Method for controlling synchronous motor low speed sensorless based on self-adaptive filter

A technology of adaptive filter and synchronous motor, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., can solve the problems that the performance of the estimator is greatly affected, and the parameter design process of the speed estimator is complicated. Achieve the effect of enhancing low frequency attenuation ability and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

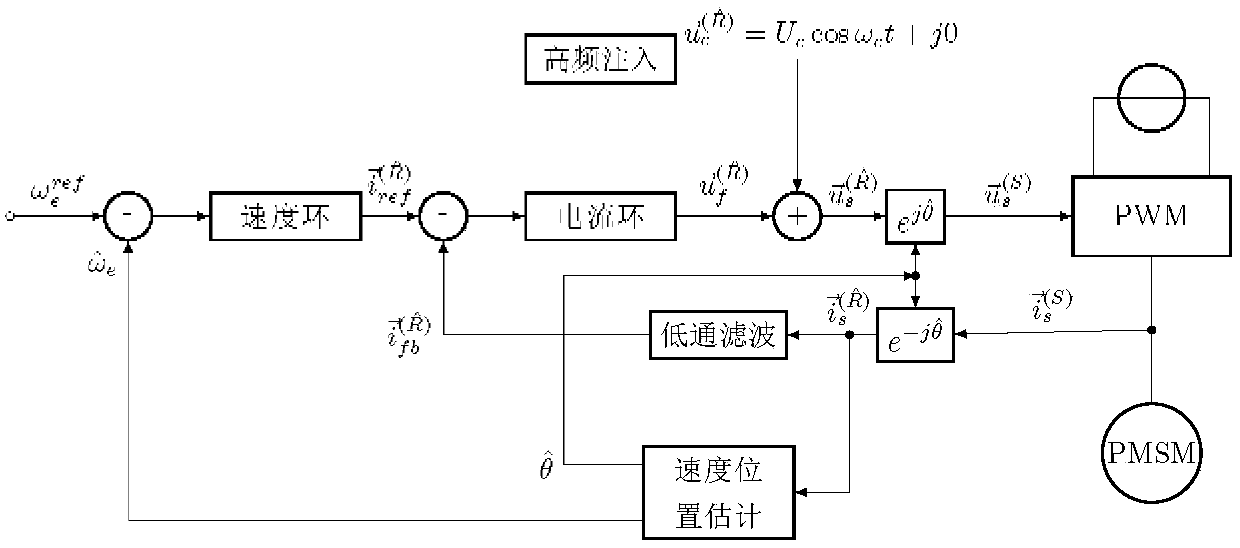

[0039] Such as figure 1 As shown in the block diagram of the permanent magnet synchronous motor sensorless control structure based on pulse vibration high-frequency voltage injection, the speed and position estimation module replaces the traditional photoelectric encoder and position sensor to provide the motor rotor position signal required for motor vector control, and the speed Motor rotor speed signal required for closed-loop control. In sensorless control, the real spatial position of the rotor is unknown, and the angles involved in the rotation transformation are estimated angles, so each physical quantity is the physical quantity in the estimated two-phase rotating coordinate system with a superscript Indicates; the physical quantity in the stationary coordinate system is superscripted (S) Represents; estimated motor rotor position and the estimated speed Given by the speed position estimation module, the rotation factor and Indicates the coordinate transforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com