A drum-shaped self-aligning coupling type inverted umbrella surface exposure machine

A technology of surface aerator and drum, which is applied in water aeration, mechanical equipment, water/sludge/sewage treatment, etc. It can solve the problems of short service life, difficult to salvage the impeller, and increase the force load of the reducer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Further description will be made below in conjunction with drawings and embodiments.

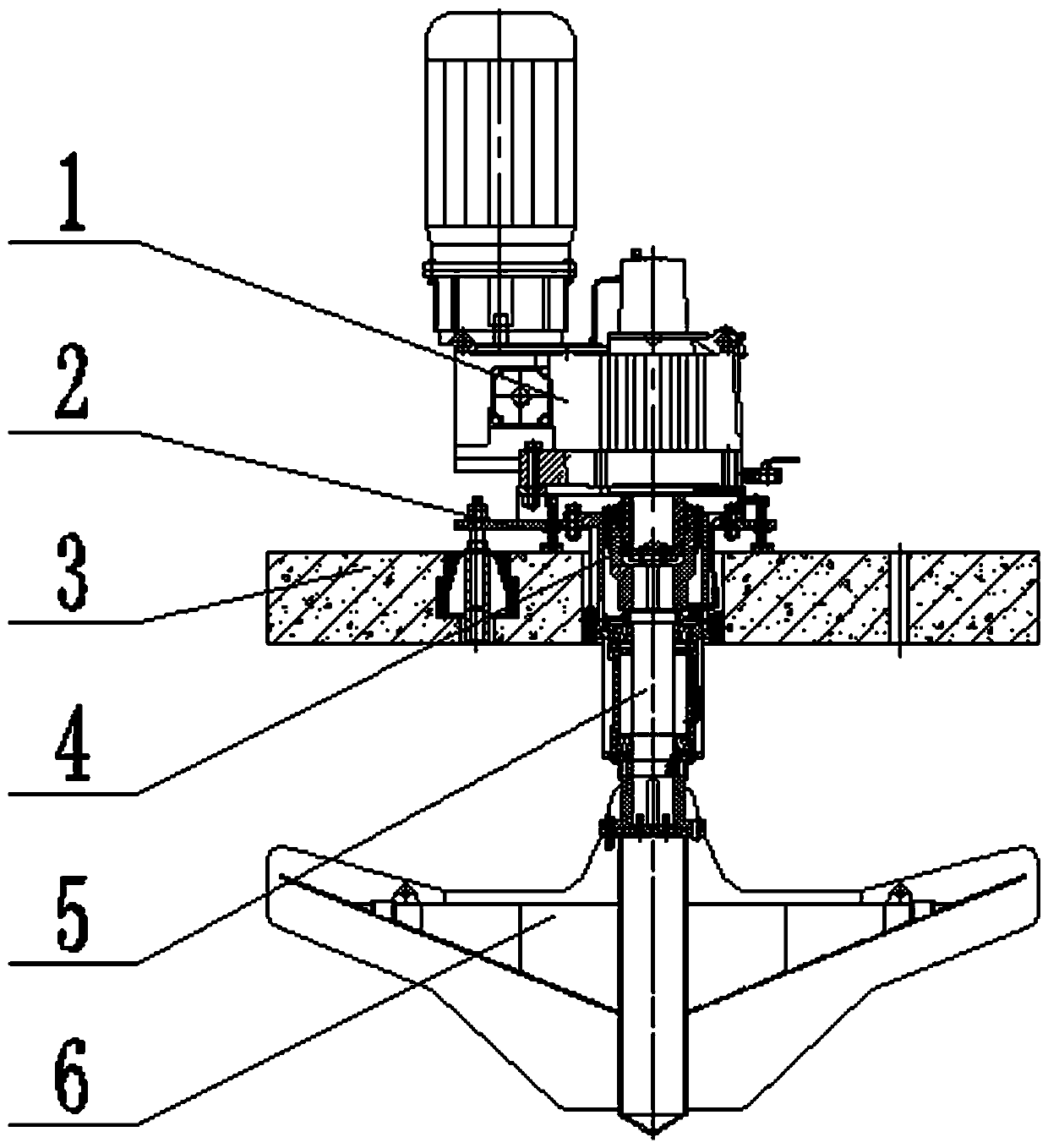

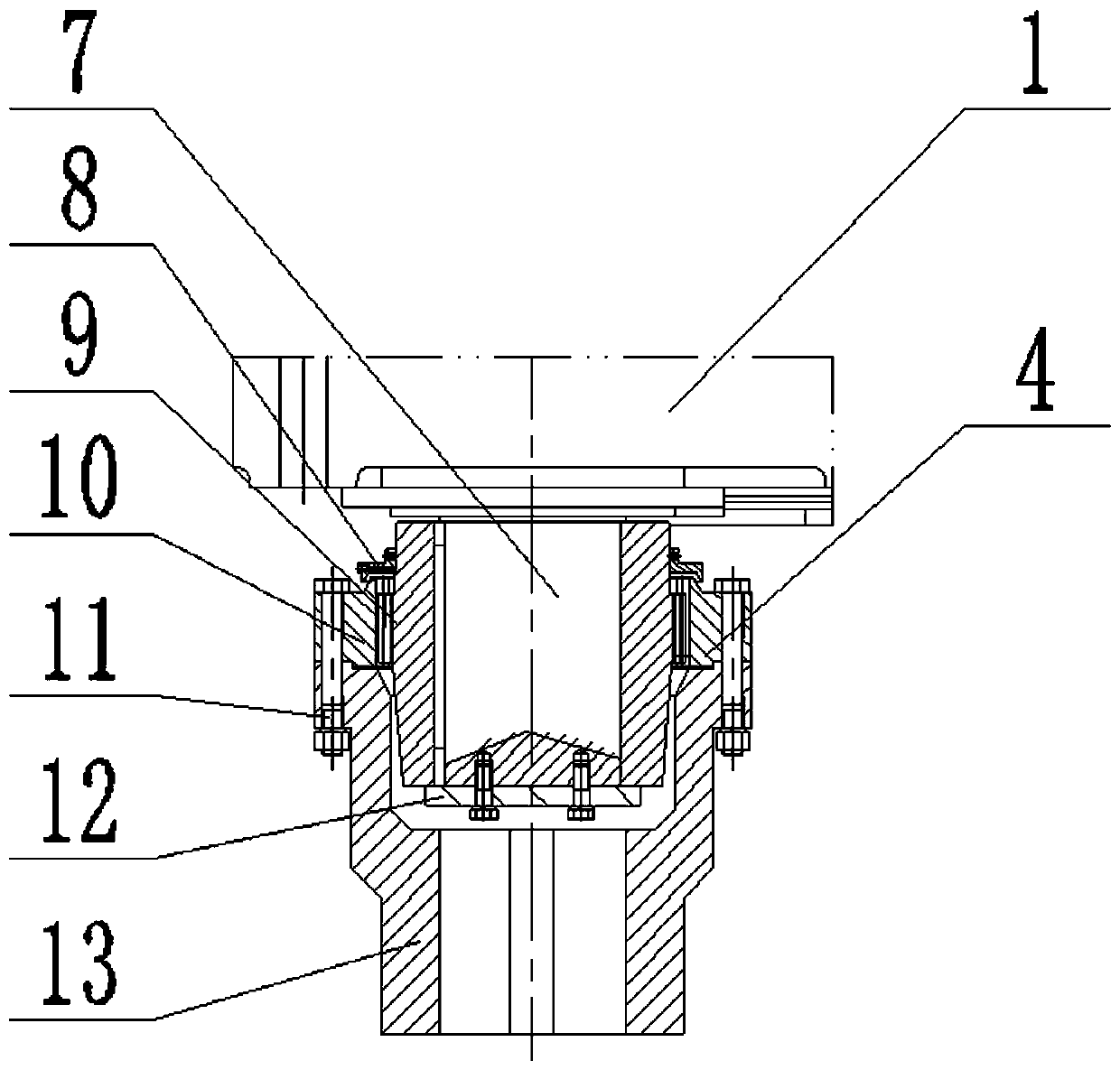

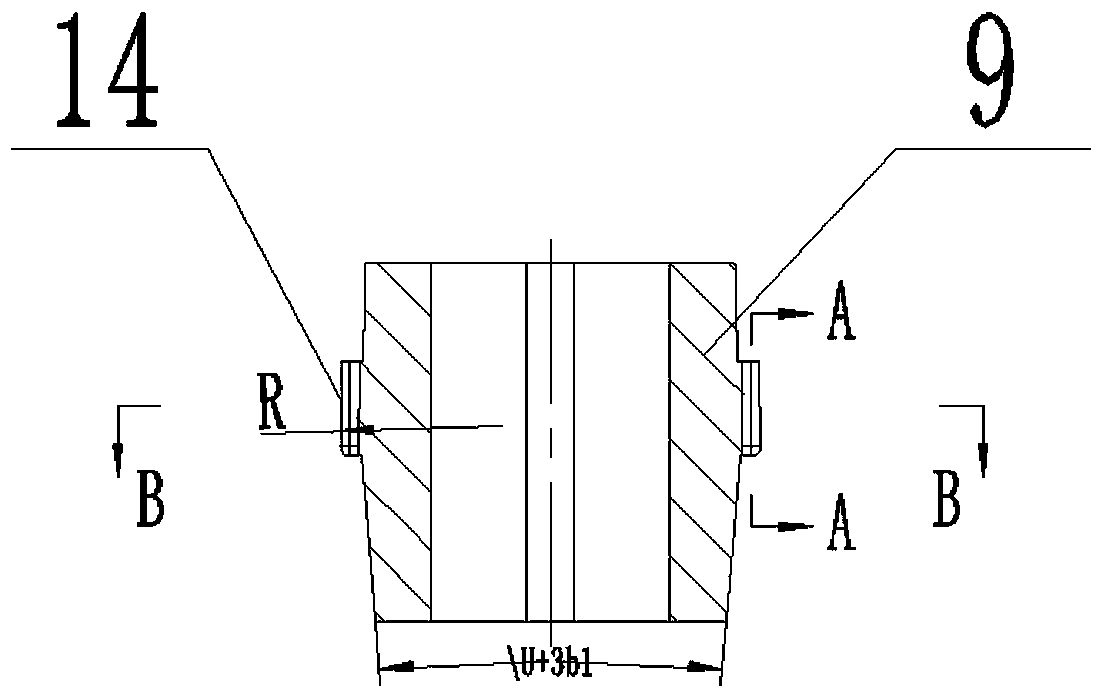

[0042] Such as figure 1 , the present invention is a drum-shaped self-aligning coupling type inverted umbrella surface exposure machine, including a speed reduction mechanism 1, an installation base 2, an installation base 3, a drum-shaped self-aligning coupling device 4, a transmission shaft seat 5 and an impeller 6 , the whole is divided into three layers, the upper layer is the reduction mechanism components, the middle layer is the installation parts composed of the installation base and the installation foundation, the lower layer is the transmission shaft seat and impeller components, and the drum-shaped self-aligning coupling device connects the output shaft of the reducer and the transmission shaft Transitionally connected, as the link between the shaft and the shaft, the installation base 2 and the installation base 3 are connected as a whole by bolts, the reduction mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com