An italic oxidation ditch

An oxidation ditch and body-style technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problem of large equipment footprint, poor denitrification effect, sludge Easy to settle and other problems, to achieve the effects of less land occupation, reduced suspended matter (SS) content, and large effective water depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

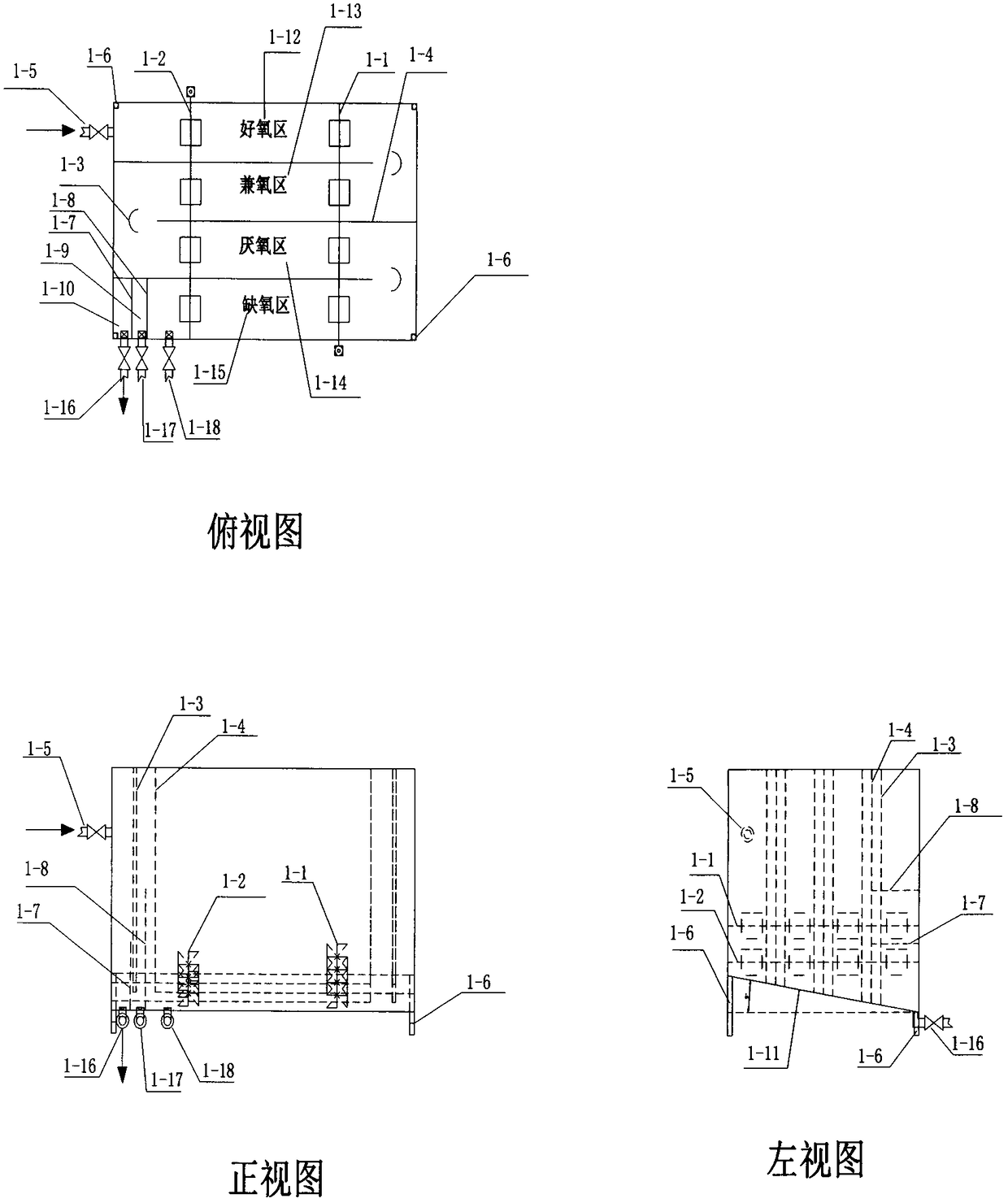

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] figure 1 It is a schematic diagram of equipment connection of the present invention.

[0033] Such as figure 1 As shown, the present invention provides an italic type oxidation ditch, mainly comprising: aerobic pool 1-12 connected in series, facultative oxygen pool 1-13, anaerobic pool 1-14, anoxic pool 1-15, secondary sedimentation Pool 1-9 and clear water pool 1-10; described aerobic pool 1-12, facultative oxygen pool 1-13, anaerobic pool 1-14, anoxic pool 1-15, secondary sedimentation pool 1-9 and clear water Pools 1-10 are combined to form an italic oxidation ditch.

[0034] The italic oxidation ditch passes through three arc-shaped diversion walls 1-3, three linear diversion walls 1-4, one fixed overflow weir 1-7 and one mobile overflow weir 1-8 It is divided into aerobic pool 1-12, facultative pool 1-13, anaerobic pool 1-14, anoxic pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com