Scroll compressor and control method thereof

A scroll compressor and compression chamber technology, applied in the field of compressors, can solve the problems of increased power consumption, long suction channel, leakage, etc., and achieve the effects of increasing power consumption, avoiding air leakage, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 is the first embodiment of the scroll compressor of the present invention.

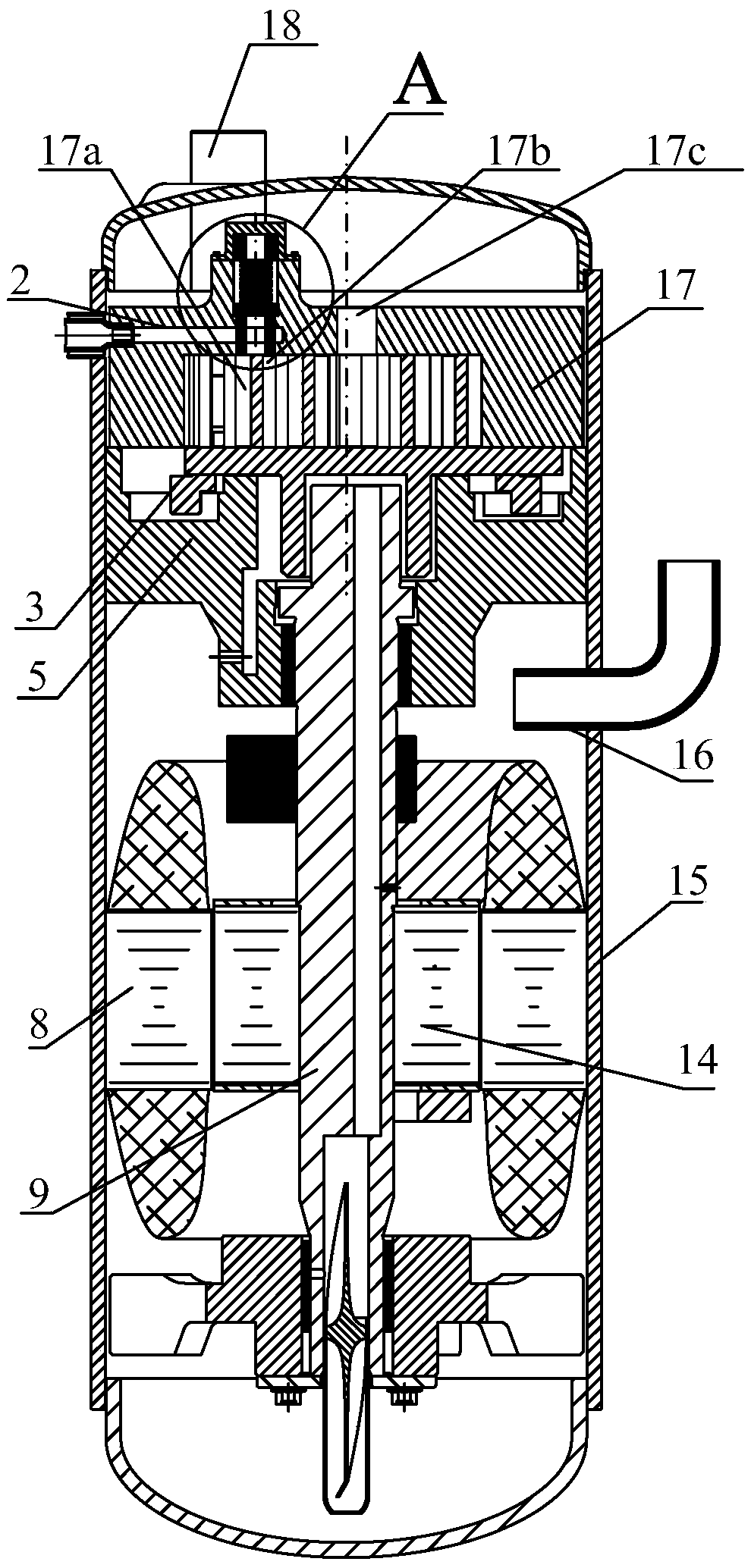

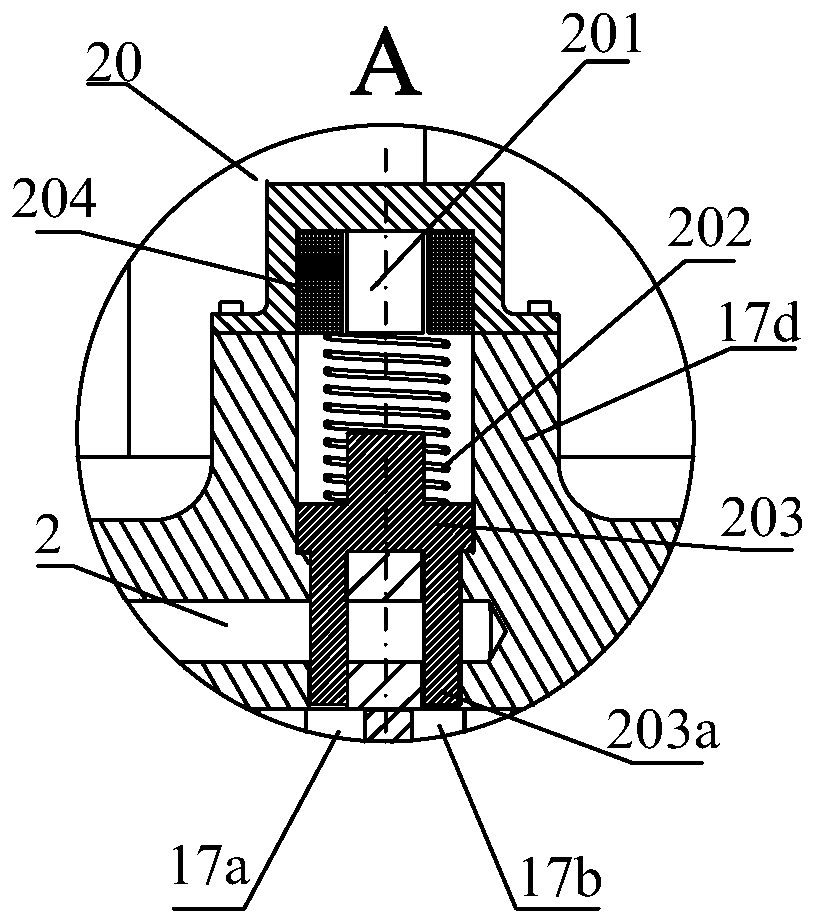

[0035] Such as Figure 1a As shown, the scroll compressor includes a casing 15, and the casing 15 is provided with a driving motor, a crankshaft 9, a movable scroll 3, and a fixed scroll 17; The scroll 3 is connected to drive the movable scroll 3 to rotate. The movable scroll 3 is provided with a movable scroll body, and the fixed scroll 17 is provided with a stationary scroll body (not shown in the figure), and energy is formed between the movable scroll body and the stationary scroll body. The first compression chamber 17a and the second compression chamber 17b that are alternately intake and exhaust; the housing 15 is provided with a suction pipe 18 and an exhaust pipe 16, which are used to supply gas to the two compression chambers and compress the The gas of the scroll compressor is discharged from the compressor, and the scroll compressor also has an enthalpy-increasing inta...

