Slag scrap-away device of electroplating oil-water separating device

A technology of oil-water separation device and slag scraping device, applied in liquid separation, separation method, grease/oily substance/float removal device, etc., can solve the problem of labor-intensive, difficult to remove emulsified oil and dispersed oil, and incomplete oil-water separation and other problems, to achieve the effect of improving oil removal efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

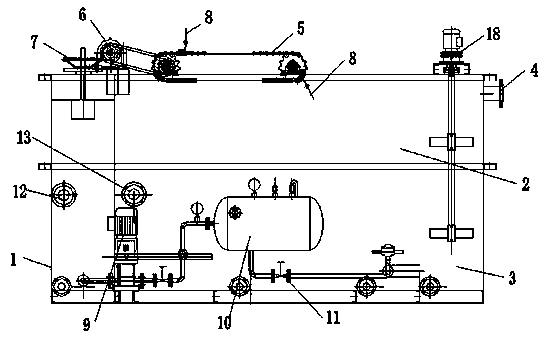

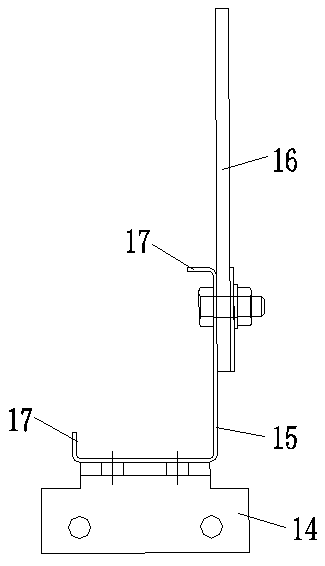

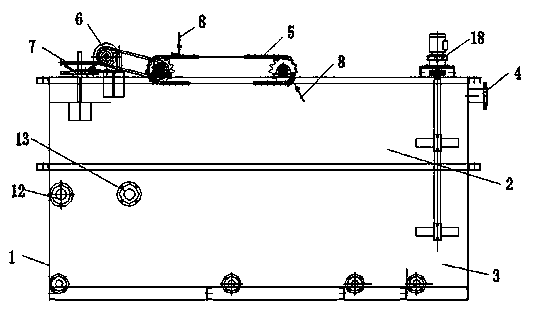

[0014] Combine below Figure 1 to Figure 3 Specific description embodiment:

[0015] Such as Figure 1 to Figure 3 As shown, an electroplating oil-water separation device, the electroplating oil-water separation device includes a body 1, the body 1 is divided into an oil-water separation area 2 and a release area 3, and the outer wall of the oil-water separation area 2 is connected with an inlet Barrel 4; said main body 1 is provided with crawler belt circulation transmission device 5, and described crawler belt circulation transmission device 5 is connected with reducer device 6 and controller 7, and described crawler belt circulation transmission device 5 is provided with several scrapers A slag device 8; an air-water pump 9 and an air-water dissolver 10 are arranged in the release area 3, and the air-water pump 9 can pump gas and liquid medicine into the air-water dissolver 10 for mixing, and the mixed gas-water dissolver 10 The water mixture is released into the oil-wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com