Novel house capable of being assembled through insertion connection and assembling method thereof

A new type of house and interface technology, which is applied in the direction of architecture and building construction, can solve the problems of heavy weight, expensive red bricks, poor reusability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

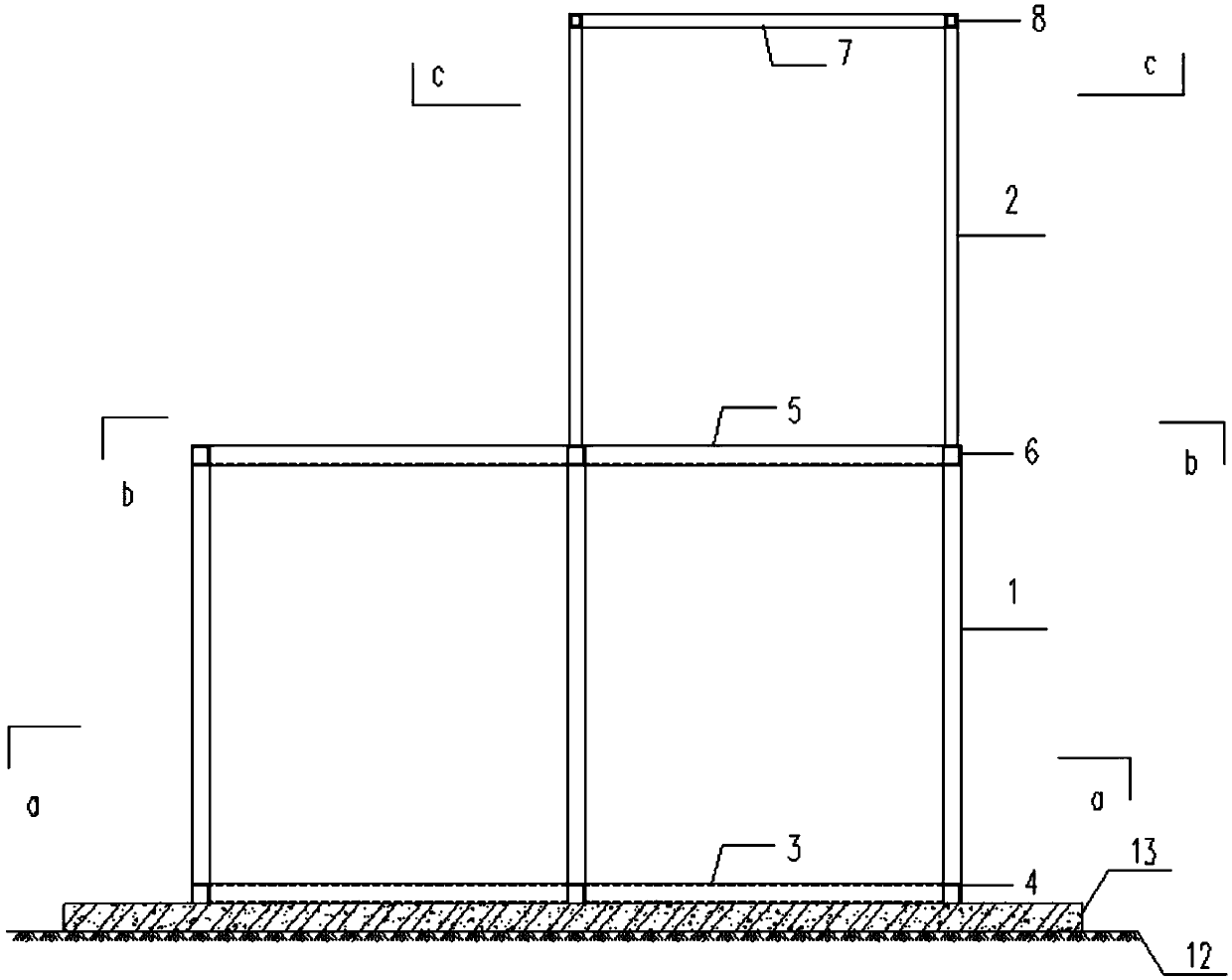

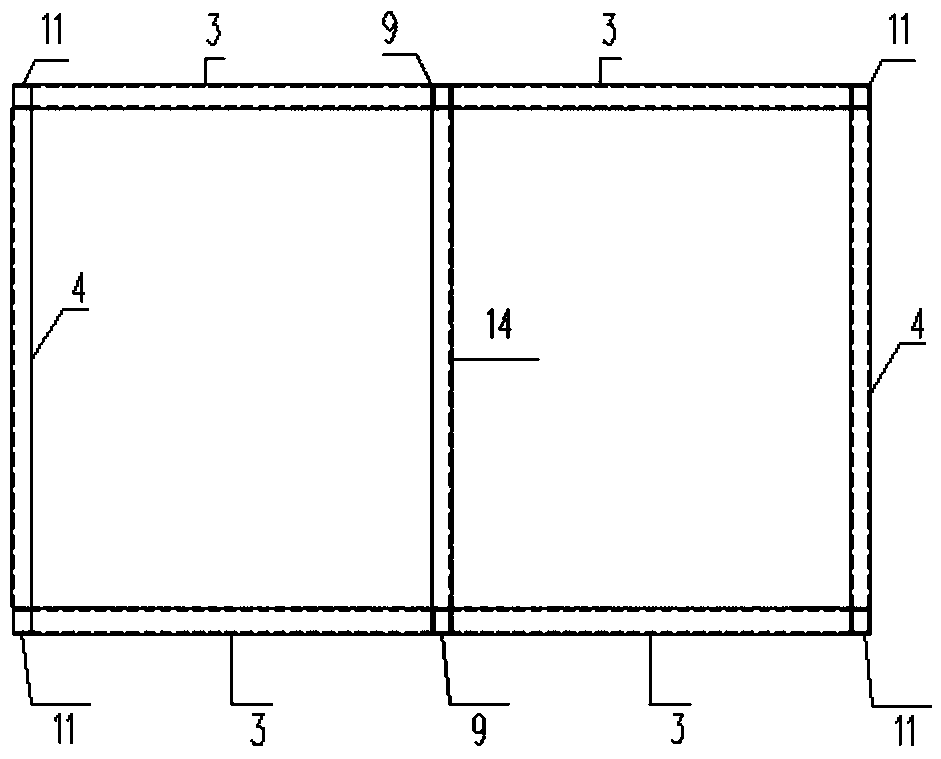

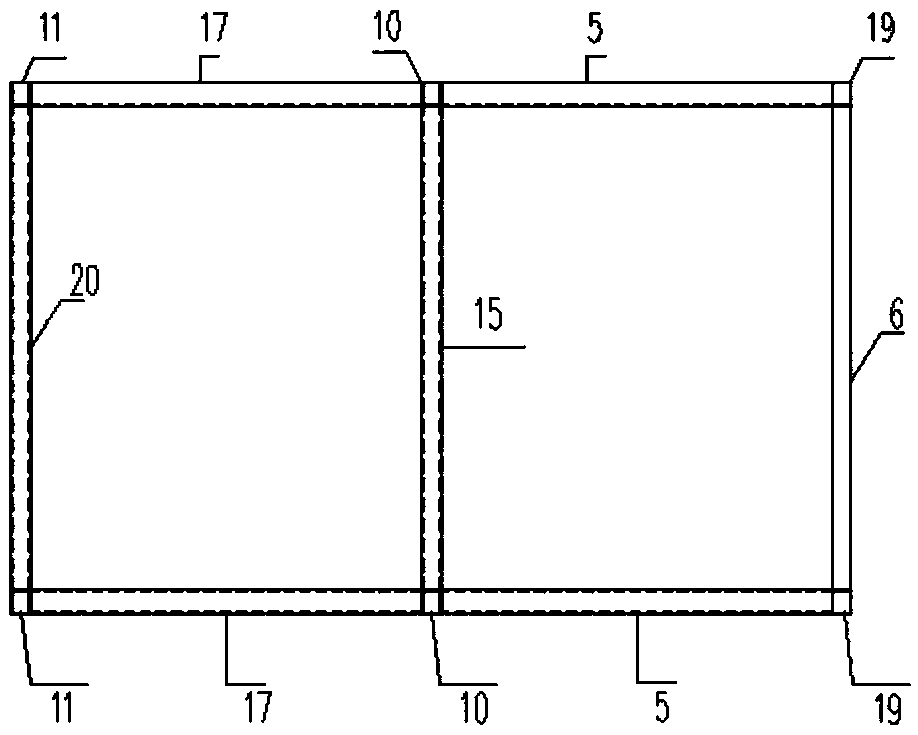

[0059] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0060] Such as Figure 1 to Figure 4 As shown in the figure, first floor column 1, second floor column 2, ground beam 3, ground beam 4, second floor beam 5, second floor beam 6, second floor roof beam 7, second floor roof beam 8, bottom Four-way joint 9, five-way joint 10, three-way joint 11, compacted plain soil 12, waterproof concrete cushion 13, centered ground stringer 14, centered stringer 15 on the second floor, first-floor roof beam 17, corner four Connecting joint 19, one deck roof stringer 20, main steel pipe 21, auxiliary steel pipe 22, nut 23, screw rod 24, middle wallboard 25, end wallboard 26, channel steel block 27, angle steel block 28, roof panel 29.

[0061] A new type of house that can be plugged and assembled, including connected steel roof trusses on the first floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com