Embodiment 2

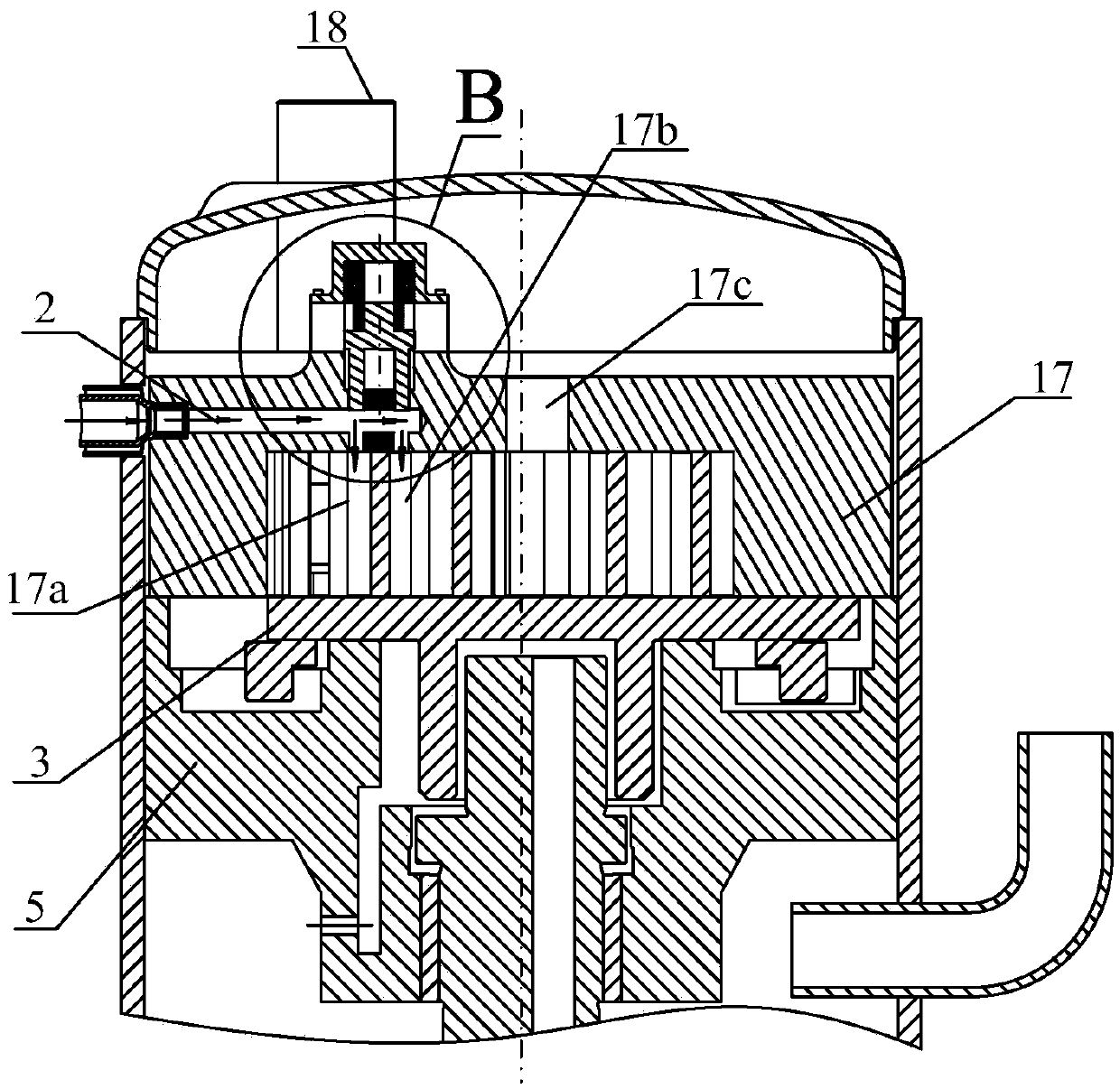

[0041] Embodiment 2 is another embodiment of the scroll compressor of the present application. Compared with Embodiment 1, the difference lies in the structure of the control device. Such as Figure 3a , 3b , 4a, and 4b, in this embodiment, the control device includes a control valve 30 and a three-way valve 26, wherein the control valve includes a cylinder and a piston 303; at least part of the cylinder is formed on the fixed base 17d of the fixed scroll 17 Above, the piston 303 is slidably arranged in the cylinder, an air chamber 305 is formed between the piston 303 and the cylinder, and the piston 303 is used to simultaneously open the first connecting channel 17e and the the second connecting passage 17f, or close at least one of the first connecting passage 17e and the second connecting passage 17f; the first end 26a of the three-way valve 26 is connected to the exhaust pipe 16, and the second The end 26b is connected to the suction pipe 18 , and the third end 26c is co...

Embodiment 3

[0046] Embodiment 3 relates to a control method for a scroll compressor, the scroll compressor includes a first compression chamber and a second compression chamber capable of alternating intake and exhaust, and an enthalpy-increasing intake passage; The method includes: communicating the first compression chamber and the second compression chamber with the enthalpy-increasing intake passage when increasing enthalpy, and disconnecting the first compression chamber from the second compression chamber when turning off enthalpy increasing The connection between the two compression chambers. Through such control, the two compression chambers can be supplemented with enthalpy increase when the enthalpy is increased, and the problem of cross-gas generation between the two compression chambers due to the pressure difference can also be avoided when the enthalpy increase is turned off.

[0047] Preferably, when the enthalpy increase is turned off, at least one of the first compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com