Downhole tube for coil coupling control of electromagnetic valve

A coupling control and solenoid valve technology, applied in the direction of drilling pipe, casing, drilling equipment, etc., can solve the problems of easy aging, damage, and affecting the normal running of other tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with the accompanying drawings of the description.

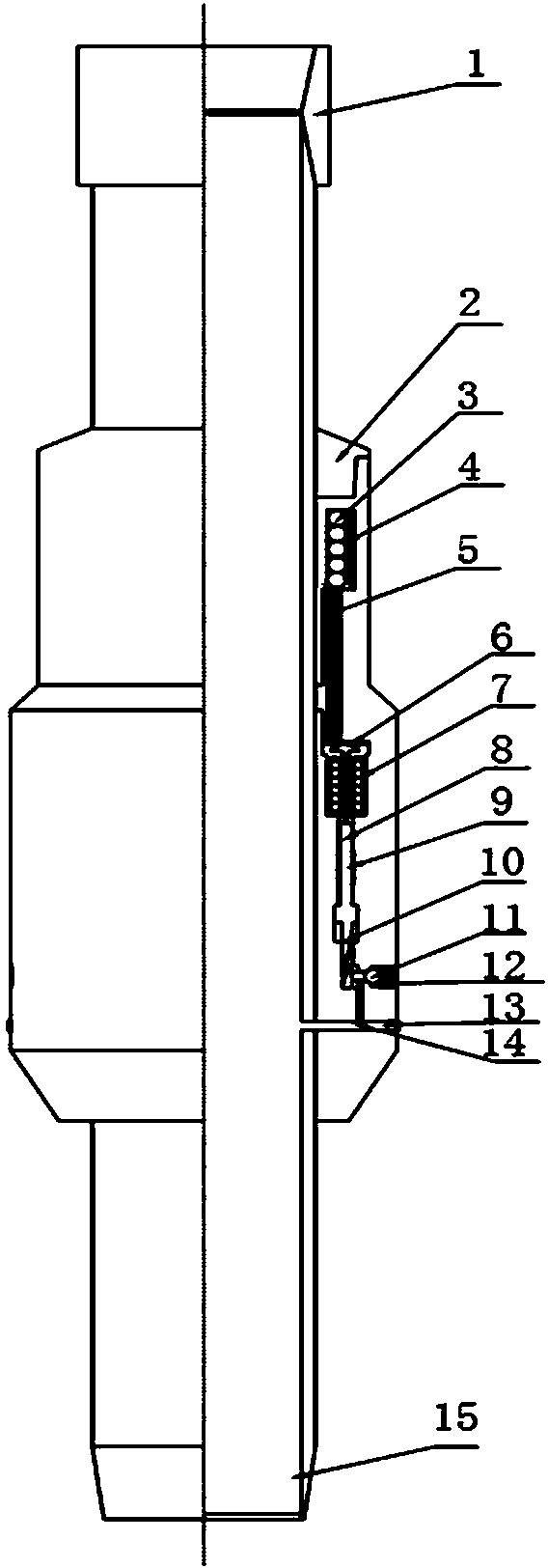

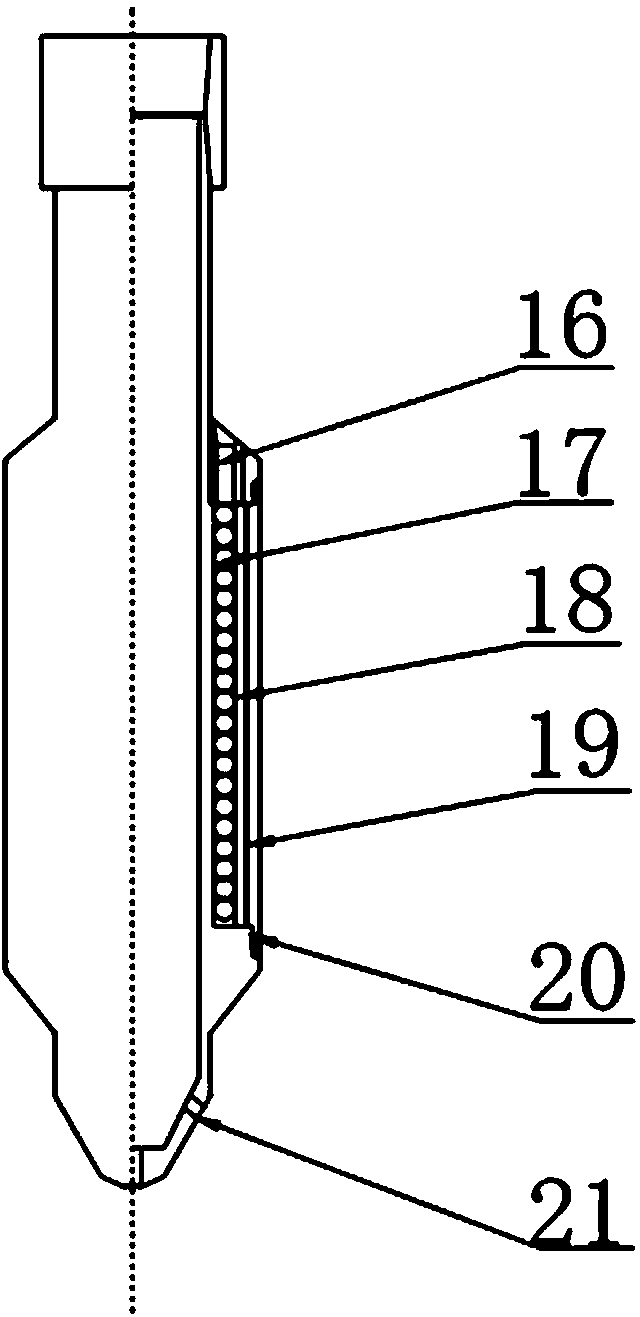

[0020] Such as figure 1 , 2 As shown, a downhole tubing for a coil coupling control solenoid valve of the present invention includes two parts, an outer tubing and an inner tubing. Among them, there is a pier rough section between the threaded buckles at both ends of the outer pipe, and a coupling coil 3, a transmission cable 5, a terminal block 6, a solenoid valve 7, a drive rod 8, and an anti-push ring 9 are arranged in sequence in the axial direction in the upsetting section. And the liquid inlet channel 14. Among them: coupling coil 3, transmission cable 5, terminal board 6, solenoid valve 7, drive rod 8, and anti-push ring 9 are sealed in the upsetting section. Baffle or cover cover (such as figure 2 shown); the liquid inlet channel 14 is in the shape of "up", and the upper liquid inlet channel is provided with a control ball 11 and a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com