-1, a mounting seat 2-2, a top pressure spring 2-3, and an adjustment seat 2. -4. Drive shaft 2-5, pressure feedback sensor 2-6, hydraulic cylinder 2-7, spring seat 2-8, suspension conveyor 3, transport trolley 3-1, lifting claw 3-2, sliding cover 3- 3. Transport wheel 3-4, front shovel 3-5, rotating shaft 3-6, support assembly 4, fast chain traction track 5, fast chain bearing track 6, slow chain frame 7, slow chain traction track 8, The slow chain carries track 9.

[0036]As shown in the figure; a kind of accumulation type suspension conveyor, described conveyor comprises fast chain frame 1, suspension conveyor 3 and slow speed chain frame 7 and control system; Described fast chain frame 1 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com